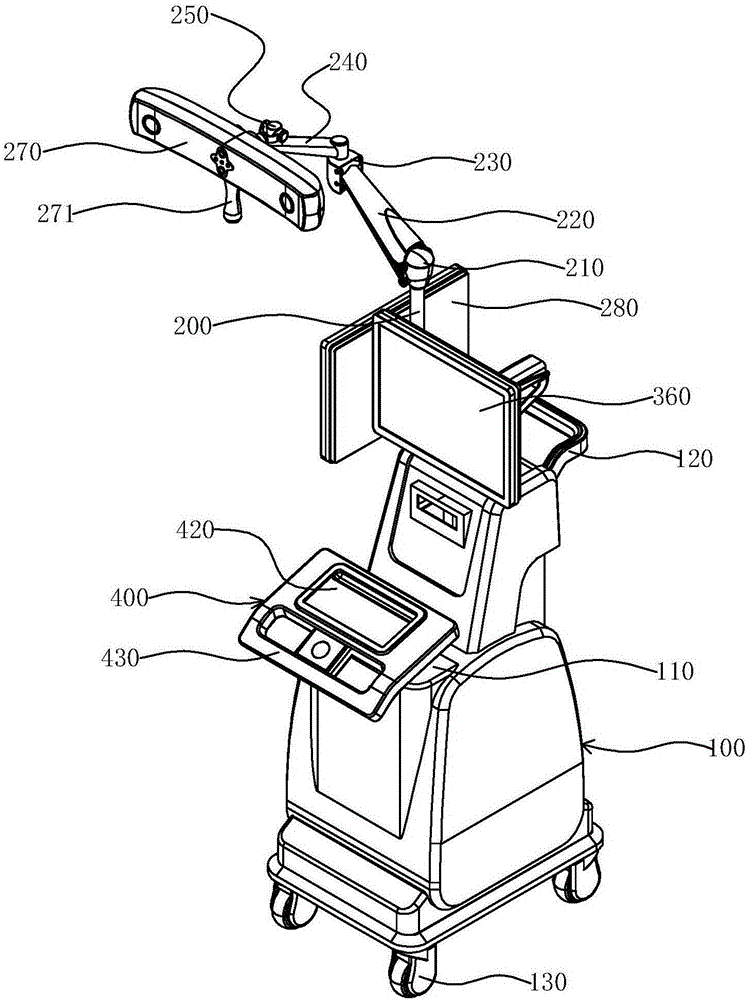

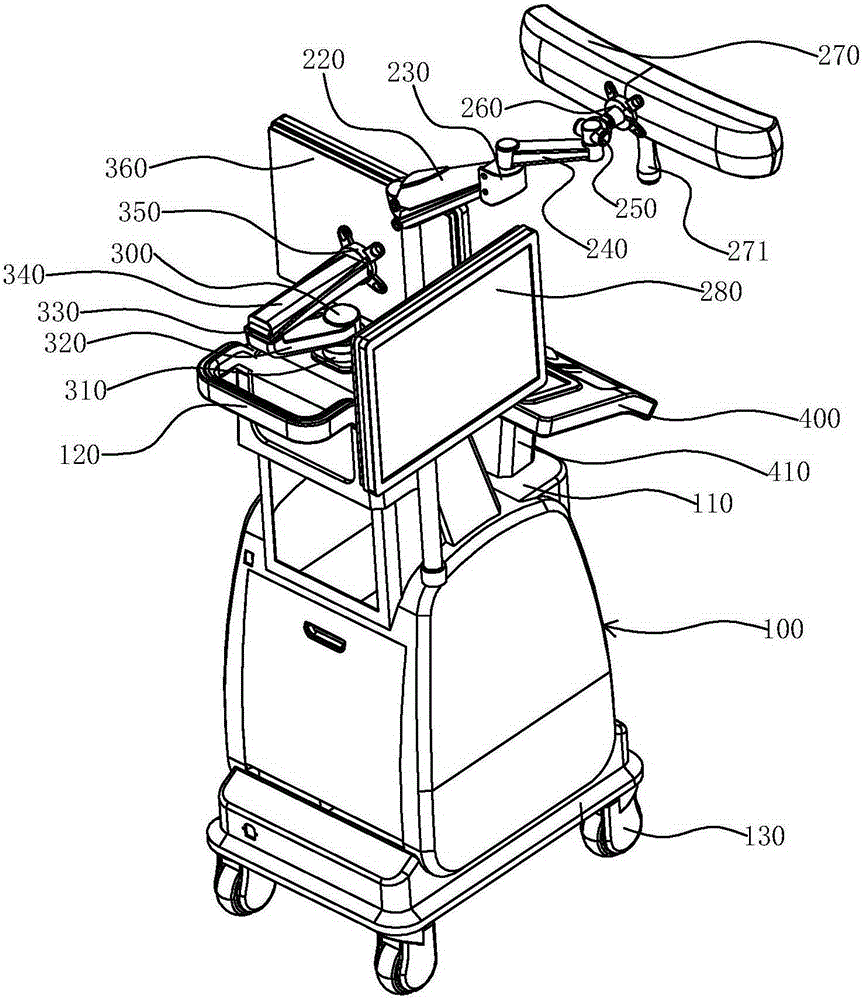

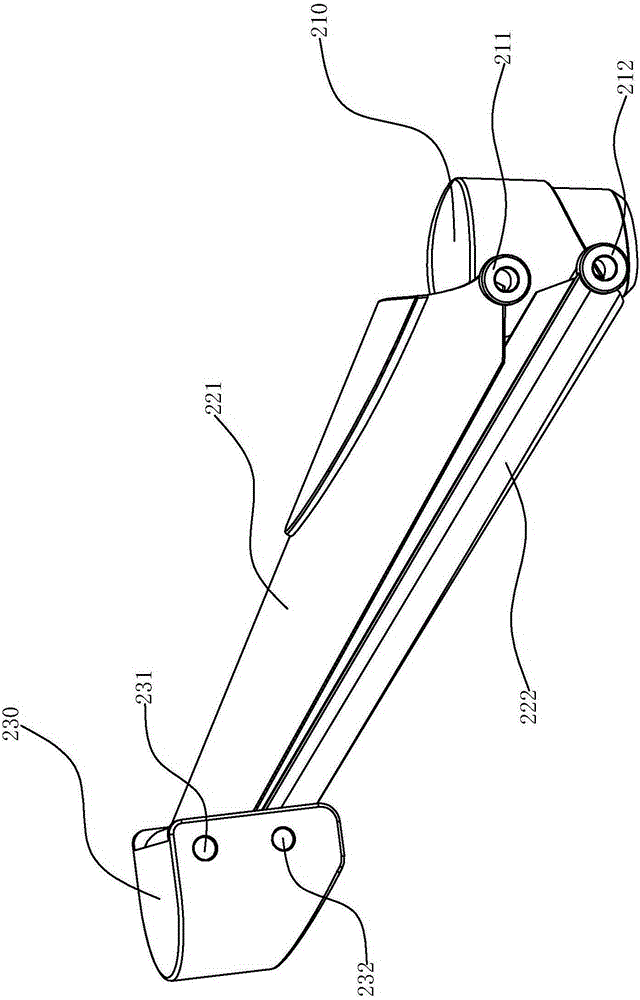

Orthopedic navigation device and preparation method thereof

A navigation device, orthopedic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]Add Al powder, Sn powder, Zr powder, Mo powder, V powder, Mn powder, Cr powder, Si powder, and Ti powder according to the composition and mass percentage of Example 1 in Table 1 and mix evenly to form a Ti electrode. Then the Ti electrode is vacuum smelted in a vacuum consumable electrode electric arc furnace with a vacuum degree of 2Pa, an arc voltage of 27V, and an arc current of 4780A. After melting into a titanium alloy ingot, the vacuum degree is 2Pa, and the arc voltage is 38V. Melting is carried out in a vacuum consumable electrode coagulation furnace with an arc current of 13690A. At the same time, the mold was heated to 265°C, and the molten metal was poured at a temperature of 1260°C and a centrifugal speed of 296r / min. After pouring, it was cooled for 3 hours under a vacuum of 3Pa to obtain the first support. a rod blank and a second support rod blank. Afterwards, the first support rod blank and the second support rod blank are subjected to finishing, grindin...

Embodiment 2

[0055] Add Al powder, Sn powder, Zr powder, Mo powder, V powder, Mn powder, Cr powder, Si powder, Ti powder according to the composition and mass percentage of Example 2 in Table 1 and mix evenly, and press to form a Ti electrode. Then the Ti electrode is vacuum smelted in a vacuum consumable electrode electric arc furnace with a vacuum degree of 3Pa, an arc voltage of 26V, and an arc current of 4850A. After melting into a titanium alloy ingot, the vacuum degree is 3Pa, and the arc voltage is 42V. Melting is carried out in a vacuum consumable electrode shell furnace with an arc current of 15300A. At the same time, the mold was heated to 250°C, and the molten metal was poured at a temperature of 1380°C and a centrifugal speed of 299r / min. After pouring, it was cooled for 4 hours under a vacuum of 3Pa to obtain the first support. a rod blank and a second support rod blank. Afterwards, the first support rod blank and the second support rod blank are subjected to finishing, grind...

Embodiment 3

[0057] Add Al powder, Sn powder, Zr powder, Mo powder, V powder, Mn powder, Cr powder, Si powder, Ti powder according to the composition and mass percentage of Example 3 in Table 1 and mix evenly, and press to form a Ti electrode. Then the Ti electrode is vacuum smelted in a vacuum consumable electrode electric arc furnace with a vacuum degree of 1Pa, an arc voltage of 29V, and an arc current of 4890A. After melting into a titanium alloy ingot, the vacuum degree is 3Pa, and the arc voltage is 42V. Melting is carried out in a vacuum consumable electrode coagulation furnace with an arc current of 14900A. At the same time, the mold was heated to 270°C, and the molten metal was poured at a temperature of 1470°C and a centrifugal speed of 306r / min. After pouring, it was cooled for 5 hours under a vacuum of 2Pa to obtain the first support. A rod blank and a second support rod blank. Afterwards, the first support rod blank and the second support rod blank are subjected to finishing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com