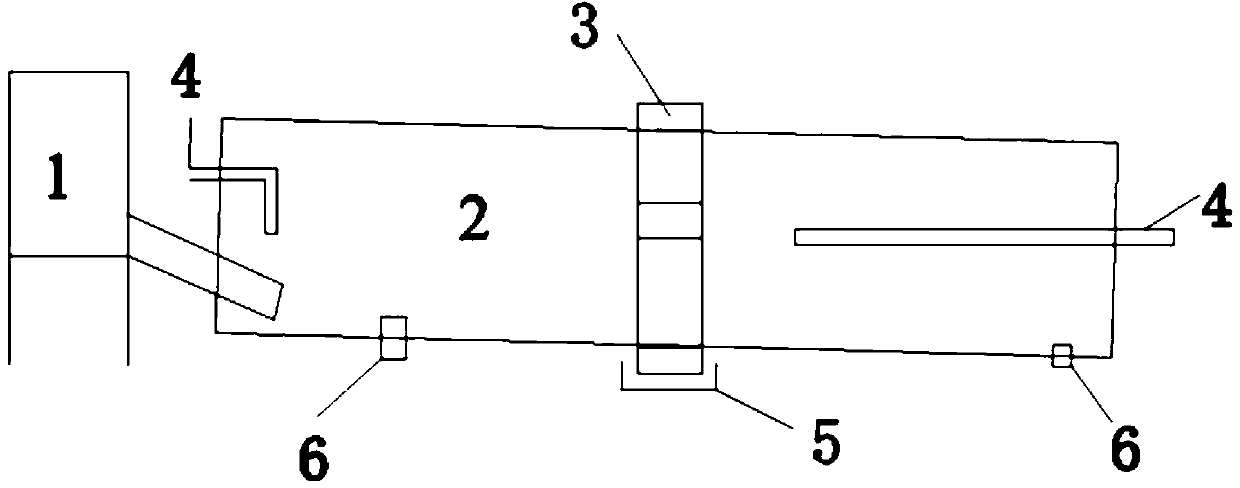

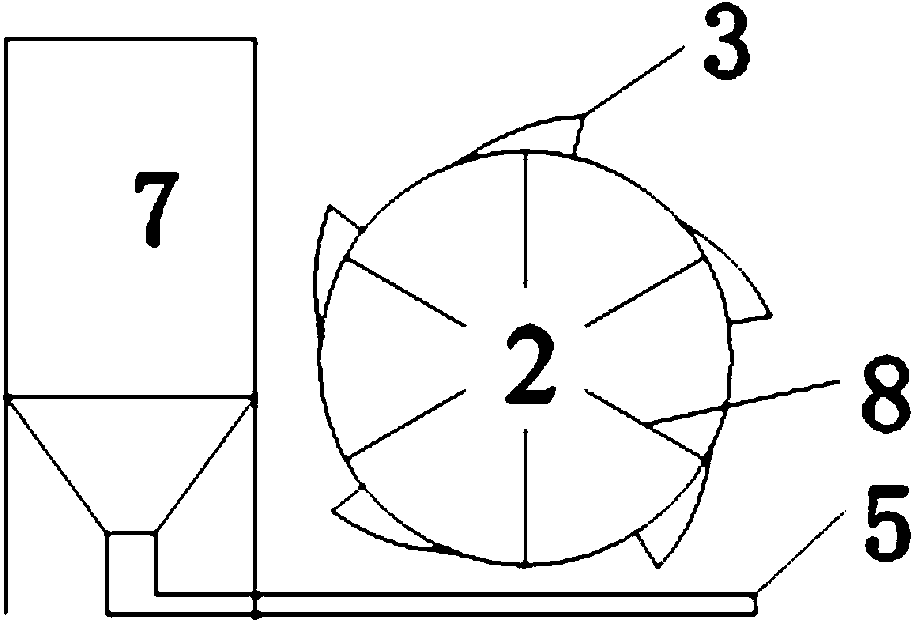

Gravity-type multiphase continuous stirring device for lightweight aggregate insulation products

A technology for thermal insulation products and lightweight aggregates, which is applied in cement mixing devices, clay preparation devices, and raw material supply devices for sale, etc. It can solve problems such as uneven mixing and unstable mixing quality, reduce maintenance costs, and ensure continuous stability. , the effect of reducing management pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Set the bulk density to 60kg / m 3 The expanded perlite, cement powder, ultra-fine silica powder, modified additive powder, water, emulsion, and modified additive liquid are added to the self-falling multi-phase material continuous stirring device of the present invention in steps, and the materials are fed from Adjust the time from material to discharge to 4 minutes, continuously stir 200L of expanded perlite, press the obtained stirred product into a 600mm×300mm×50mm lightweight aggregate board blank, and use a traditional stirring device to prepare the same number of lightweight aggregate boards Embryo. Compared with the product body obtained by the traditional stirring device, the color of the material stirred by the present invention is more uniform without any black spots. After curing and drying the two kinds of embryo bodies, they were tested for their compressive strength. The light aggregate board stirred by the present invention not only has a strength about ...

Embodiment 2

[0026] 100kg / m 3 The expanded perlite, cement, latex powder, and modified additive powder are added to the self-falling multi-phase material continuous stirring device of the present invention according to the steps, and the time from feeding to discharging of the material is adjusted to 4min, and the continuous stirring production On 30d, pack the mixed product - dry powder mortar according to the specification of 20L / bag, and use the traditional mixing device to prepare the same amount of products at the same time. After being placed for 1 day, the density of the dry powder mortar on the upper and lower parts of the packaging bag was measured, and it was found that the density fluctuation range of the density of the upper part of the packaging bag and the density of the lower part of the dry powder mortar stirred by the present invention is only 7%, while the density of the dry powder mortar stirred by the traditional device is only 7%. The fluctuation range is 15%. In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com