A prefabricated reinforced concrete slab tire form and its construction method

A reinforced concrete and construction method technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of increasing construction procedures, unfavorable guarantee construction period, and prolonging construction time, so as to save labor, shorten construction period, and save The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

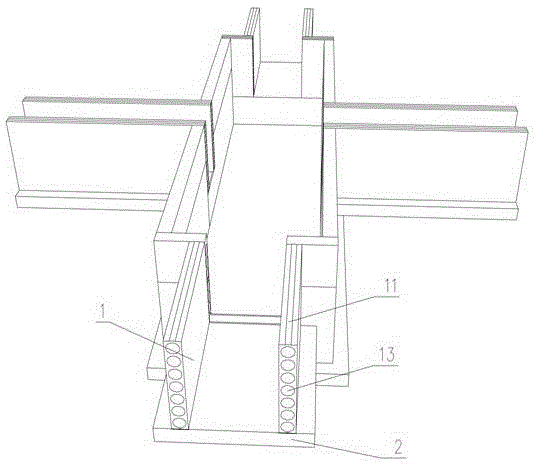

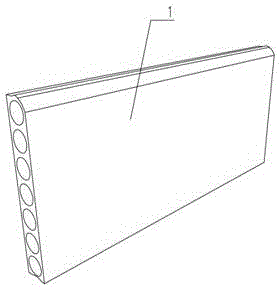

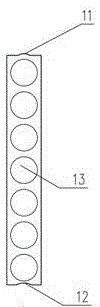

[0032] With reference to the above drawings, a prefabricated reinforced concrete slab tire mold includes a template plate body 1, the template plate body (1) has bosses on the upper surface and grooves on the lower surface, and is characterized in that the template plate body 1 is Rectangular prefabricated reinforced concrete formwork board structure. The upper surface of the formwork board body 1 is provided with a transverse arc-shaped boss 11, and the lower surface is provided with a transverse arc-shaped groove 12 that matches the transverse arc-shaped boss 11, that is, the template board. The upper surface of the body and the lower surface of the template board are superimposed and connected to form an arc-shaped concave-convex matching structure; this arc-shaped concave-convex matching structure prevents damage to the waterproof layer by the square concave-convex matching structure; the side of the template board 1 is provided with uniformly distributed Horizontal through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com