Chip card box for pretreatment before food sample detection

A chip and sample technology, applied in the preparation of test samples, etc., can solve the problems that the actual situation of the sample cannot be truly reflected, the detection equipment is expensive, and it is not easy to carry, so as to improve the pre-processing efficiency, shorten the pre-processing time, reduce the The effect of manual manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

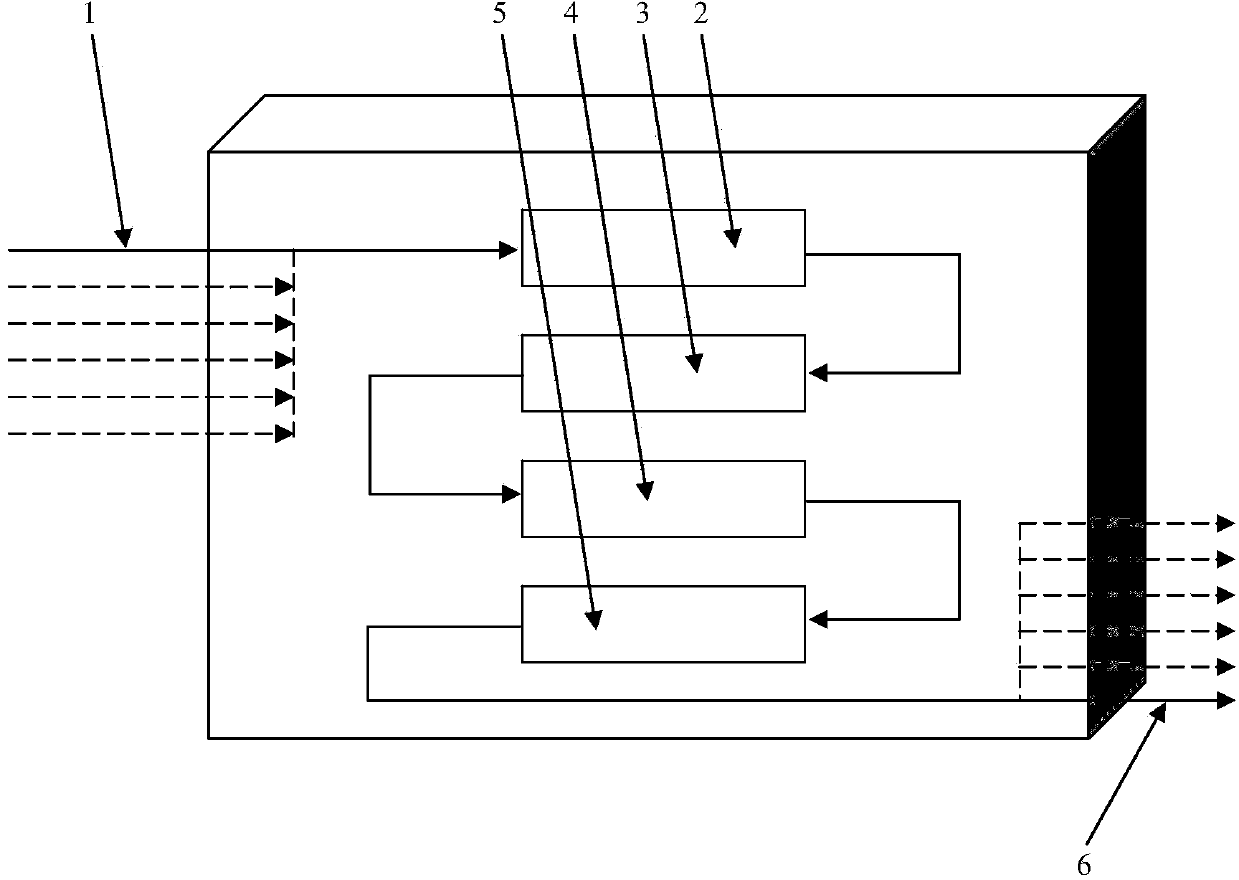

[0044] see figure 1 , the pre-processing cartridge chip with a metal, plastic or other material shell is composed of one or more functional units, these functional units include extraction unit 2, separation unit 3, derivatization unit 4, enrichment unit 5 and so on. The functional units are connected in series through pipelines (in other embodiments, they may also be connected in parallel or in series and parallel combinations through pipelines). These functional units have specific dimensions, shapes, compositions, internal structures and manufacturing methods to realize their functions. The pre-treatment cartridge chip has one or more inlets 1, which respectively introduce the solvent or solution required for the extraction and pre-treatment functional units, so as to complete the pre-treatment steps. The inlet 1 is connected to an extraction unit 2 . The pre-processing cartridge chip also has one or more outlets 6 connected to the enrichment unit 5 . The pretreatment pr...

Embodiment 2

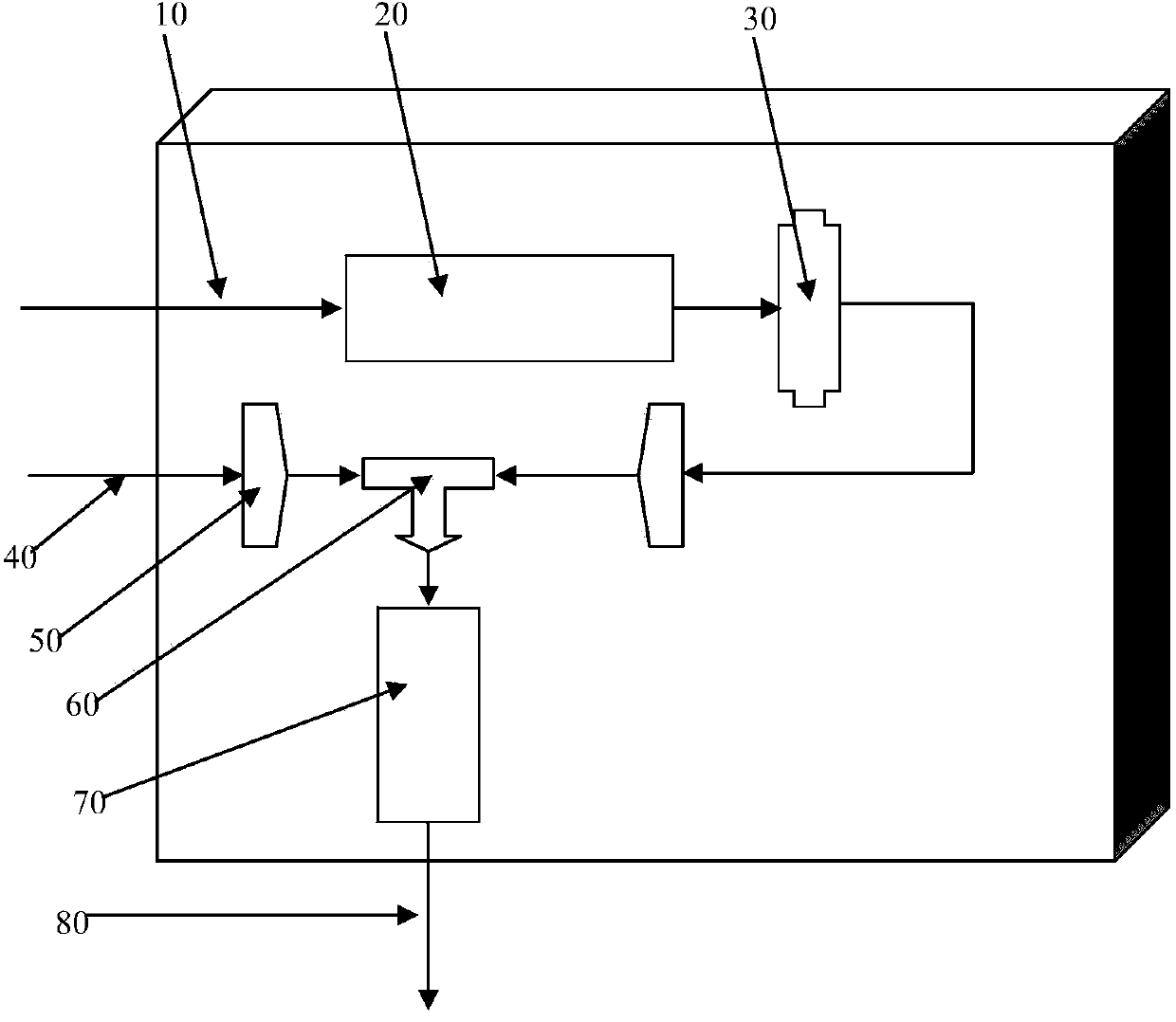

[0046] see figure 2 , The pre-treatment cartridge chip is used for the pre-treatment of flour whitening agent in flour. The cartridge chip has a shell made of plexiglass, and its dimensions are 10cm×8cm×2cm. The cartridge chip is provided with the following functional units: a sample tank 20, a filter 30, a mixer 60, a solid phase extraction column 70, and a one-way valve 50 for flow path control. The cartridge chip also includes two inlets 10 , 40 and an outlet 80 .

[0047] The sample tank 20 is an empty tube (about 1.5 cm in diameter and about 5 cm in length) with both ends closed, one end is connected to the inlet 10 , and the outlet end is connected to the inlet of the filter 30 . There is also an opening for the filling of flour samples.

[0048] A 0.22-micron filter membrane is installed in the filter 30 (disc-shaped, 1.3 cm in diameter), which can intercept small solid particles in the extraction liquid.

[0049] The mixer 60 is a T-shaped tee (its dimensions are ...

Embodiment 3

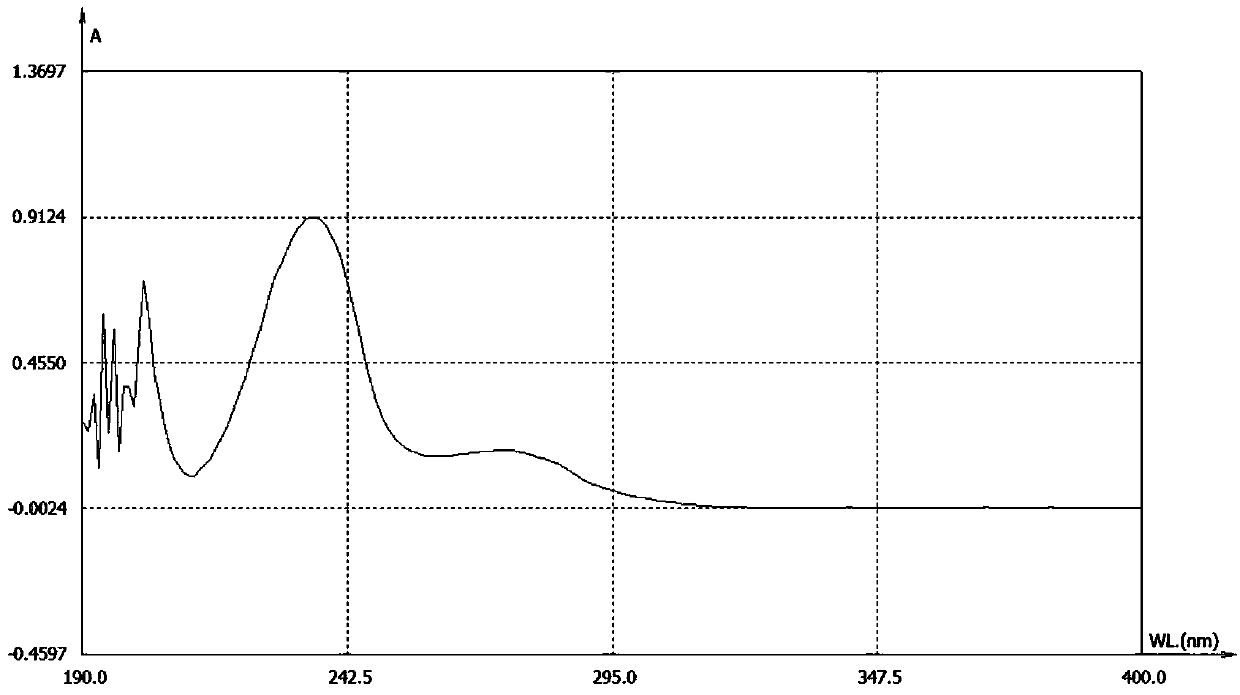

[0053] The detection of embodiment 3 flour brighteners

[0054] After the chip of embodiment 2 is prepared, carry out the detection of flour whitening agent

[0055] The pretreatment process is as follows: Methanol first flows into the solid phase extraction column 70 through the inlet 40 to activate it. Then flour was added into the sample tank 20 , acetone flowed into the inlet 10 at a flow rate of 1 ml / min, and flowed through the sample tank 20 . The acetone dissolves and extracts the flour whitener and some other components in the flour. The extraction liquid flows through the filter 30 , wherein the solid residue and flour particles are intercepted, and the clarified extraction liquid enters the mixer 60 through the one-way valve 50 . At this time, water flows in from the inlet 40, and also flows into the mixer 60 through the one-way valve 50 to mix with the extraction liquid. Keep the volume flow ratio of the extract solution / water at 2:3, and the mixed solution enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap