A multifunctional all-terrain walking hydraulic excavator

A hydraulic excavator, multi-functional technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the complex front wheel steering structure, terrain adaptability and poor grip reliability , poor production and processing technology, etc., to achieve the effect of achieving terrain passability and adaptability, improving operating scope and operating efficiency, and improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

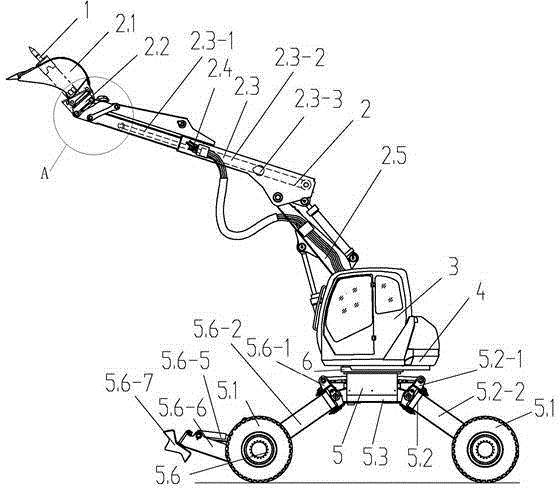

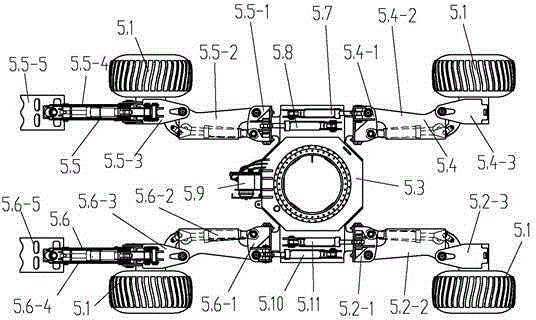

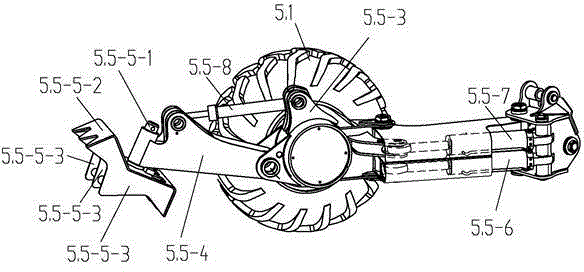

[0031] Such as figure 1 As shown, a multifunctional all-terrain walking hydraulic excavator includes a multifunctional working device 2 , a cab 3 , a slewing platform assembly 4 , a walking chassis 5 , and a slewing bearing 6 . The multifunctional working device 2 is integrally hinged and installed on the right front part of the rotary platform assembly 4; the cab 3 is fixed on the left half of the rotary platform assembly 4; the rotary platform assembly 4 is the upper cab 3, The carrying parts of the multifunctional working device 2 and the like are connected to the walking chassis 5 through the slewing bearing 6 .

[0032] Such as figure 1 As shown, the multifunctional working device 2 adopts the structure of "short curved boom + telescopic stick", including short curved boom 2.5, telescopic stick 2.3, bucket 2.1, connecting rod 2.6, rocker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com