Vortex dough mixer

A dough mixer and curved surface technology, which is applied in the direction of mixing/kneading with vertical installation tools, can solve the problems of large power consumption, complex structure, and difficult cleaning, and achieve low power consumption, simple and compact structure, and dough quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

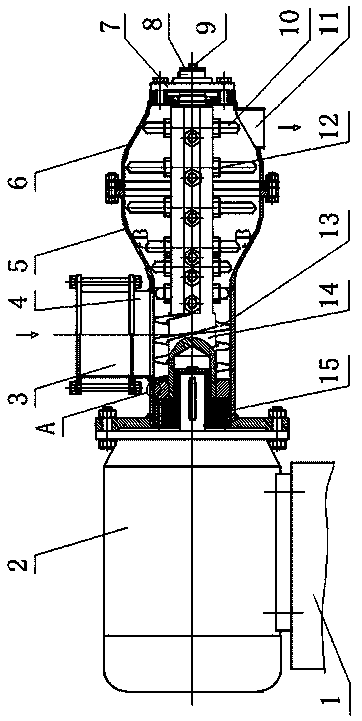

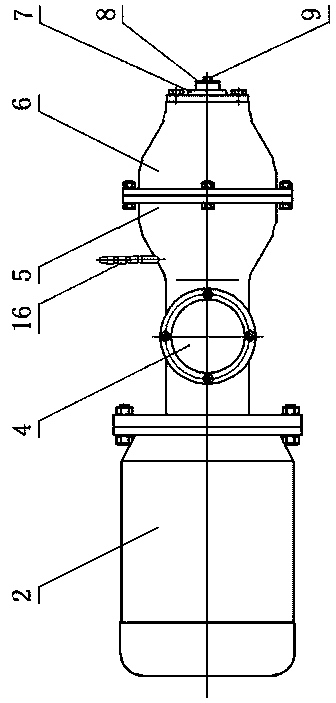

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

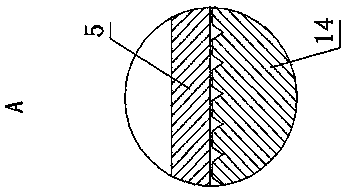

[0014] like Figure 1 to Figure 4 As shown, a kind of vortex kneading machine provided by the present invention includes a base 1, a motor 2 fixed on the base 1 with bolts, an outer gear 15 of a gear coupling is installed on the power output shaft of the motor, and the front change The radially curved shell 5 is fastened on the motor 2 by means of flange bolt connection, the front end of the main shaft 14 of the kneading machine is made with an internal gear of a gear coupling, and the main shaft of the kneading machine 14 corresponds to the outer cylindrical surface of the feeding port 4 The feeding auger blade 13 is welded, and the main shaft 14 of the dough mixing machine is correspondingly equipped with a plurality of stirring teeth 10 in the inner part of the dough mixing chamber. The stirring teeth 10 correspond to different chamber inner diameters and have diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com