The Method of Top Height of Simply Supported Slab Bridge and Its Adjustable Height Composite Pad Stone Structure

A simply supported slab and bridge roof technology, which is applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as the inability to strengthen the connection between old and new pad stones, the limited placement of jacks, and the inability to dismantle jacking equipment, so as to reduce hinge cracking Possibility and degree of construction, high construction precision, and excellent economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

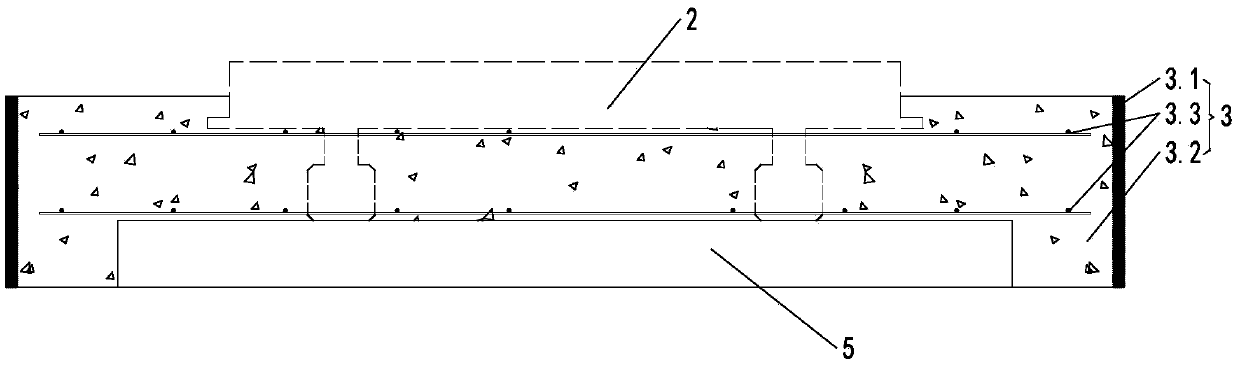

[0065] (1) Distance the bottom of bridge span 7 from the center line of pier 8 by L 1 =1.2~3m position horizontal bridge leveling, setting distance L 1 The purpose is to ensure that there is enough space for subsequent operations.

[0066] (2) Arrange a full-length distribution beam 9 along the leveling position along the bridge, and arrange a certain number of jacks 10 at a suitable position at the bottom of the distribution beam 9, and set up temporary jack support 11 under the jack 10; generally, ensure that L 1 If the distance is sufficient, the minimum distance between the distribution beam 9 and the pier 8 is not less than 60 cm at this time to ensure sufficient operating space for subsequent operations;

[0067] Preferably, in step (1) after the horizontal bridge is leveled, a leveling layer 12 is provided at the leveling place, and a distribution beam 9 is arranged under the leveling layer 12; the leveling layer 12 is a rectangular parallelepiped of 86*60*10 cm, so that furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com