A kind of preparation method of superhydrophobic self-cleaning resin lens

A resin lens, self-cleaning technology, applied in the field of optical lenses, to achieve the effect of prolonging the service life and preventing fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

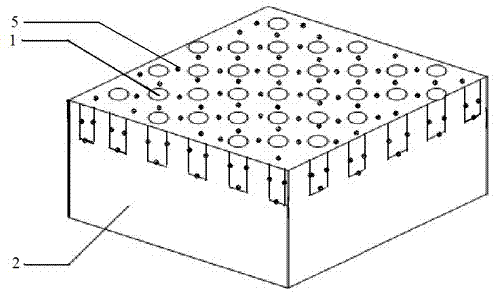

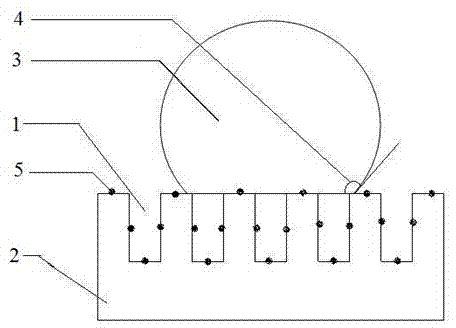

[0021] The pore diameter is 8um, the pore spacing is 14um, the pore depth is 43um, the glycerol monostearate particle size is 115nm, and the contact angle is 145 degrees.

Embodiment 2

[0023] The pore diameter is 10um, the pore spacing is 17um, the pore depth is 40um, the glyceryl monostearate particle is 100nm, and the contact angle is 140 degrees.

Embodiment 3

[0025] The pore diameter is 13um, the pore spacing is 20um, the pore depth is 45um, the glycerol monostearate particle size is 120nm, and the contact angle is 134 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com