Laminated module and interposer used in same

A stacking module and intermediary technology, applied in the field of stacking modules, can solve problems such as thermal instability of stacking modules, achieve the effects of suppressing temperature rise, high cooling capacity, and suppressing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

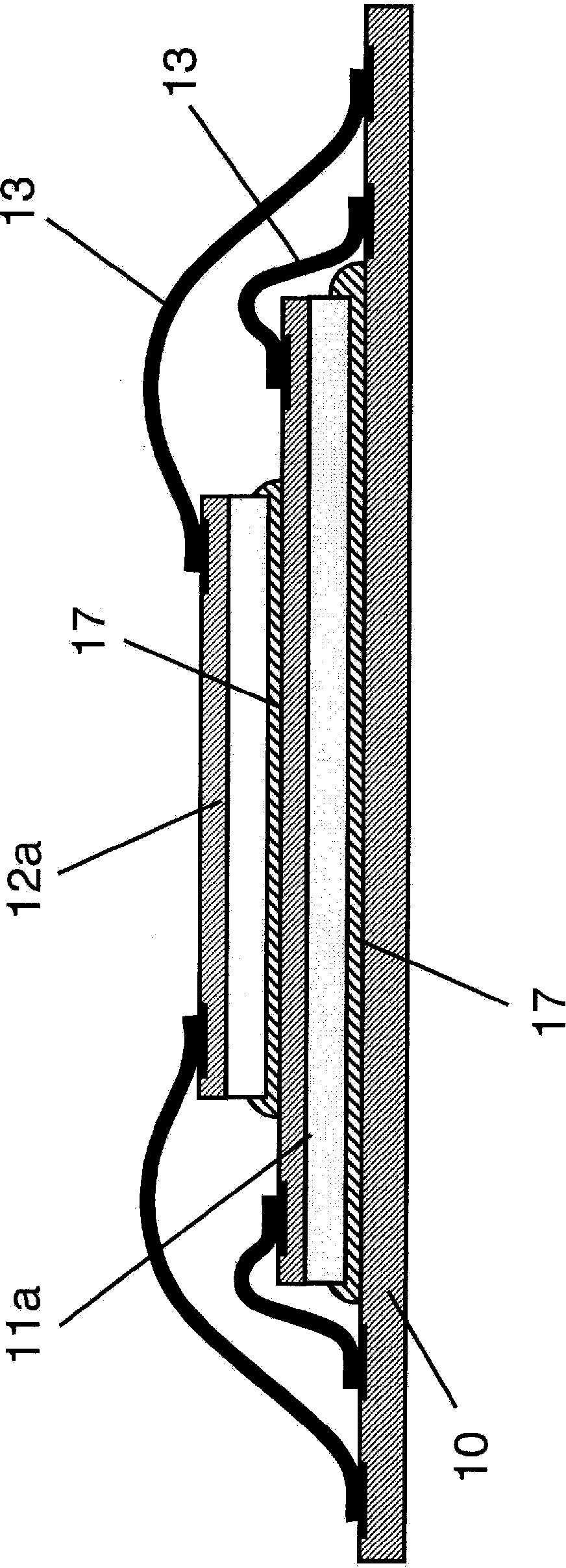

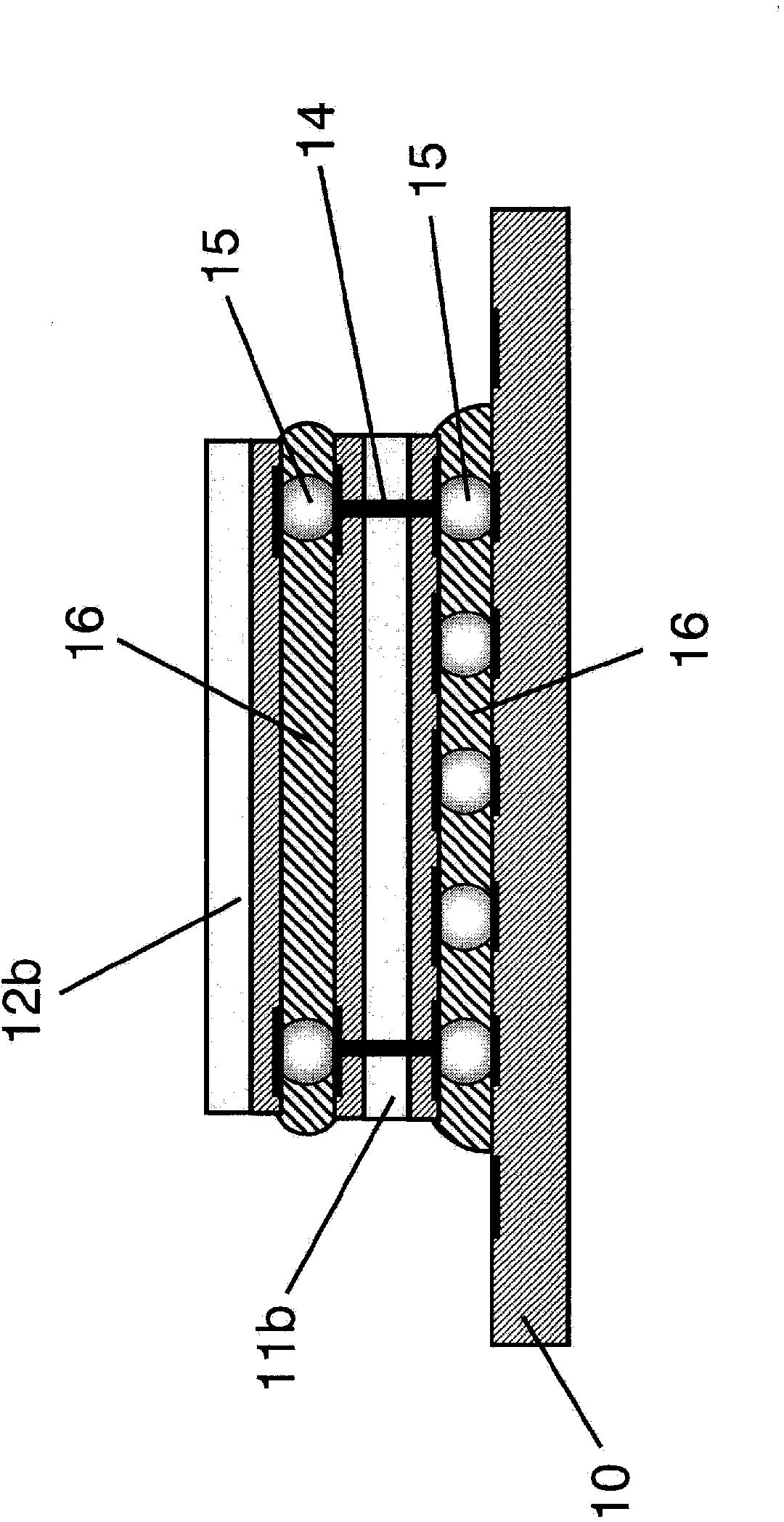

[0311] (the stacked module of Embodiment 1, and the interposer used)

[0312] Figure 21A ~ Figure 21C It is the interlayer 70 used in Embodiment 1 to increase the cooling effect by utilizing the adiabatic expansion of the fluid. Figure 21A is its exploded stereogram, Figure 21B is its stereogram, Figure 21C is its cross-sectional view.

[0313] In the interposer 70, at least one of the heat radiation layer 61b and the heat reflective layer 61a used by the interposer 30 can be used,

[0314] Interposer 70 as Figure 21A ~ Figure 21C As shown, it consists of a rectangular plate-shaped upper wall 73, a rectangular plate-shaped lower wall 74, a pair of side walls 72a and 72b, and the four members form a channel 71 inside. The side walls 72a and 72b are symmetrical in shape, and the channel 71 becomes wider in a certain range from the upstream end and narrows in a certain range from the downstream end. Between the wide part and the narrow part on the upstream side of the ...

Embodiment 2

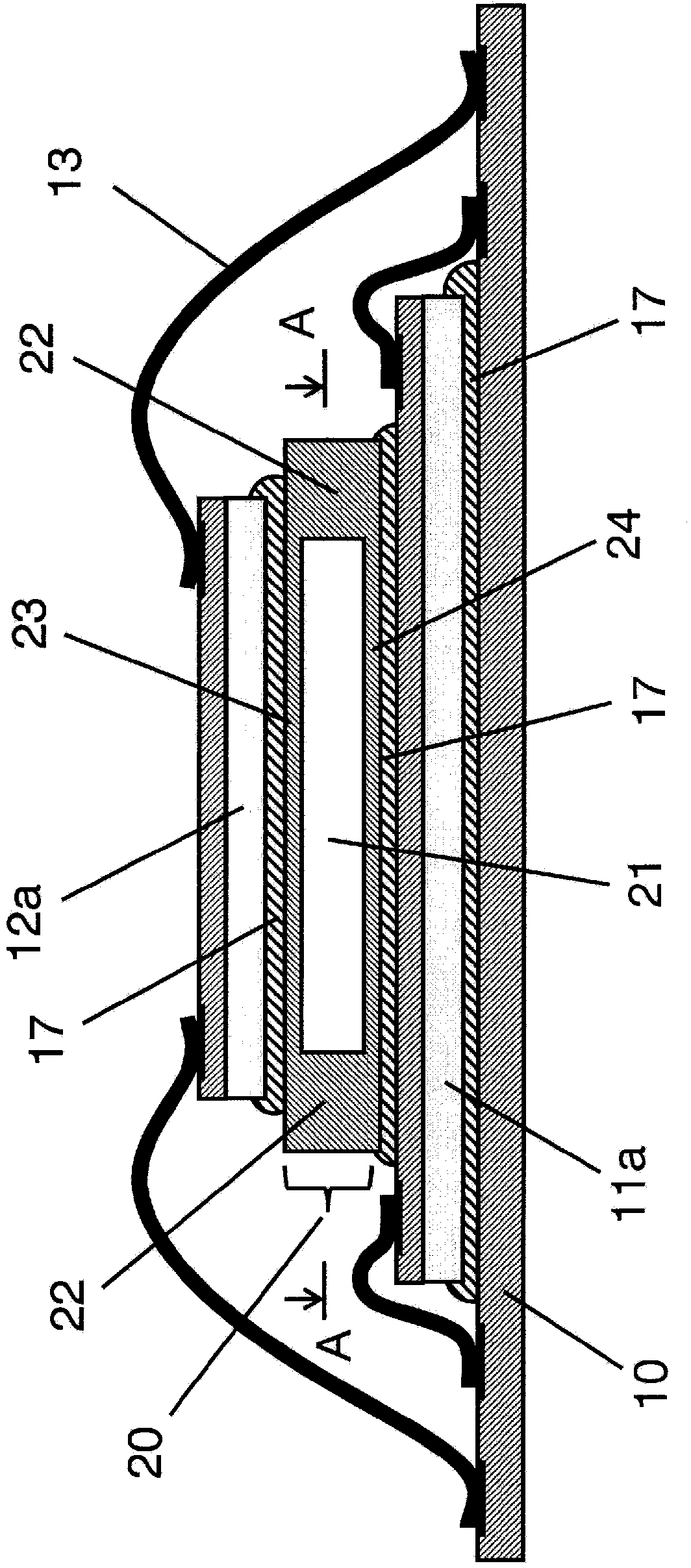

[0322] (Example 2 stacked module package structure and interposer used)

[0323] Figure 23A yes Figure 21A ~ Figure 21C Interposer 70 shown assembled in Figure 3A and Figure 3B The package structure of the stacked module in Embodiment 2 formed by penetrating the electrode module is shown. Figure 23B Channels 71 of interposer 70 are shown.

[0324] Figure 23A The packaging structure, except for the interposer 70 that replaces the interposer 30, the rest are the same as Figure 3A and Figure 3B The bonding modules shown are the same, and descriptions are omitted here. Figure 23A In , the fluid L flows from the front of the paper to the rear along the direction perpendicular to the paper.

[0325] Figure 23A The same is true for the package structure, and an interposer 70 having an "adiabatic expansion structure" is arranged between the first semiconductor device 11b on the lower side and the second semiconductor device 12b on the upper side, and Figure 22A Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com