Gluing device

The technology of a gluing device and a glue gun is applied to devices and coatings for applying liquid to the surface, which can solve the problems of low gluing work efficiency, non-standard gluing, waste of glue liquid, etc., and achieves simple and reasonable structure. Easy and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

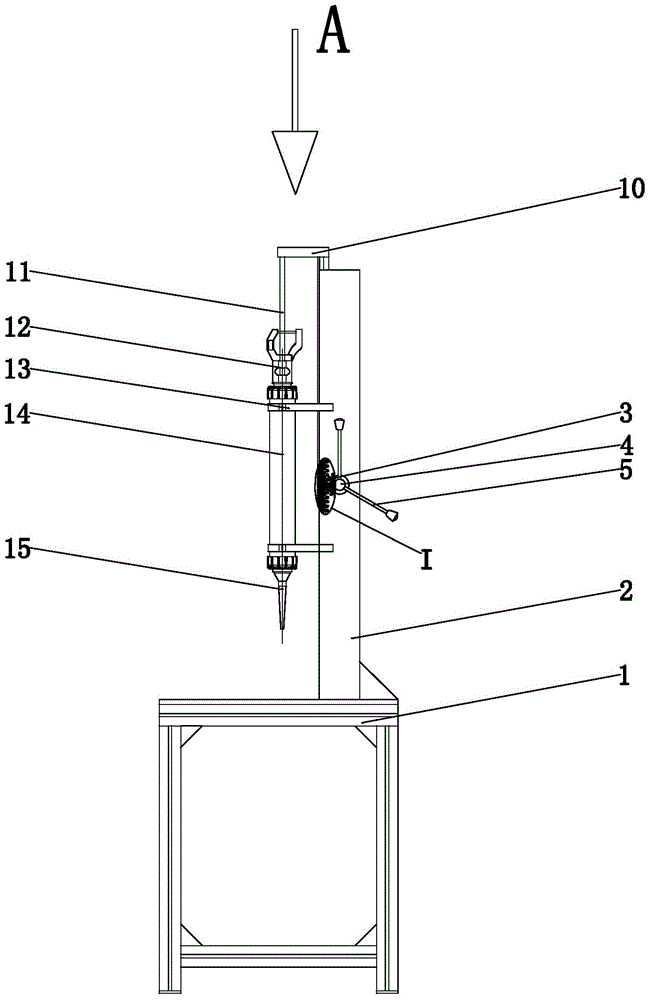

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

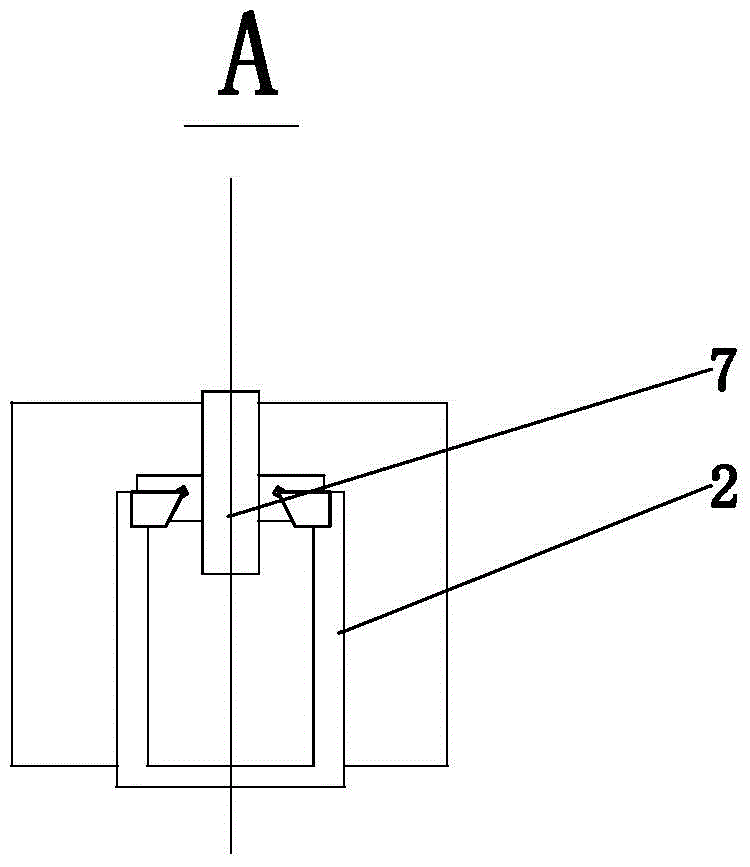

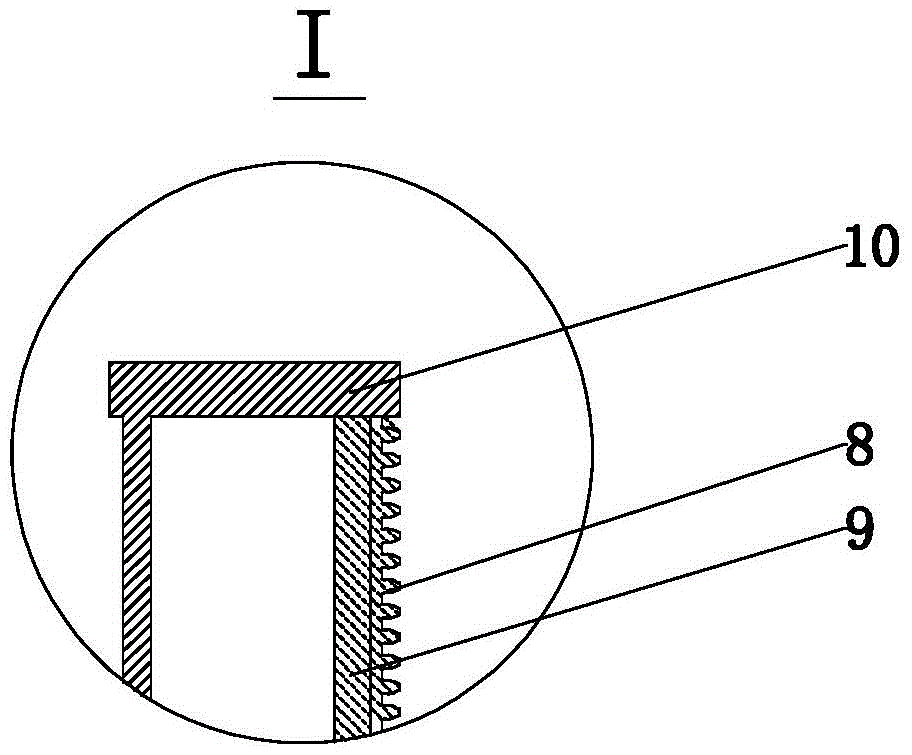

[0016] like Figure 1~4 Shown, the present invention mainly comprises frame 1, and fixed sliding guide rail 2 is fixed on the frame 1, slide plate 7 is slidably installed in slide guide rail 2, and connecting rod 9 is fixed on the slide plate 7, and connecting rod 9 is provided with manual transmission mechanism.

[0017] The manual transmission mechanism includes a rack 8 fixed on the connecting rod 9 and a transmission gear 3 arranged on the transmission shaft 4 , the rack 8 is meshed with the transmission gear 3 for transmission. The transmission shaft 4 is installed on the sliding guide rail 2 through the bearings 6 at both ends. One end of the transmission shaft 4 is connected to the handle 5, and the transmission shaft 4 can be manually pushed to rotate through the handle 5, thereby driving the transmission gear 3 arranged on the transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com