Forward and reverse grate comprehensive system

A comprehensive system and grate technology, applied in the direction of grate, incinerator, combustion method, etc., can solve the problem of inability to realize the composite adjustment of the grate sheet structure, and achieve the effect of reducing difficulty, reducing labor intensity and simplifying assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

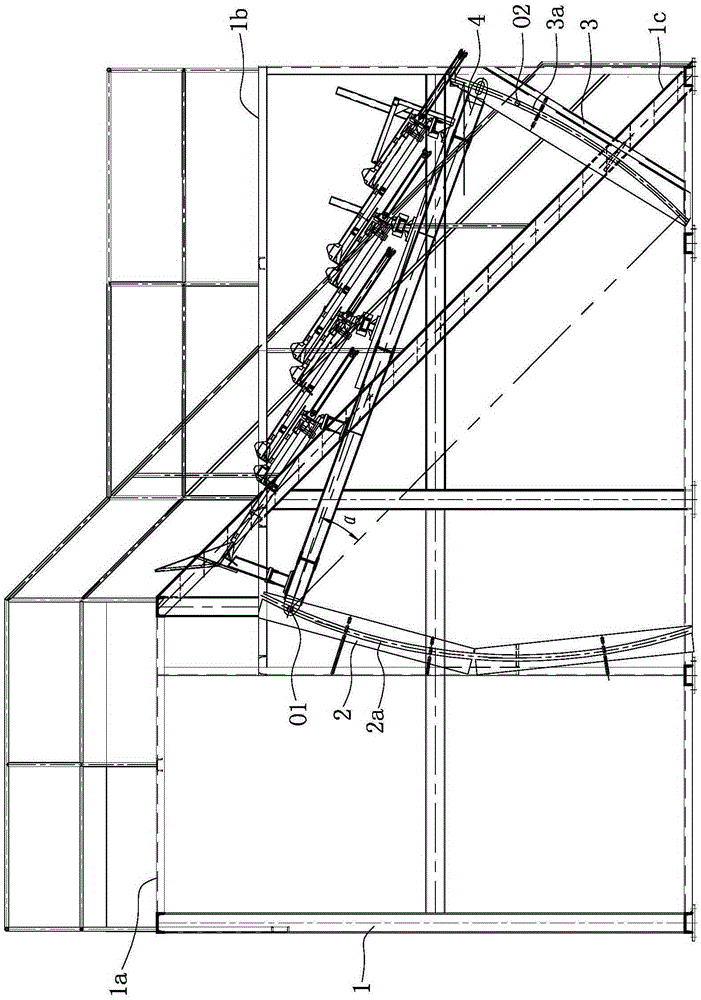

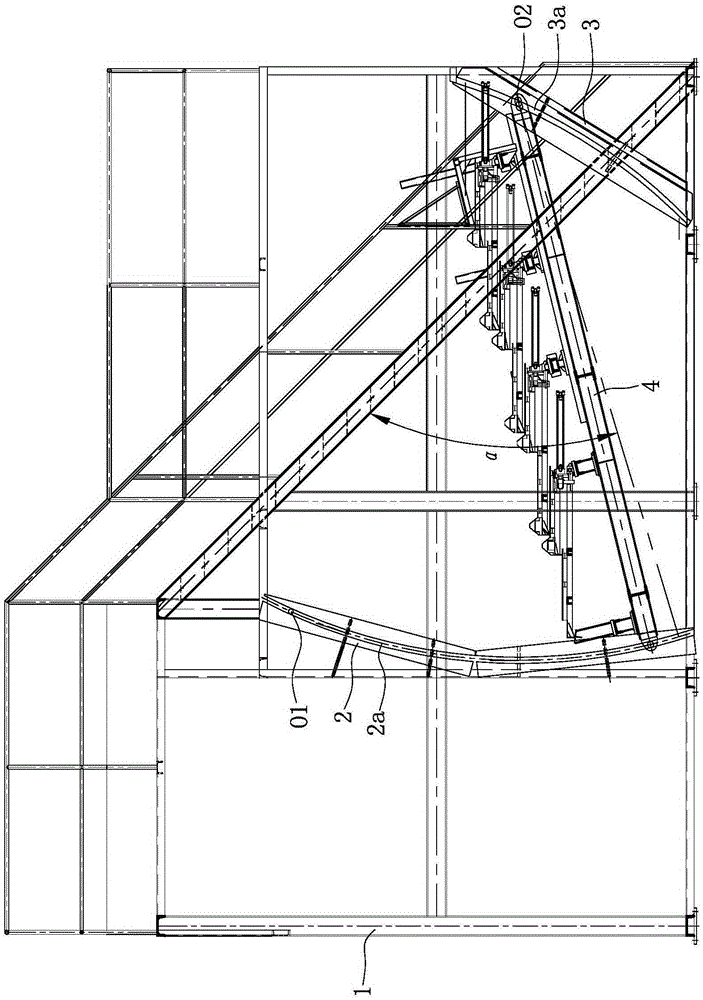

[0030] Such as figure 1 , figure 2 As shown, the platform support frame 1 is a three-dimensional frame structure, and the top of the platform support frame 1 is fixedly provided with a first platform 1a and a second platform 1b, and the first platform 1a is located in front of the second platform 1b, both of which are connected to The ground is parallel. The first platform 1a is connected to the ground through a ladder 1c with a front height and a rear height, and the first platform 1a and the second platform 1b are also connected through a ladder.

[0031] Such as figure 1 , figure 2 As shown, in the front part of the platform support frame 1, there are two left and right symmetrical forward push rails 2 fixedly arranged, and the relative positions of the two forward push rails 2 are provided with forward push guide grooves 2a, and the forward push guide grooves 2a on the left and right sides Relatively symmetrical. The rear end in the platform support frame 1 is fixed...

Embodiment 2

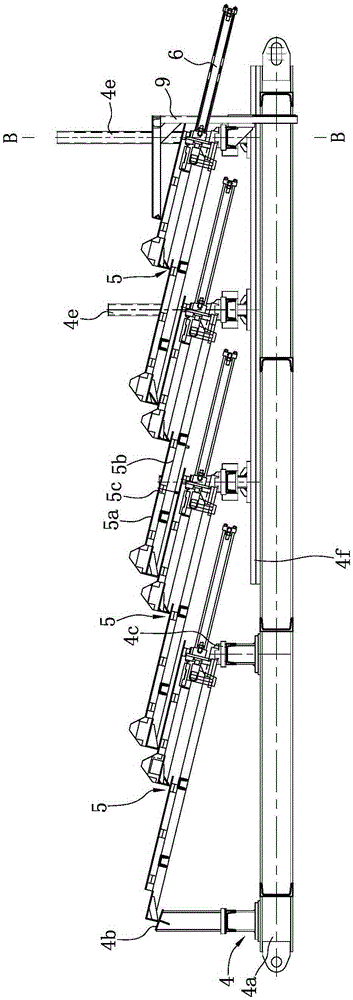

[0040] refer to Figure 5 , In this embodiment, the driving device 6 is a driving rod, and correspondingly, the positioning seat is a guiding seat. The driving rod is installed on the guide seat, the front end of the driving rod is connected with the driving support, and the driving rods of the multi-stage standard fire grate module 5 are connected into one, jointly driving the movable fire grate to reciprocate. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com