Injecting vacuum molding machine direct drive motor driving and plasticizing apparatus

A direct drive motor and molding machine technology, applied in the field of plastic machinery, can solve the problems of energy consumption, high energy consumption, hydraulic oil leakage, etc., and achieve the effect of convenient and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

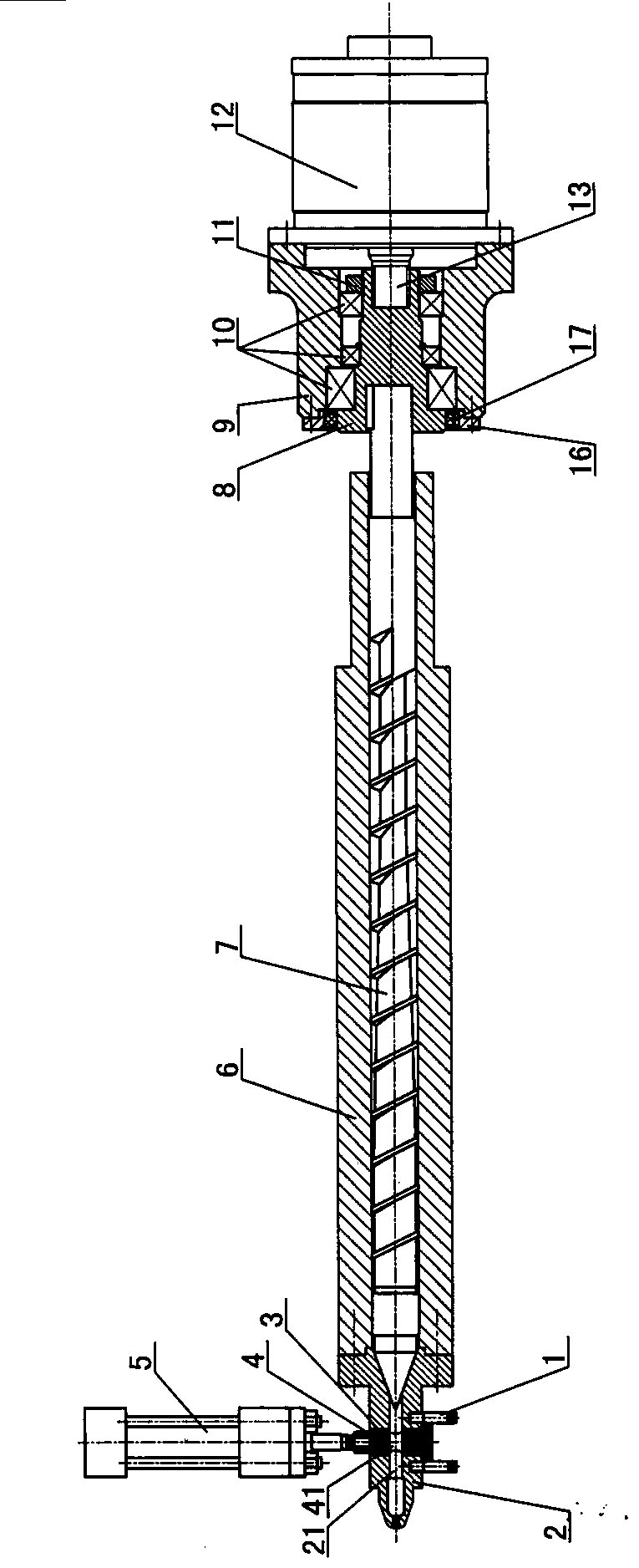

[0008] The invention relates to a plasticizing device driven by a direct drive motor of an injection blow molding machine, such as figure 1 As shown, it includes the plasticizing barrel 6 of the injection blow molding machine. The nozzle seat 2 is installed on the head of the plasticizing barrel. There is a nozzle hole 21 in the nozzle seat 2. A shut-off mechanism is set on the nozzle seat 2. In the plasticizing barrel, Screw rod 7 is set, and screw rod 7 is driven by direct drive device, and described direct drive device comprises the direct drive motor 12 that is installed on the back plate 9 of shooting platform, and coupling 8 is installed in the back plate 9 of shooting platform, and the direct drive motor 12 The output shaft 13 is connected with the tail end of the coupling 8, and the front end of the coupling 8 is connected with the screw rod 7. The shut-off mechanism includes a pin 4 installed in the nozzle seat 2, and a through hole 41 is formed in the pin 4 , the thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap