Circulating fluidized bed device with drying and crushing functions

A circulating fluidized bed, functional technology, used in lighting and heating equipment, drying solid materials, heating to dry solid materials, etc., can solve the problems of low output of dryer, poor circulation, complex equipment structure, etc., to achieve high output , the effect of good circulation and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0019] The first embodiment: a circulating fluidized bed equipment with drying and crushing functions.

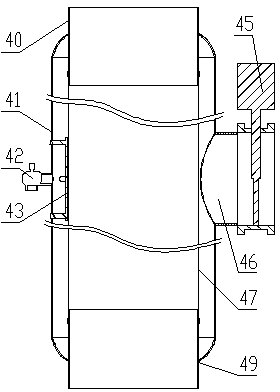

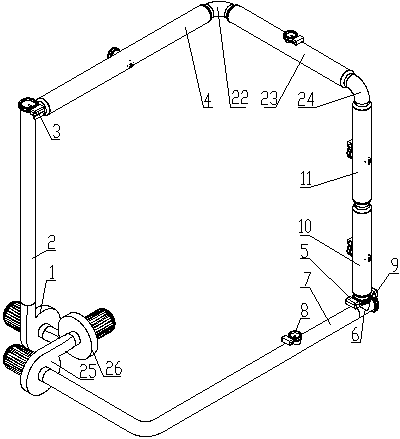

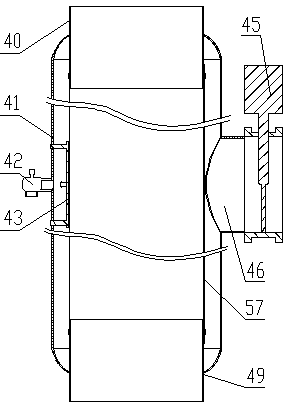

[0020] see Figure 1 to Figure 3 , the circulating fluidized bed equipment with drying and crushing functions includes a fan 1, a circulation pipeline I2, a dust collector 4, a classifying device 10, a regulating valve 5, an air inlet tee 6, and a circulation pipeline II7. Exit, circulation pipeline I2, dust collector 4 intake pipe 40, dust collector 4 ash discharge pipe 49, classification device 10 intake pipe 40, classification device 10 ash discharge pipe 49, regulating valve 5, intake tee 6, circulation pipeline Ⅱ7. The inlet of the fan 1 is connected in order to form a circulation channel; there is a discharge port on the circulation line Ⅰ2, and a discharge valve 3 is installed on the discharge port; there is a feeding port on the circulation line Ⅱ7, and a feeding valve 8 is installed on the feeding port. Another port of gas tee 6 is an air inlet, and air inlet valv...

no. 2 example

[0023] The second embodiment: a circulating fluidized bed device with drying and crushing functions.

[0024] see Figure 4 , the circulating fluidized bed equipment with drying and crushing functions includes fan 1, circulation pipeline I2, dust collector 4, pipeline A22, dust collector 23, pipeline B24, classification device 11, classification device 10, regulating valve 5, air intake Tee 6, circulation pipeline II 7, fan 25, fan 26, the connection of the above-mentioned components is different from the first embodiment in that: one is to connect in series between the ash discharge pipe of the dust collector 4 and the intake pipe of the classification device 10 Pipeline A22, deduster 23, pipeline B24, and classifier 11 connected in sequence are provided. The second is that fan 25 and blower fan 26 connected in sequence are connected in series between the inlet of circulation pipeline II7 and blower fan 1.

[0025] The circulating fluidized bed equipment with drying and crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com