Vibrating device capable of preventing material sticking

A technology of vibrating devices and materials, which can be applied in the fields of fluids using vibration, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

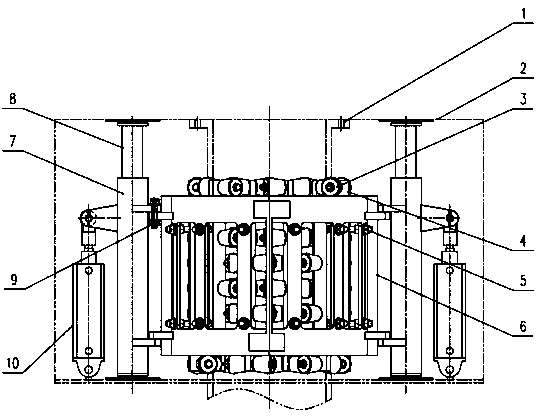

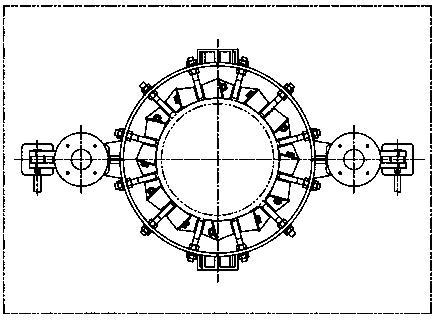

[0030] Such as figure 1 with figure 2 As shown, the material cylinder 1 is fixed on the support platform 2, and the middle of the material cylinder 1 is equipped with an agitator for mixing materials (the figure is omitted), and the material is continuously added from the upper entrance of the material cylinder 1, and the material Receiving equipment (not shown).

[0031] Fix the roller part 3 on the roller placement block 4, and then connect the roller placement block 4 to the roller assembly support frame 6 with the adjustment fastener 5; The material of the roller is nylon.

[0032] After the sliding sleeve 7 is sleeved on the fixed shaft rail 8, the roller assembly support frame 6 and the sliding sleeve 7 are connected by connecting fasteners 9. The four-piece roller assembly supporting frame 6 is combined around the material cylinder 1 and fixed in the circumferential direction; the radial position of the roller member 3 is adjusted by adjusting the fastener 5, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com