Energy-saving environment-friendly pickling equipment

A kind of pickling equipment, energy saving and environmental protection technology, applied in the field of energy saving and environmental protection pickling equipment, can solve the problems of high operating cost, increased waste acid output, low cost, etc., and achieve the goals of reducing energy consumption, improving production efficiency, and reducing treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

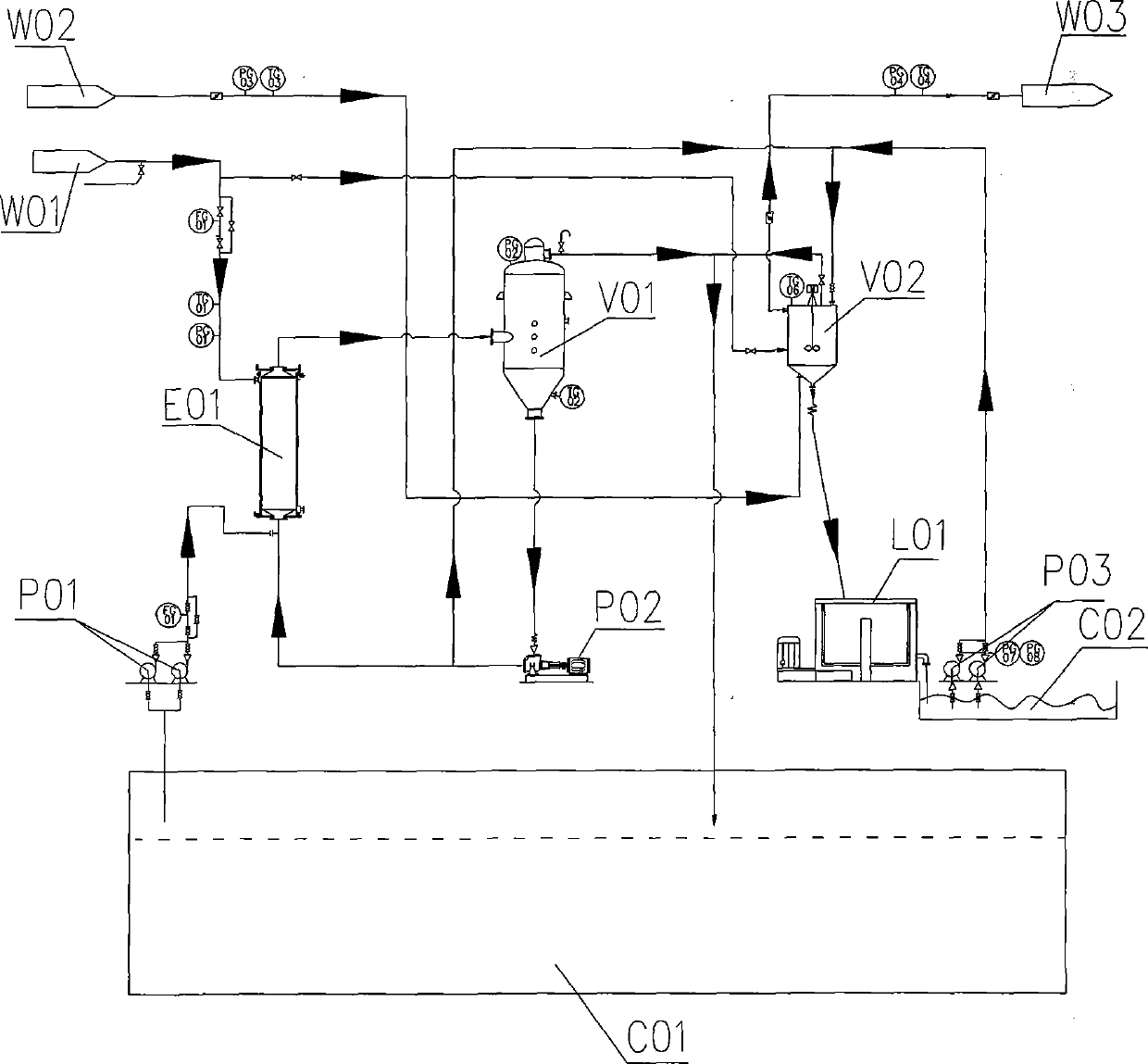

[0014] Such as figure 1 As shown, the energy-saving and environmentally-friendly pickling equipment of the present invention includes pickling tank C01, filtrate tank C02, feeding pump P01, circulating pump P02, slurry pump P03, heating chamber E01, separation chamber V01, crystallization chamber V02, and centrifuge L01, steam generating equipment W01, circulating water device W02 and circulating water return device W03; steam generating equipment W01 is used to pump steam into the heating chamber E01, and the feeding pump P01 is used to pump the acid in the pickling tank C01 Pump into the heating chamber E01, the output end of the heating chamber E01 is connected to the input end of the separation chamber V01,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com