Waste heat recovery thermal power plant energy storage method and system

A waste heat recovery and thermal power plant technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as insufficient heat sources and energy shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

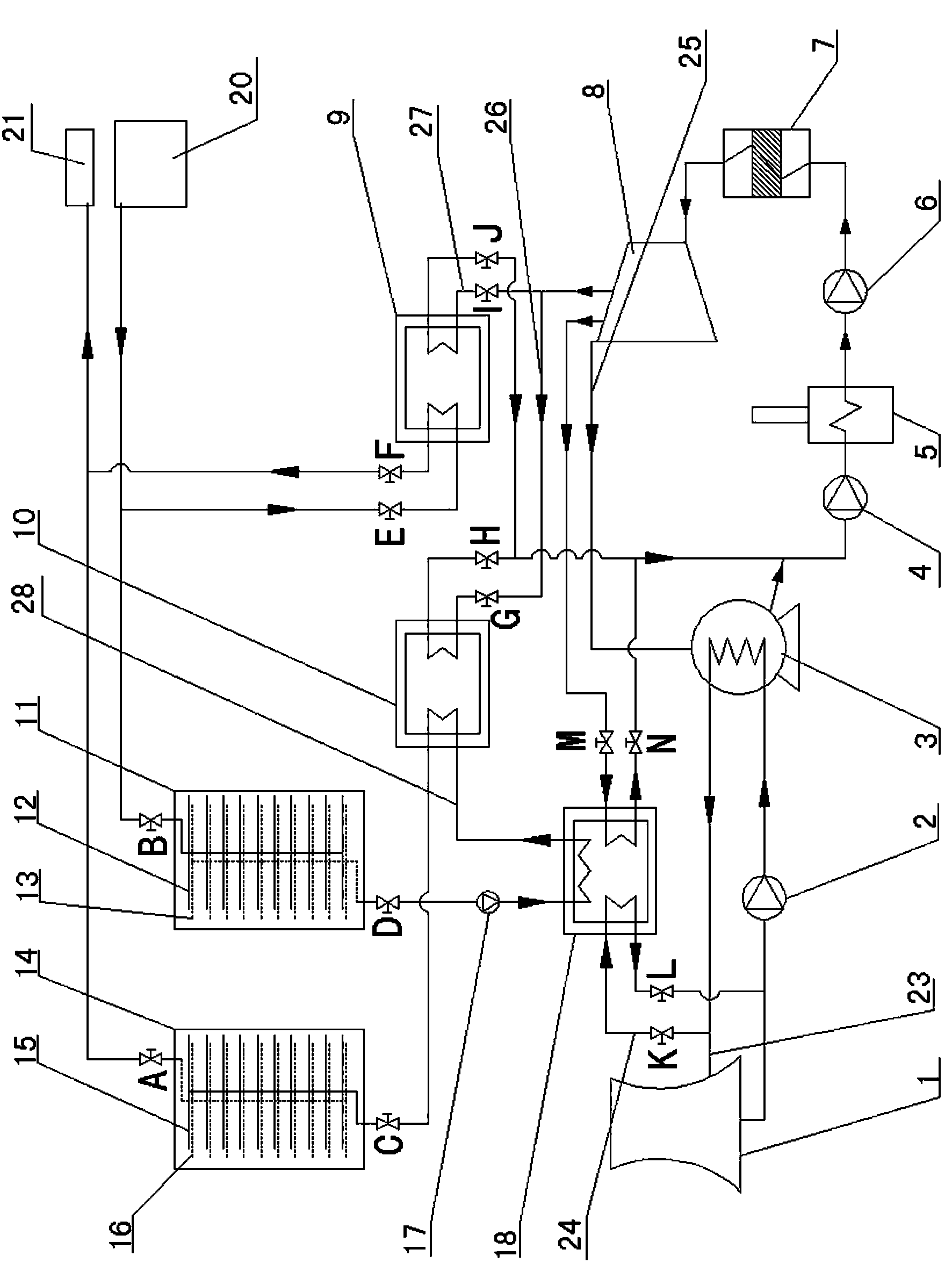

[0015] Below in conjunction with accompanying drawing, the present invention will be further described.

[0016] Such as figure 1 Shown is an energy storage method for waste heat recovery thermal power plants. During the day in the heating season, all the power generated by the power unit is used to generate electricity, and the energy storage water is used to bear the entire heating system; at night in the heating season, steam is extracted from the low-pressure cylinder of the steam turbine in the power unit. The steam extracted from the outlet drives the primary heating unit to heat the 60°C heat network return water obtained from the heat network return water unit 20 to 80°C, and then the steam turbine heats the steam extracted from the steam extraction port to drive the secondary heating unit to heat the heated water to 80°C. The return water at 80°C continues to be heated to 120°C, and the energy storage water at 120°C is used as the heat source for the heating system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com