Film-cutting removing and film-lifting winding type mulching film picking machine

A technology for picking up machines and film rolls, which is applied to collectors, mechanical equipment, agricultural machinery and tools, etc. It can solve the problems of white pollution and aggravation that waste plastic films cannot be effectively recycled and reused, so as to save operating costs, reduce labor intensity, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

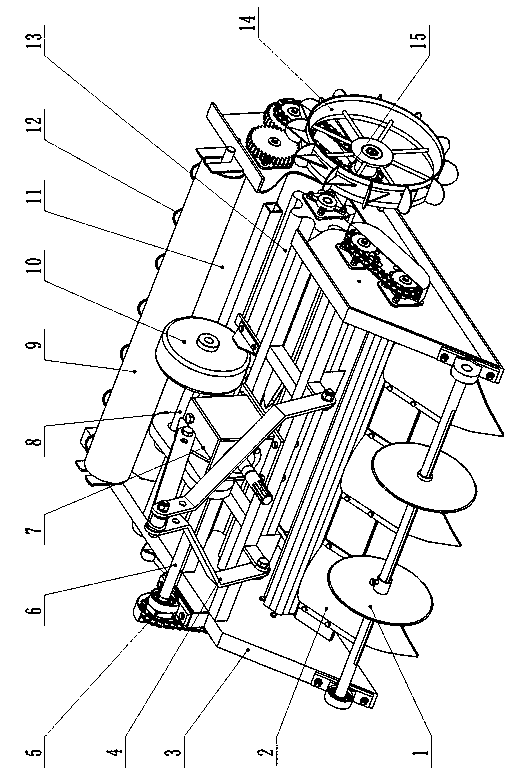

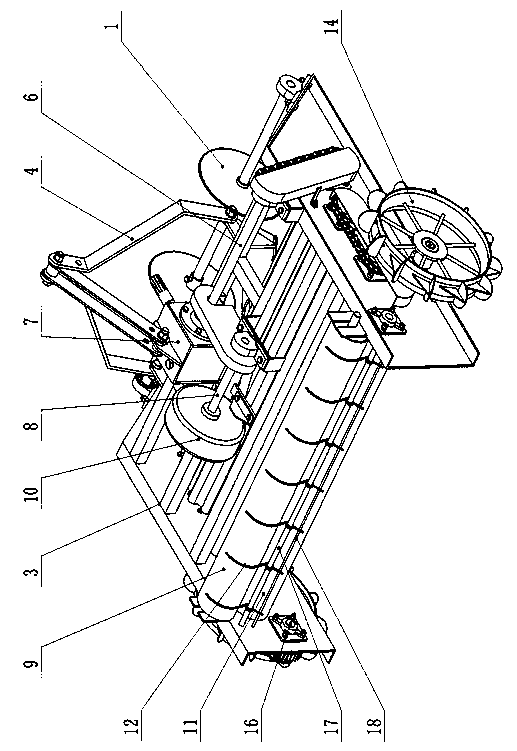

[0024] like figure 1 , figure 2 As shown, a film cutting and clearing film winding type mulch picking machine includes a frame 3, a suspension frame 4 installed on the frame 3, ground wheels 14 installed on both sides of the frame 3, and a transmission mechanism. The film cutting mechanism is installed at the front and bottom of the frame 3, and the film lifting mechanism is installed on the frame behind the film cutting mechanism; 3. A plastic film winding mechanism is installed on the upper rear, and the plastic film winding mechanism is located at the rear of the shaking and clearing soil conveying mechanism.

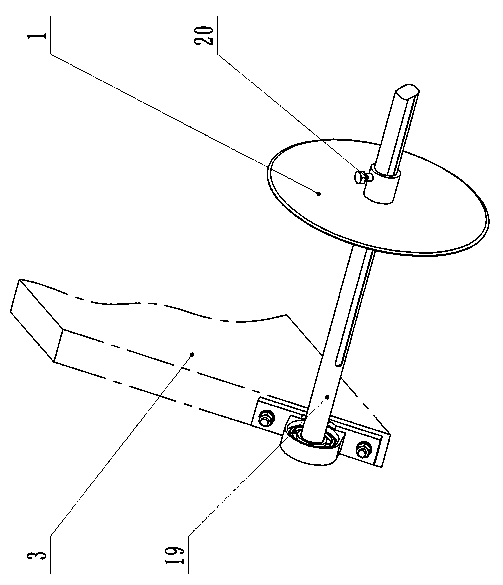

[0025] like image 3 As shown, the film cutting mechanism includes a disc cutter 1, and the disc cutter 1 is installed on the cutter shaft 19, and the cutter shaft 19 is installed on the front and bottom of the frame 3 through a bearing seat. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com