Building formwork joint filling bar

A technology for building formwork and caulking strips, which is applied to buildings, building structures, and on-site preparation of building components, can solve problems such as easy slurry leakage, and achieve the effects of low cost, less consumables, and obvious shielding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

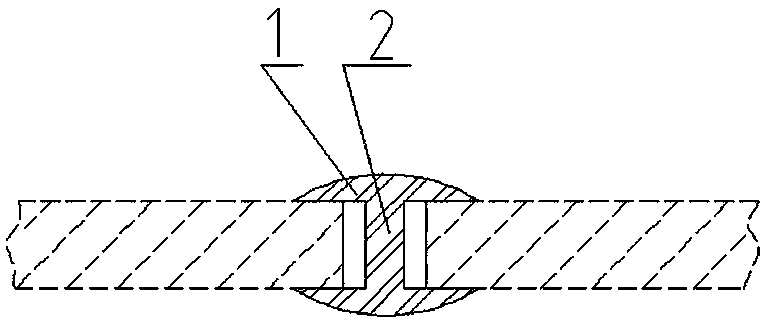

Embodiment 1

[0021] This embodiment is applied to the occasion of butt jointing of building formwork, the length of the building formwork used is 1800mm, the thickness is 10mm, and the expansion joints reserved between the building formworks are 2mm-3mm wide. The expansion joints of this structure are butt joints, and the cross-section is selected as figure 1 The I-shaped caulking strip shown is 1800mm long, 18mm wide on the horizontal side, 1.5mm thick in the middle of the cross-section of the horizontal side 1, and 10mm high on the vertical side 2. When the building formwork on one side is paved in place, then the open angular groove on one side of the caulking strip is matched with the already in place building formwork, and the opening angular groove on the other side of the caulking strip is inserted into the building formwork to be paved later. A seamless joint is formed between adjacent building formwork. In this embodiment, the width of the horizontal side 1 is much larger than th...

Embodiment 2

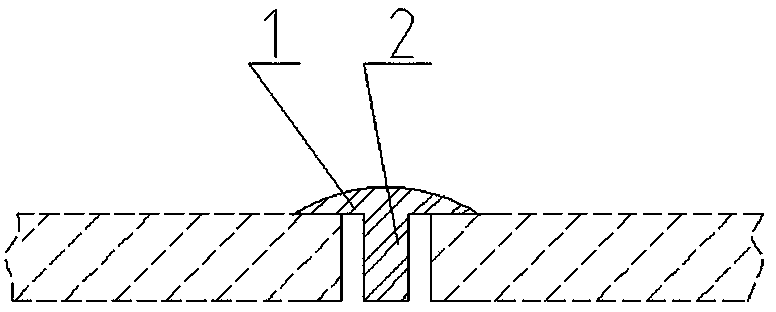

[0023] This embodiment is a cross section such as figure 2 The application of the T-shaped sealing strip shown is the same as that in embodiment 1, except that the joint filling strip is inserted into the reserved expansion joint after the adjacent templates are paved together. In this embodiment, the paved building formwork is 1800mm long and 18mm thick, with expansion joints of 2mm to 3mm reserved, and the matching caulking strips are cut according to 1800mm. , the height of the vertical side 2 is 18mm. The caulk ratio for this structure figure 1 The caulking strip with I-shaped cross-section shown is more convenient to install and has a similar leak-proof effect. The disadvantage is that it is easy to move longitudinally, but it does not affect the sealing.

Embodiment 3

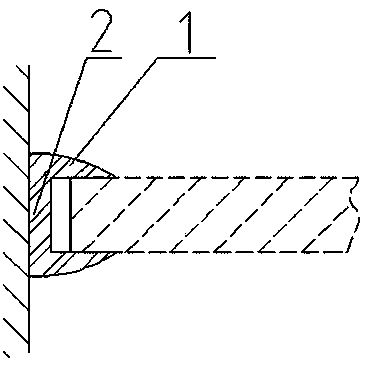

[0025] This embodiment is a cross section such as image 3 For the 匚-shaped caulking strip shown, the caulking strip of this structure is set on the outer edge of the initial or last building formwork. image 3 The caulk shown is figure 1 The cross-section shown is a deformed body of the I-shaped caulking strip, and the upper and lower horizontal sides 1 on one side of the vertical side 2 are removed, and the rest is a U-shaped caulking strip. The structural caulking strip is set on the edge of the matching building formwork, and the gap can be eliminated by adjusting the matching position. The transverse edge 1 in this embodiment is 7mm wide, and all the other dimensions are the same as Embodiment 1, and the actual use effect is also similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com