Method for increasing ITO (indium tin oxide) conductive film surface infrared band light transmittance

A conductive film, infrared band technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of weakening the ability to collect charges, increasing the resistance of ITO conductive films, uneven micro-nano structure, etc., to reduce uneven energy distribution. , The effect of improving power generation efficiency and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for improving the infrared band light transmittance on the surface of an ITO conductive film, comprising the following steps:

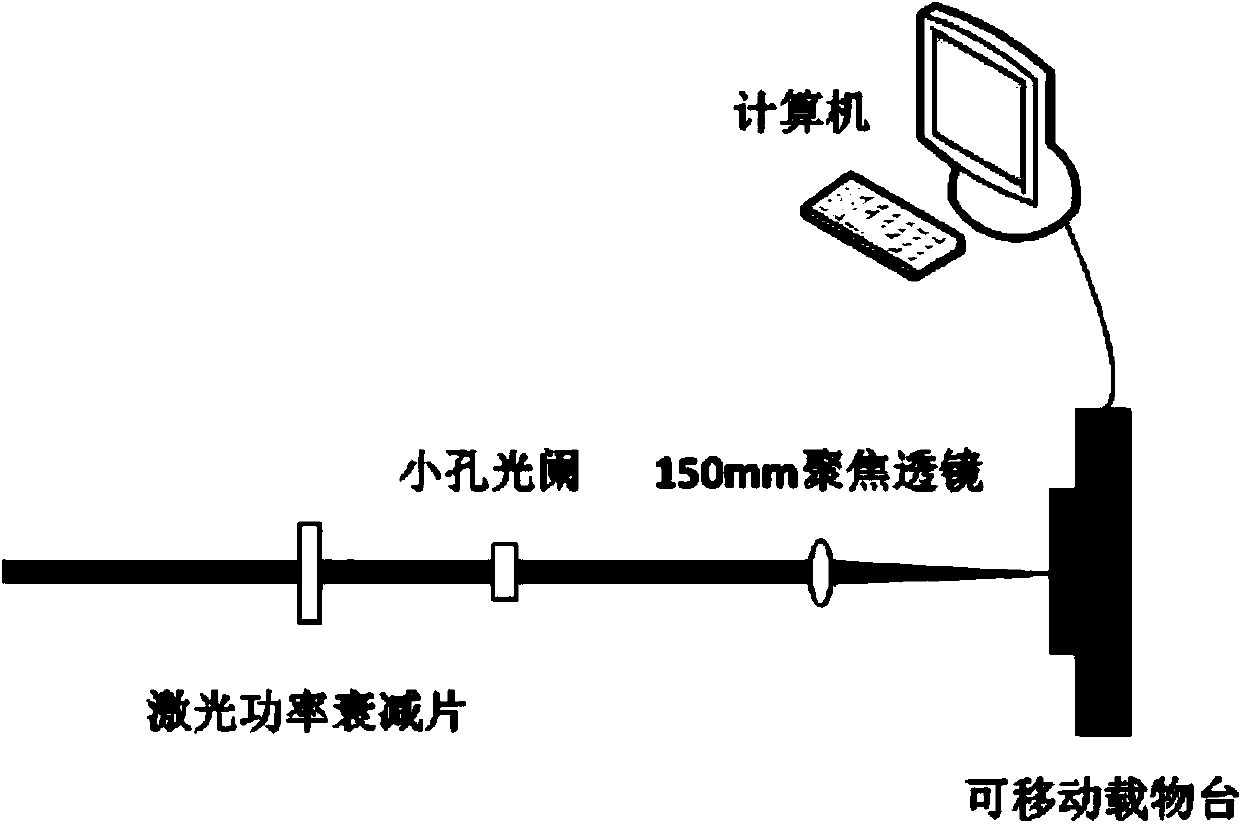

[0020] 1) First, adjust the picosecond laser output laser wavelength to 1064nm, repetition frequency 1KHz, pulse width 10ps, and adjust the laser power attenuator to stabilize the laser power at 25mw, such as figure 1 shown;

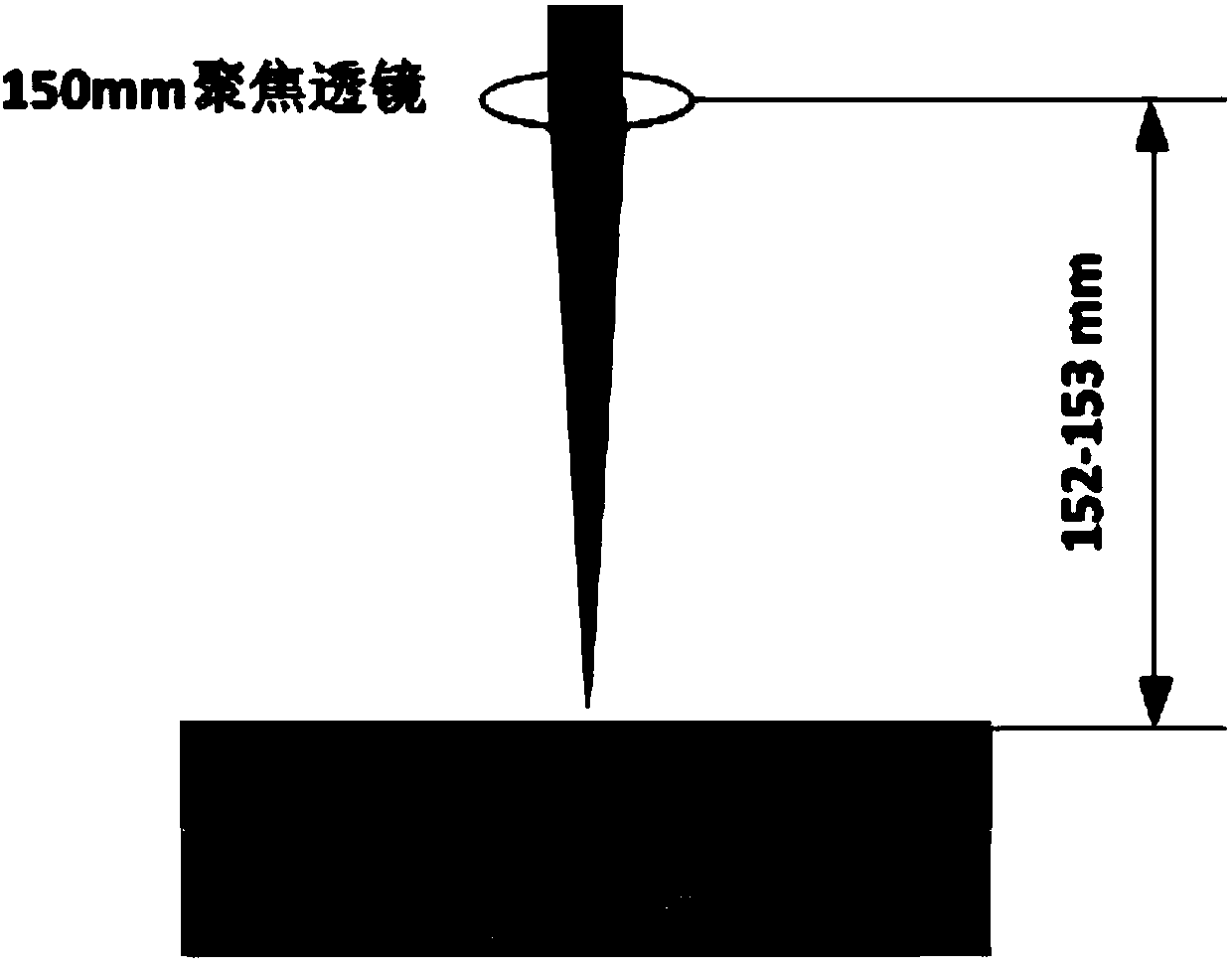

[0021] 2) Secondly, select a focusing lens with a focal length of 150mm in the optical path to focus the light beam, install a small aperture diaphragm in front of the focusing lens, and adjust the size of the aperture of the small aperture diaphragm so that the distance along the optical path is 2mm away from the focal point The spot size is 40μm, such as figure 1 shown;

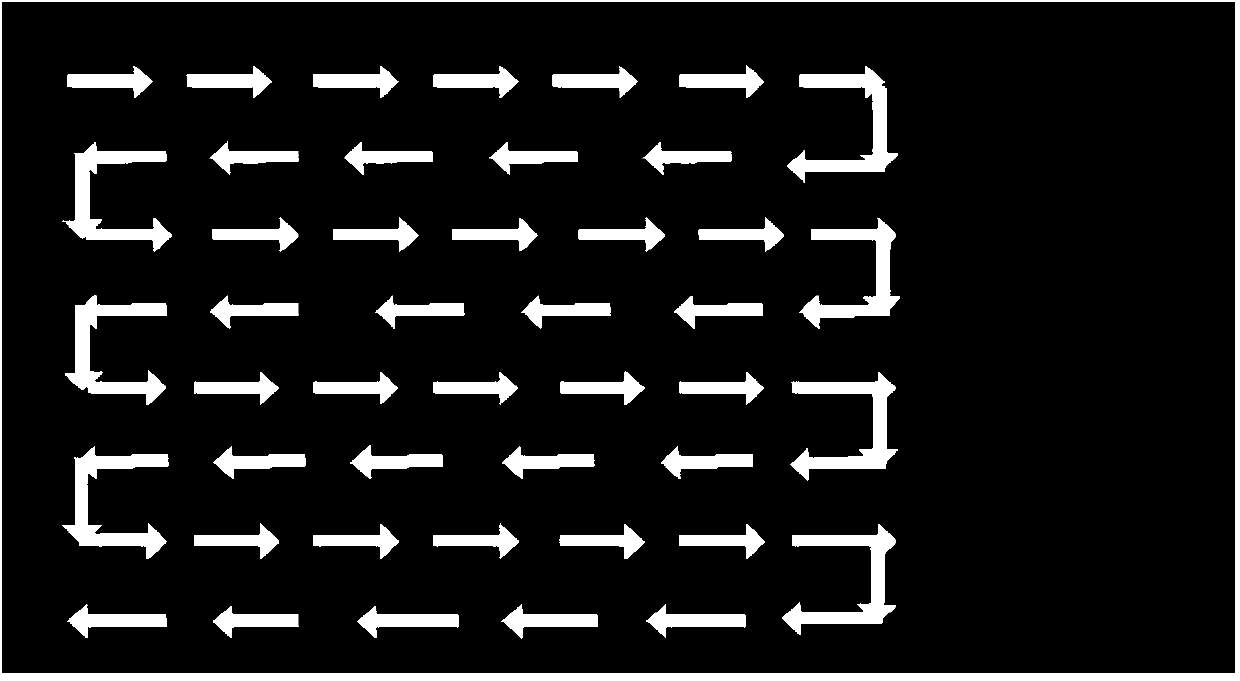

[0022] 3) Finally, use the adjusted picosecond laser to irradiate the ITO conductive film on the movable stage, and the movable stage moves in the horizontal direction at a speed of 2mm / s. When the laser spot reaches the horizontal direction...

Embodiment 2

[0024] A method for improving the infrared band light transmittance on the surface of an ITO conductive film, comprising the following steps:

[0025] 1) First, adjust the picosecond laser output laser wavelength to 1064nm, repetition frequency 1KHz, pulse width 10ps, adjust the laser power attenuator to stabilize the laser power at 22mw, such as figure 1 shown;

[0026] 2) Secondly, select a focusing lens with a focal length of 150mm in the optical path to focus the light beam, install a small aperture diaphragm in front of the focusing lens, and adjust the size of the aperture of the small aperture diaphragm so that the distance along the optical path is 2mm away from the focal point The spot size is 45μm, such as figure 1 shown;

[0027] 3) Finally, use the adjusted picosecond laser to irradiate the ITO conductive film on the movable stage, and the movable stage moves in the horizontal direction at a speed of 4mm / s. When the laser spot reaches the horizontal direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com