Ultrasonic non-destructive real-time monitoring method for surrounding rock hazards in underground engineering

An underground engineering and real-time monitoring technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as unsatisfactory monitoring and early warning effects, high requirements for installation quality, and complicated post-analysis of monitoring data. The effect of saving manpower, authentic and reliable data, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

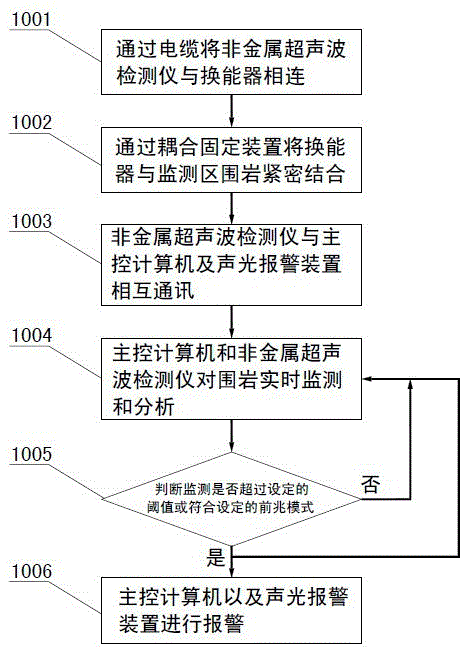

[0032] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

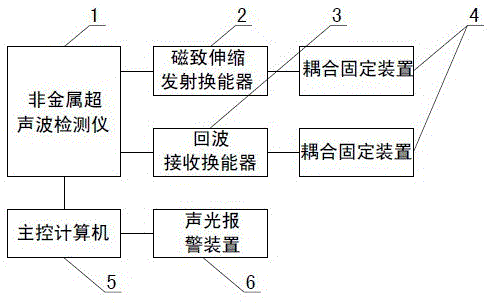

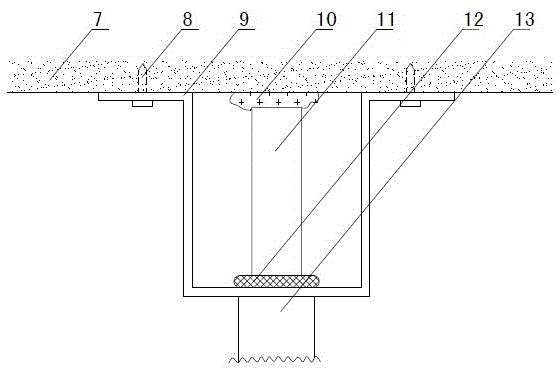

[0033] The non-drilling ultrasonic non-destructive real-time monitoring method for surrounding rock disasters in underground engineering of the present invention adopts the ultrasonic pulse reflection echo method to monitor the inside of surrounding rock. The ultrasonic pulse reflection echo method is a method of detecting the interior of the surrounding rock by observing the reflected wave from the internal defect by transmitting the pulse wave to the interior of the surrounding rock by the ultrasonic probe. Such as figure 1 As shown, it includes a non-metal ultrasonic detector 1 , a magnetostrictive transmitting transducer 2 , an echo receiving transducer 3 , a coupling fixing device 4 , a main control computer 5 and an audible and visual alarm device 6 . The magnetostrictive transmitting transducer 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com