Loop Fault Monitoring System for Multiple Bus Sections in DC System

A DC system and fault monitoring technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of lack of search tools or instruments, ineffective pairing, etc., to enhance anti-interference ability, ensure simultaneity, high The effect of redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

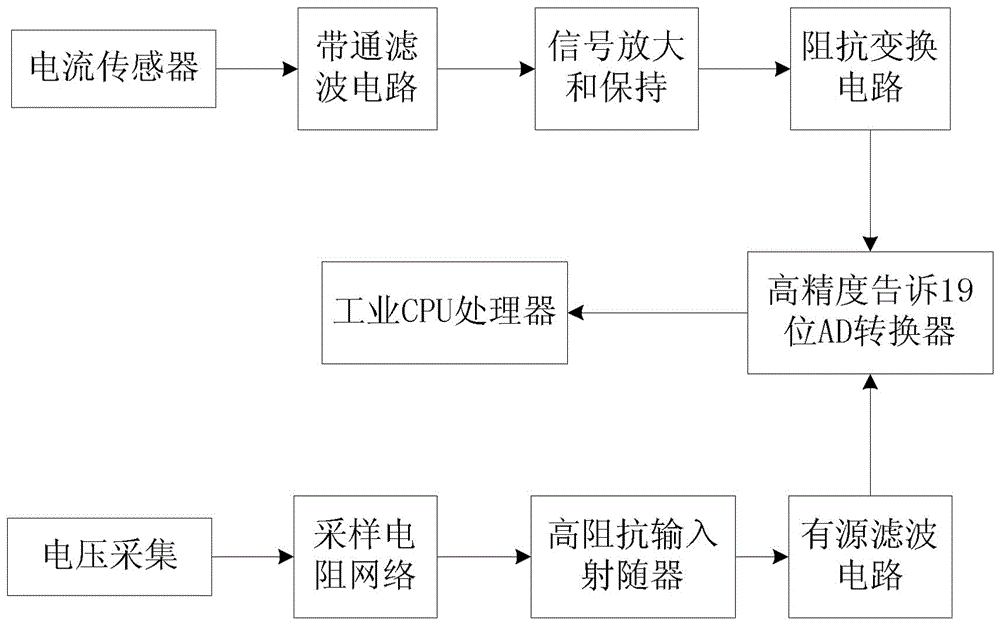

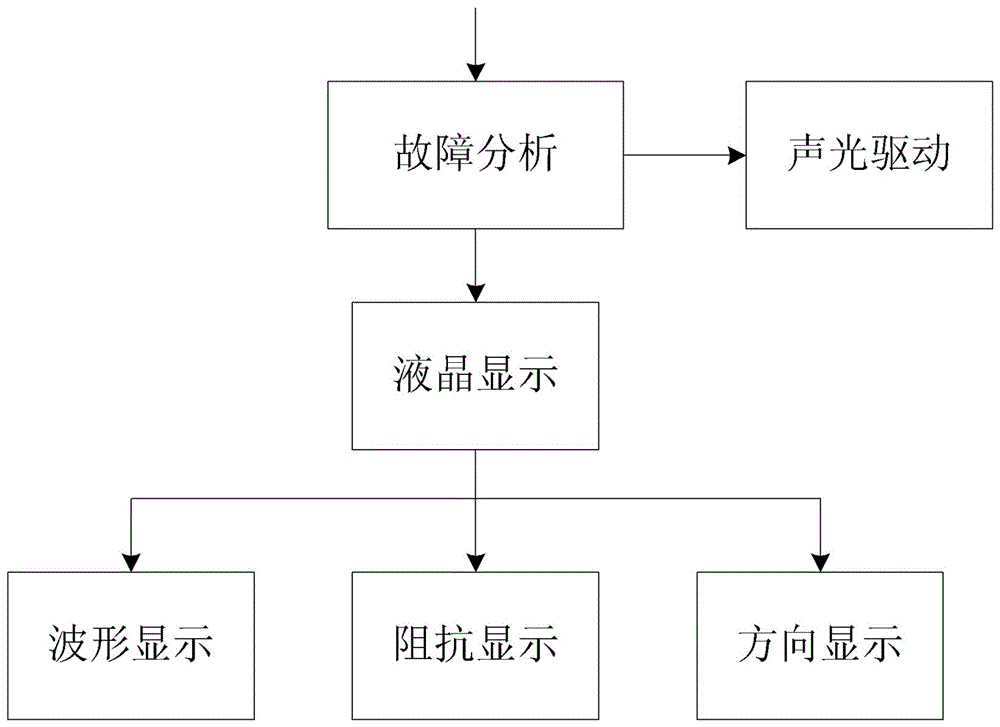

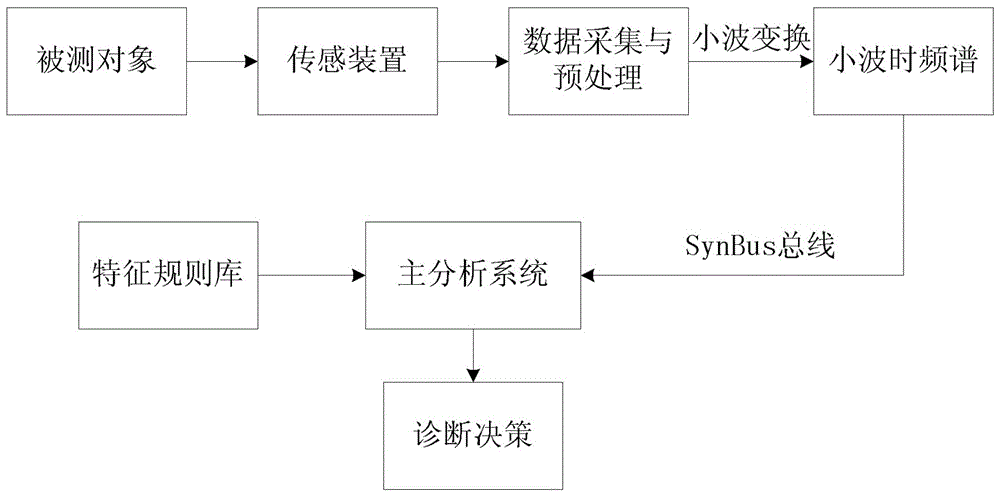

[0028] Example: see Figure 1 to Figure 4 , a DC system multi-bus section loop fault monitoring system, including a signal acquisition and preprocessing module SCM, a signal analysis and processing module SAM and a loop fault alarm module LWM,

[0029] ①Signal acquisition and preprocessing module SCM: responsible for collecting the ground voltage of the two busbars, including high-precision DC leakage current sensor, band-pass filter circuit, signal amplification device, impedance conversion circuit, high-precision AD converter, CPU processor, Active filter circuit, high-impedance input emitter follower and active filter circuit; among them: the high-precision AD converter is a 16-bit ADS1110 chip with differential input and 16-bit resolution, packaged as a small SOT23-6, on-chip 2.048 The reference voltage of V provides a differential voltage in the range of ±2.048V. It uses a compatible I2C serial interface and operates from a single power supply of 2.7 to 5.5V. The on-chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com