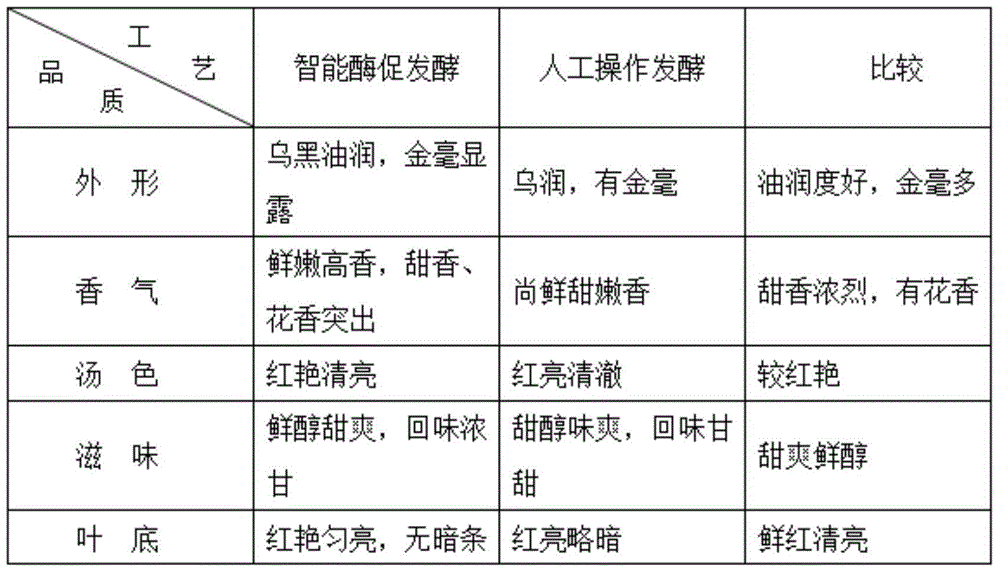

A method for the production of black tea by artificial intelligence enzymatic fermentation

An enzymatic fermentation and artificial intelligence technology, applied in the fields of oxygen supply and saccharification enzyme biological enzymatic fermentation, humidification, and intelligent temperature control of black tea, can solve problems such as poor quality of black tea, achieve significant ecological benefits, protect the ecological environment, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A spring tea intelligent enzymatic fermentation process

[0026] (1) Picking of fresh leaves: Picking standard: one bud and one leaf, and the first two leaves.

[0027] (2) Cold air withering: Start the blower in the withering tank, blow natural cold air, wither and spread the leaves to a thickness of 4-5 cm, and the time is 2 hours.

[0028] (3) Hot air withering: wither in the withering tank with hot air, set the artificial intelligence temperature control device to set the leaf temperature at 37-39°C, and wither for 5-6 hours (5 hours on sunny days and 6 hours on cloudy days). If it is found that the withering overtime device alarms, stop the withering immediately and enter the kneading process.

[0029] (4) Enzyme kneading: use 6CR-55 kneading machine for kneading, kneading speed is 32 revolutions per minute, after kneading for 10 minutes, evenly sprinkle 0.5% powdered glucoamylase into the kneading barrel and mix well up and down , then press and knead for 35 min...

example 2

[0038] A kind of summer tea intelligent enzymatic fermentation process

[0039] 1. Picking fresh leaves: pick one bud and two leaves, the more tender the better.

[0040] 2. Cold wind withering: Blow natural cold wind in the withering tank. Due to the high temperature in summer, the buds and leaves should be spread thinly by 3-4 cm, and the time is slightly shorter, about 1 hour.

[0041]3. Hot air withering: Due to the high temperature, the intelligent control system is fixed at 32-33°C for 3.5 hours. This withered state is conducive to the natural oxidation of tea polyphenols.

[0042] 4. Add enzyme and knead: adjust the speed of kneading machine, knead at 35 rpm, reduce the amount of glucoamylase added to 0.4%, and dilute glucoamylase with water at 1:5 and evenly sprinkle it into the kneading leaves. For the purpose of dilution, due to the high temperature in summer, dry kneading with powdered glucoamylase will affect the activity of biological enzymes. In the kneading p...

example 3

[0051] A kind of intelligent enzymatic fermentation process of autumn tea

[0052] 1. Picking of fresh leaves: the picking standard is mainly one bud and one or two leaves, and the old stem buds and leaves should be picked as little as possible.

[0053] 2. Cold wind withering: Spread 2-3 cm thinly and blow cold wind for 1-1.5 hours.

[0054] 3. Hot air withering: withering leaf temperature ≤ 33 ℃, time ≤ 3 hours.

[0055] 4. Adding enzyme and kneading: the amount of enzyme added is 0.4%, and the kneading time is the same as that of summer tea.

[0056] 5. Deblocking and screening: fast deblocking, 2-3 minutes.

[0057] 6. Enzymatic fermentation: temperature ≤ 35 ℃, humidification rate ≤ 90%, oxygen supply every 15 minutes.

[0058] 7. Initial drying with hot air: temperature ≤ 92°C, time ≤ 6 minutes, moisture content of dried leaves ≤ 50%.

[0059] 8. Hot air foot drying: temperature ≤ 90 ℃, time 4 minutes.

[0060] 9. Far-infrared aromatherapy: temperature ≤ 83 ℃, time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com