Deslagging device and rotary drilling rig

A technology of rotary drilling rig and slag discharge pipe, which is applied in earthwork drilling, wellbore/well parts, flushing wellbore, etc. It can solve the problems of reducing the crushing efficiency of primary rock or soil layer, easy accumulation, and accelerated tooth wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Below in conjunction with accompanying drawing, each preferred embodiment of the present invention is described further:

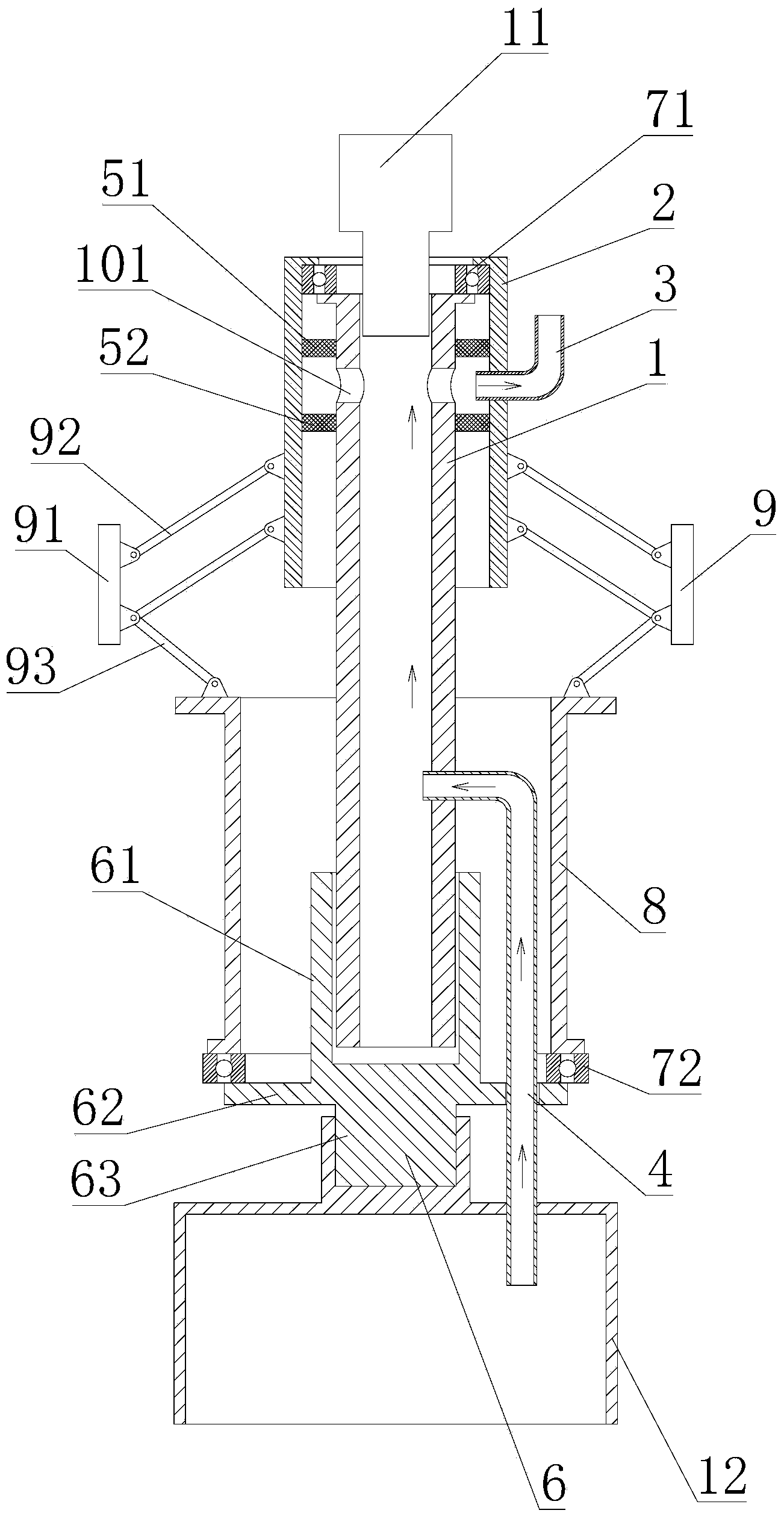

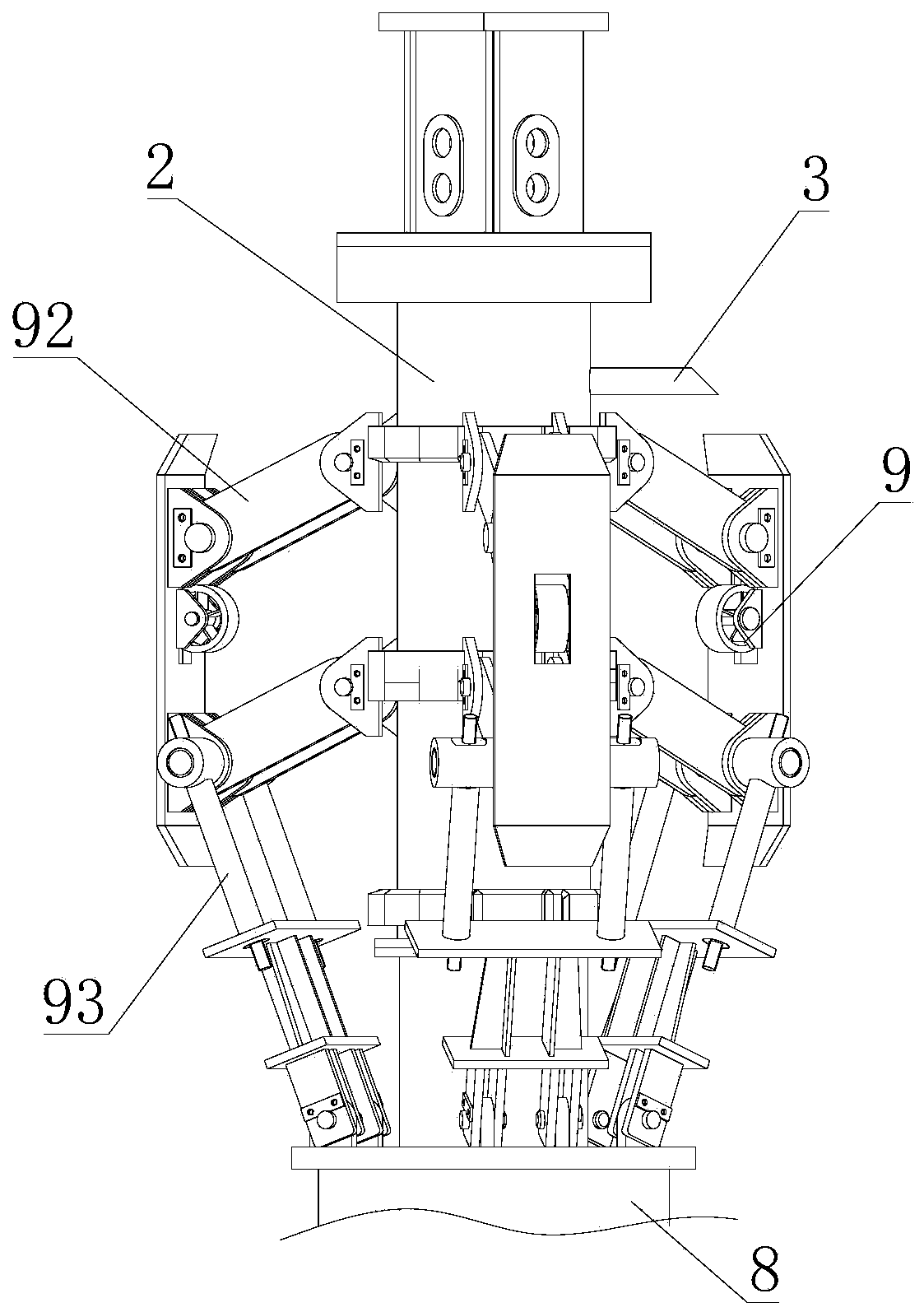

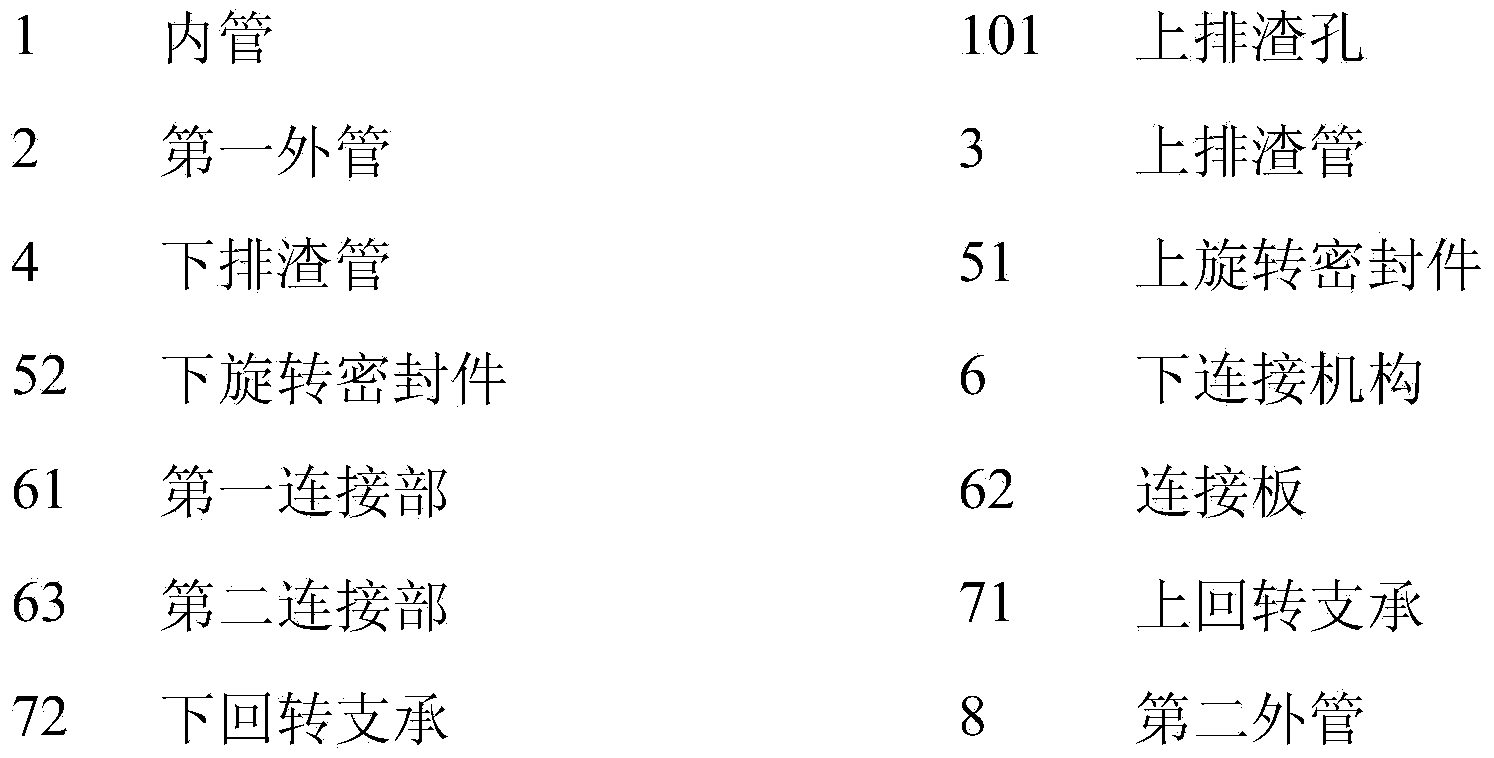

[0024] See figure 1 , the figure shows the structure of the slag discharge device provided by the embodiment of the present invention. In order to more clearly show the connection relationship and working principle of the components, the figure also shows the drill pipe 11 and the drill tool 12 . The slag discharge device provided in this embodiment is used for rotary drilling rigs, including: an inner pipe 1, a first outer pipe 2, an upper slag discharge pipe 3, a lower slag discharge pipe 4 and a slag suction pump (not shown in the figure), wherein ,

[0025] The first outer tube 2 is sleeved outside the inner tube 1, and the inner tube 1 is driven to rotate by the drill rod 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com