Groove type ironing machine

An ironing machine and trough-type technology, which is applied in the field of ironing machines, can solve problems such as uneven heat distribution in semicircular troughs, deviations between ironing effects and ironing requirements, bevel angles of linen, etc., and achieve ingenious structural adjustment and design , to ensure the quality of ironing, to solve the effect of technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

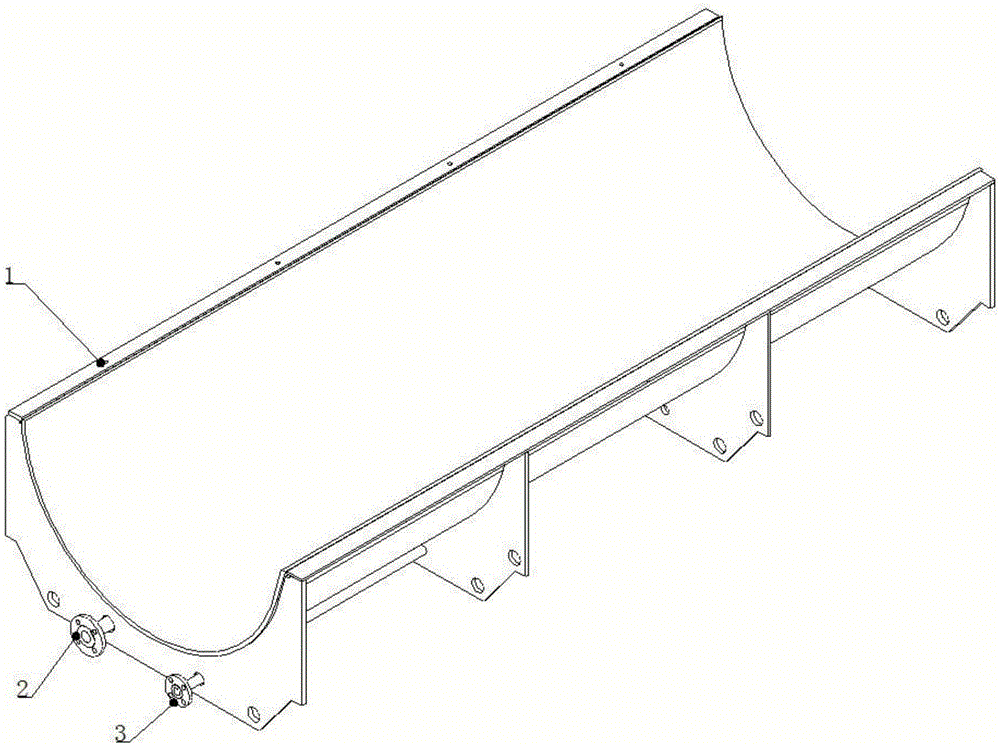

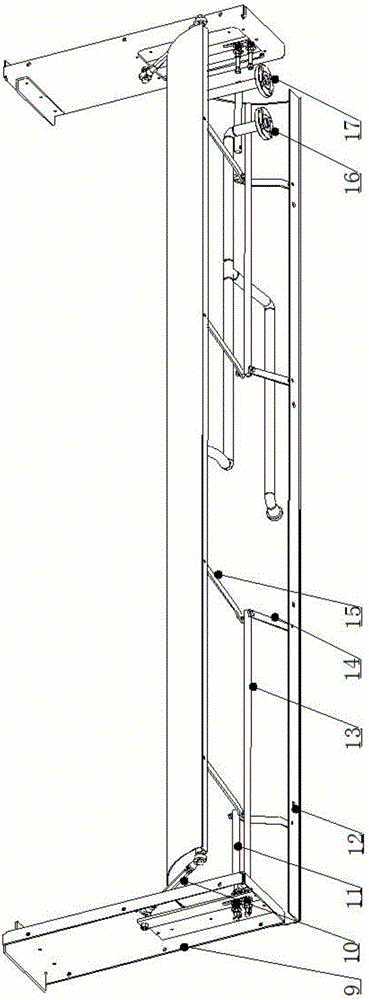

[0072] see Figure 1-Figure 5 , a trough ironing machine, the biggest difference from the common trough ironing machine is that it combines the characteristics of the rigid trough and the flexible trough, and the rigid trough and the flexible trough are used together, and the size of the frame installation is consistent. Now combined with the attached drawings Further explanation:

[0073] From figure 1 You can see the steam inlet 2 and the condensed water outlet 3 of the rigid tank. The steam flows through the steam chamber of the rigid tank to transfer heat to the tank body. In this picture, the linen enters from the right end and is discharged from the left end. 4 transition slot mounting holes 1, bolts 21 can be used to image 3 The corresponding transition groove installation holes 12 are connected.

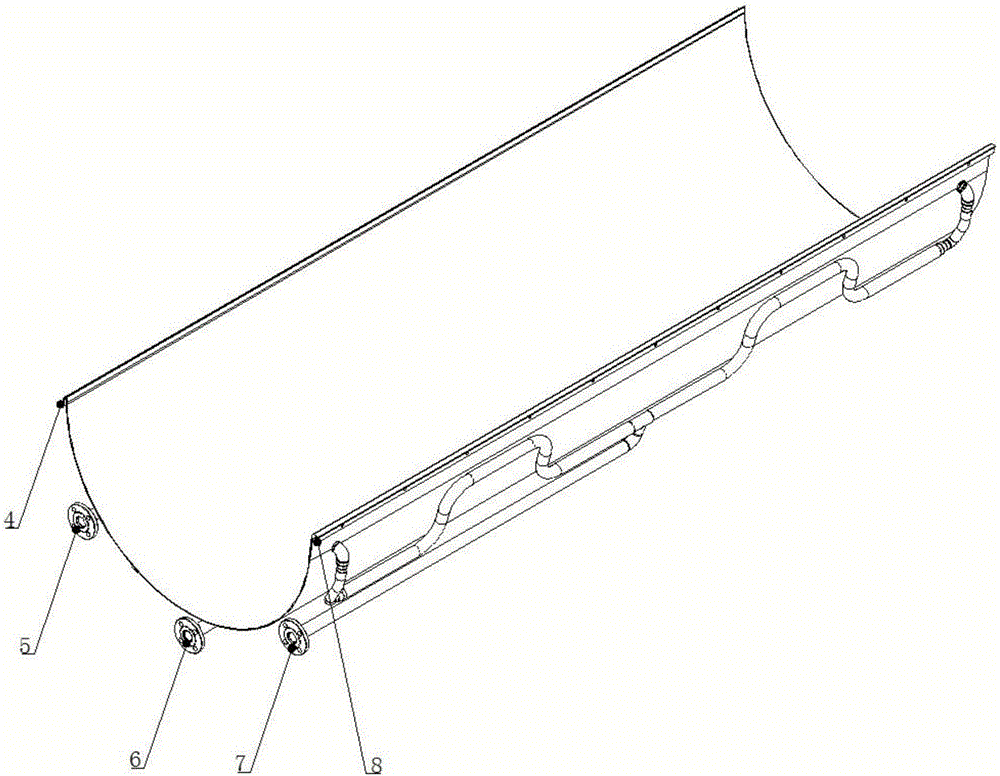

[0074] figure 2 5 and 7 in the flexible tank are the steam inlet, and 6 is the condensed water outlet. In the position shown in the figure, the left side is the dischar...

Embodiment 2

[0079] Ordinary rigid tanks usually only have one steam connection flange and one condensate water connection flange, one is connected to the external steam pipe, and the other is connected to the steam trap and the condensate recovery pipe. The inner groove plate that is in contact with the linen is a semicircular steel plate with an upward opening, and the arc-shaped steam chamber plate is superimposed on the back layer. The inner arc of the steam chamber plate and the outer arc surface of the inner groove plate form a steam channel. Opening gaps in the area where the steam chamber plate is overlapped by the next arc steam chamber plate can ensure the circulation of steam in each layer of steam chamber. The ends of the topmost steam chamber plates on both sides have an exhaust port respectively, through which the air inside the front steam chamber can be discharged from the steam.

[0080] And the present invention provides a kind of multi-chamber rigid ironing tank, such as...

Embodiment 3

[0090] see Figure 9 , an adjustable pressurization system of a trough ironing machine, including roller lifting cylinders C1, C2, electric proportional valves R1, R2, pressure regulating valve R3, solenoid valves Y1, Y2, Y3, and quick exhaust valve Q3. The compressed air is changed from the filter pressure reducing valve S1 to the 0.6MPa air source, connected to the solenoid valve group, including 3 solenoid valves Y1, Y2, Y3, Y1 controls the air path of the rod chamber of the cylinder, and can make the roller descend; Y2 Controlling the air path of the rodless chamber of the cylinder can make the roller rise; Y3 controls the air path of the rodless chamber of the cylinder C2 on the drive side of the roller, so that C2 can take in air and C1 can't.

[0091] Cylinders C1 and C2 are connected to the flanges on both sides of the roller through a bearing seat. The piston rod of the cylinder extends and retracts to make the roller rise and fall, and the rotation of the roller is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com