Special cocamidopropyl betaine for firefighting foam extinguishing agent and preparation method of special cocamidopropyl betaine

A technology of cocamidopropyl betaine and foam fire extinguishing agent, which is applied to fire protection equipment and other directions, can solve the problems of great influence on foam performance and fire extinguishing performance, inability to quickly put out oil fires, etc., and achieves strong oleophobicity and accelerated The effect of fluidity and film-forming promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

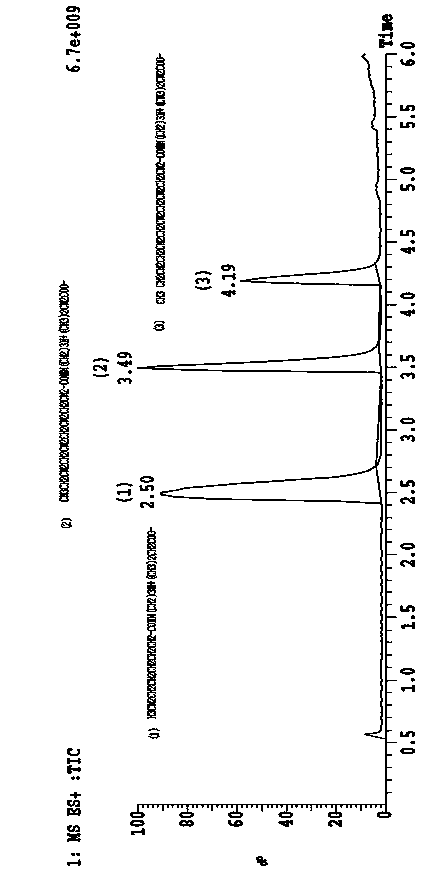

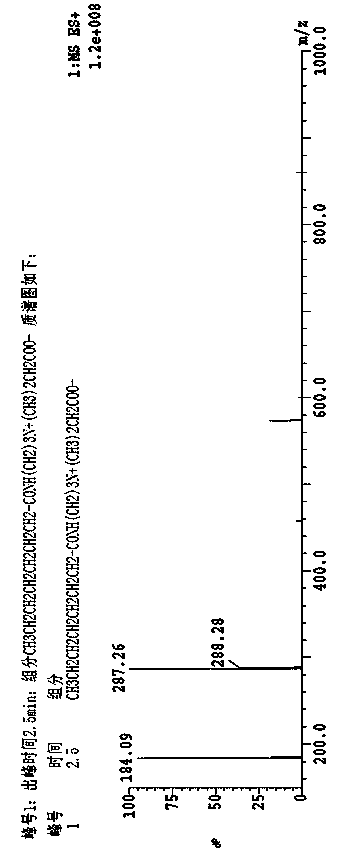

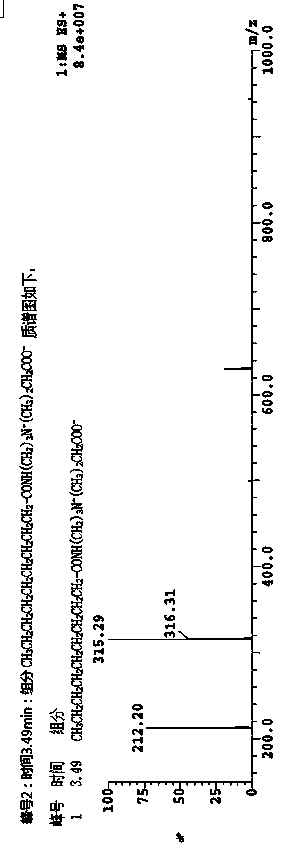

Image

Examples

Embodiment Construction

[0071] 1. Synthesis process:

[0072] 1. Preparation method one:

[0073] The amount of raw materials to be taken is based on the molar ratio of medium chain triglyceride (MCT), dimethylpropylenediamine, KOH and sodium chloroacetate as 1:3.1:0.01:2.85.

[0074] Among them, among medium chain triglycerides (MCT), C8≥53%, and 36%≤C10≤47%.

[0075] Step 1: Add dimethylpropanediamine, KOH and medium-chain triglyceride (MCT) into the reactor and stir evenly, slowly raise the temperature to 130°C under the protection of nitrogen, and then keep it at 130-140°C for 6~ 8h. Sampling is carried out to detect the content of dimethylaminopropylamide, and when the content is greater than 95%, the reaction reaches the end point.

[0076] The reaction formula of this step is:

[0077]

[0078] Wherein R1, R2, R3 are respectively CH 3 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 (n-heptyl), CH 3 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 (n-nonyl) at least any one.

[0079]

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com