High-strength bonding resin for aluminum-plastic composite plate

A technology of aluminum-plastic composite board and bonding resin, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of low adhesion, achieve high adhesion, and be easy to store and transport Effect

Active Publication Date: 2014-04-23

SHANGHAI BANZAN MACROMOLECULE MATERIAL

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the adhesion is not high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

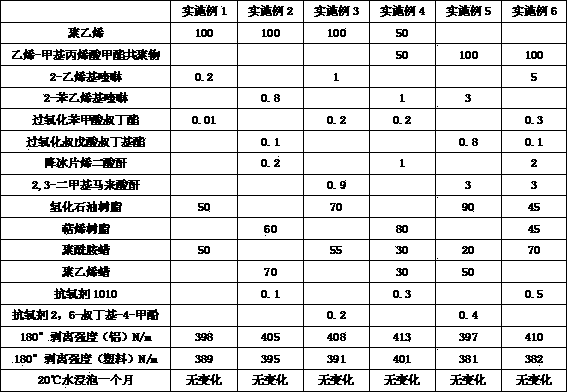

Embodiment 1-6

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides high-strength bonding resin for an aluminum-plastic composite plate. The high-strength bonding resin is composed of polyolefin, vinyl quinoline, an initiator, tackifying resin and a viscosity modifier. A preparation method of the high-strength bonding resin for the aluminum-plastic composite plate comprises the following steps: heating and agitating by using a reaction kettle; firstly, heating at 120-200 DEG C to fuse polyolefin resin; then adding the initiator and the vinyl quinoline or other grafting compounds; uniformly mixing to obtain a grafting copolymer; further adding the tackifying resin and an antioxidant and fusing and agitating uniformly; and finally, adding the viscosity modifier and fusing uniformly, and discharging to obtain the bonding resin.

Description

[0001] technical field [0002] The invention belongs to the technical field of adhesives, and in particular relates to a special adhesive resin for aluminum-plastic composite panels and a preparation method thereof. [0003] Background technique [0004] Aluminum-plastic panels, also known as aluminum-plastic composite panels, were first developed and produced by ALUDINGEN in Germany in the 1960s, and then improved by FORKEN and ALOCA. , After the 1990s, the production quality gradually stabilized and reached a higher level. After more than 30 years of development, the technology has been relatively perfect. At present, the larger foreign production companies include: Alusingen Company of Germany, Reynolds Group Company of the United States, and Mitsubishi Corporation of Japan. It entered the Chinese mainland in the late 1980s and early 1990s. The aluminum-plastic panel industry has achieved extraordinary development in China in just 10 years. In just a few years, my coun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J123/06C09J123/08C09J11/06C09J11/08

Inventor 毕宏海储江顺陈明波程安顺程启山

Owner SHANGHAI BANZAN MACROMOLECULE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com