Surface modification method for contact lens with medicine delivery

A contact lens and surface modification technology, which is applied in glasses/goggles, ophthalmic treatment, optics, etc., can solve the problems of limited loading, lack of ligands for contact lenses, and limited ability of contact lenses to control drug release. The effect of social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

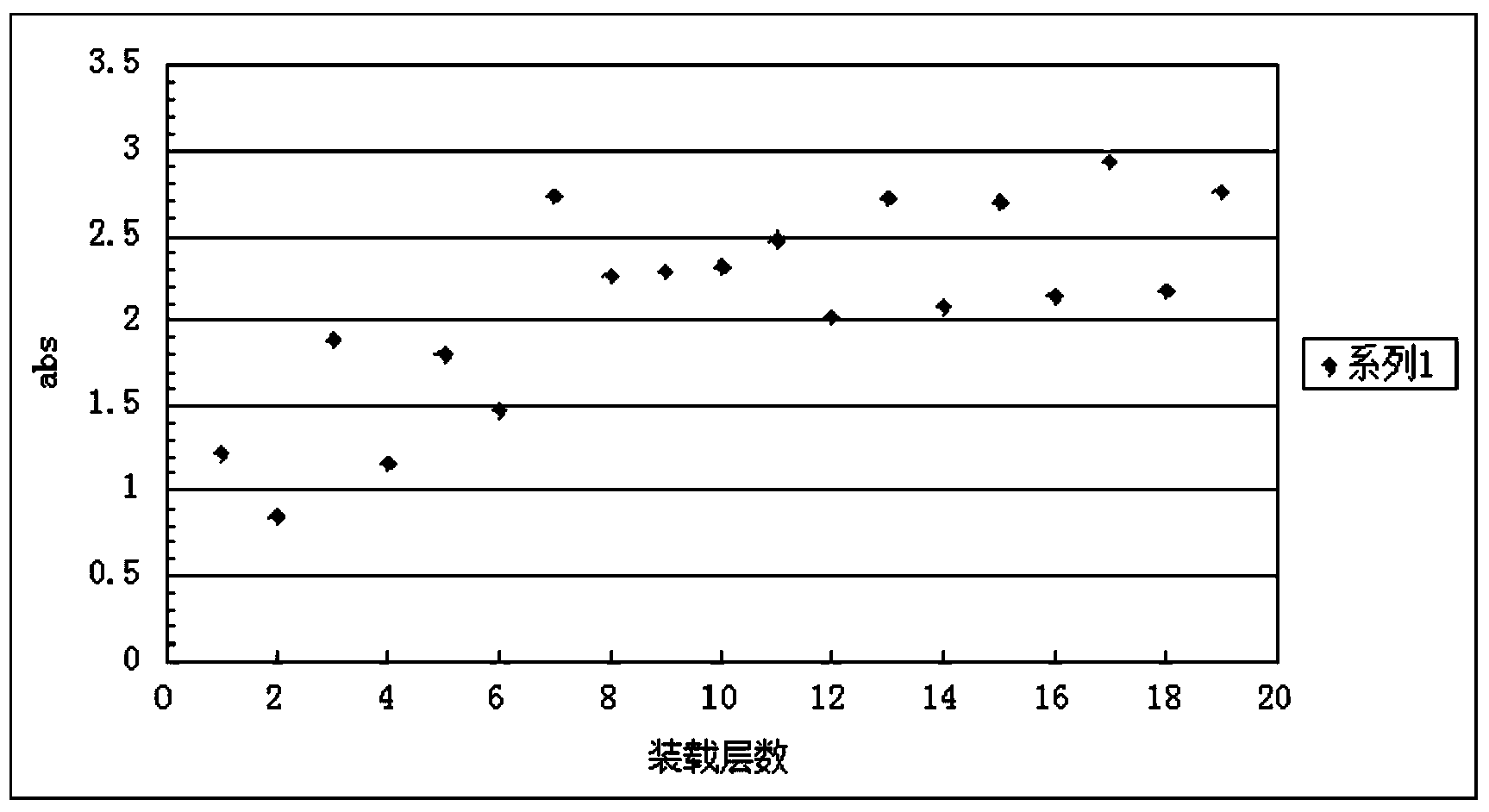

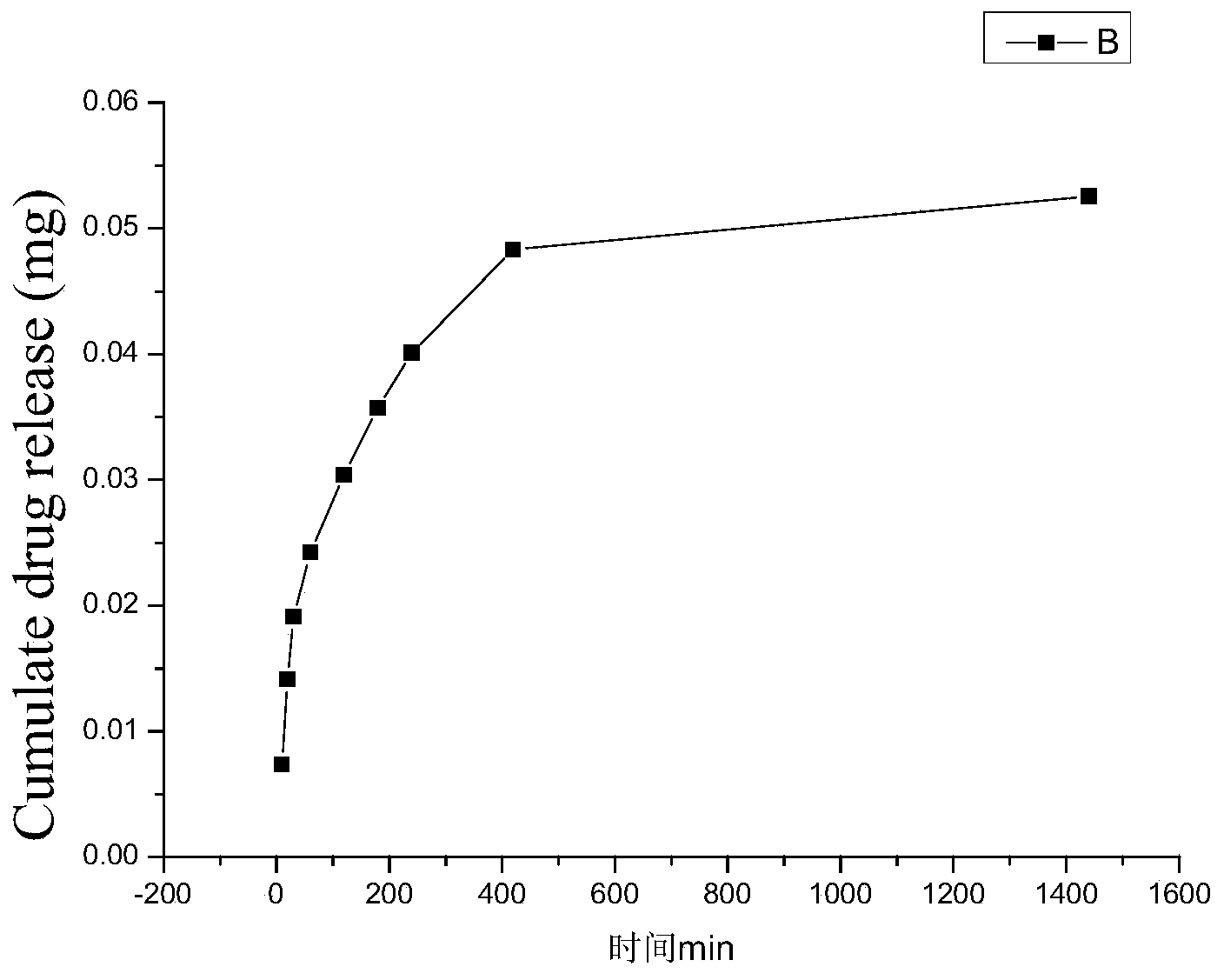

Embodiment 1

[0032] The polyelectrolyte PCM-β-CD and PEI were respectively formulated into 3mg / ml solutions, and then ofloxacin was dissolved in the PEI solution to obtain a final drug concentration of 1mg / ml. The contact lens is immersed in the PEI electrolyte solution containing the drug for 20 minutes, and then rinsed with 0.15M sodium chloride solution and blown dry after being taken out; the hydrogel sheet is put into the PCM-β-CD solution, soaked for 20 minutes, and then taken out with 0.15 Rinse with M sodium chloride solution and blow dry; repeat the above process until 20 layers are assembled.

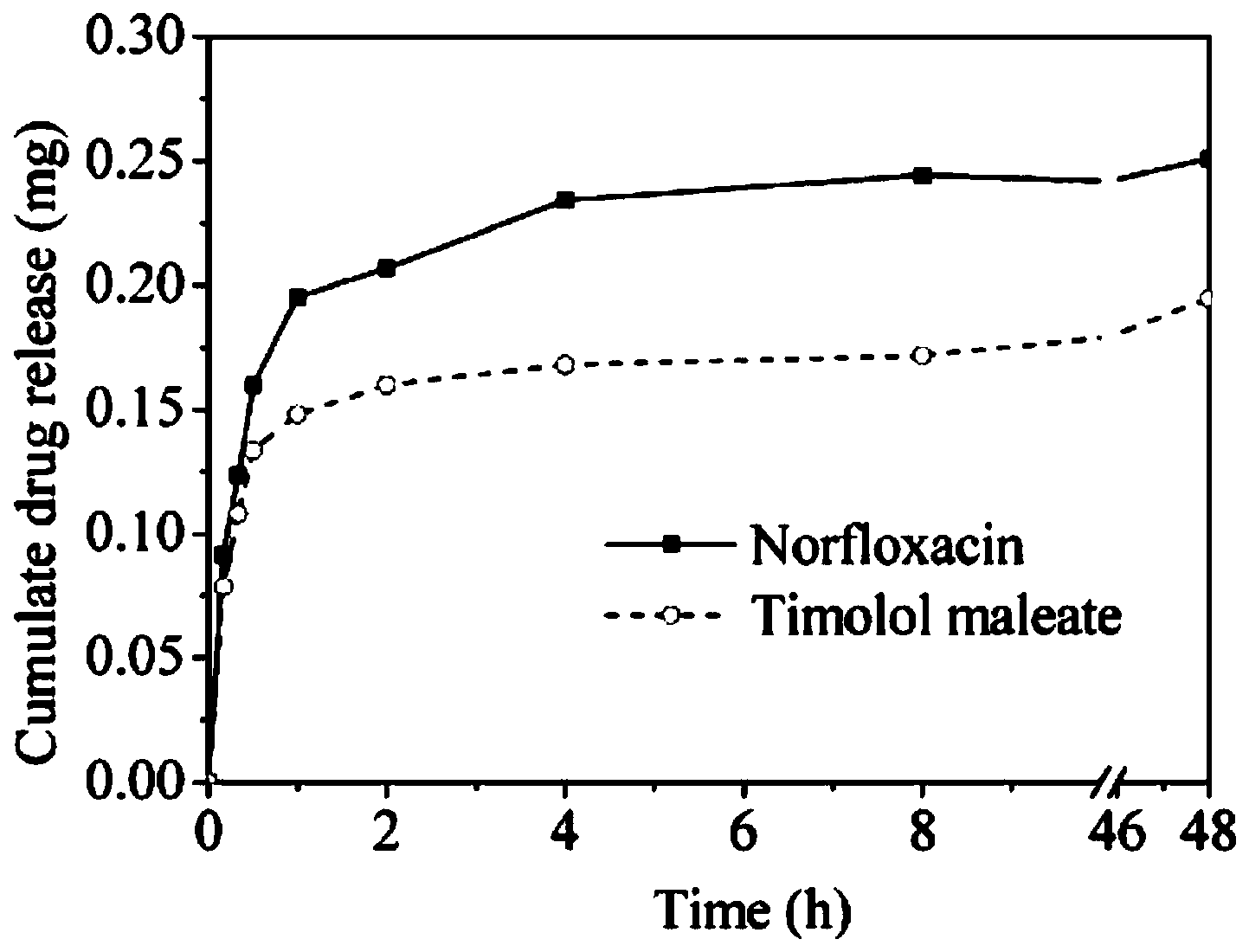

Embodiment 2

[0034] The polyelectrolyte PCM-β-CD and CS were prepared into 1 mg / ml solutions, and ofloxacin was dissolved in the CS solution to obtain a final drug concentration of 1 mg / ml. The contact lens is immersed in the CS electrolyte solution containing the drug for 20 minutes, and then rinsed with 0.15M sodium chloride solution and blown dry after being taken out; the hydrogel sheet is put into the PCM-β-CD solution, soaked for 20 minutes, and taken out with 0.15 Rinse with M sodium chloride solution and blow dry; repeat the above process until 20 layers are assembled.

Embodiment 3

[0036] The polyelectrolyte PCM-β-CD and PEI were respectively formulated into 3mg / ml solutions, and then ofloxacin was dissolved in the PEI solution to obtain a final drug concentration of 1mg / ml. The contact lens is immersed in the PEI electrolyte solution containing the drug for 20 minutes, and then rinsed with 0.15M sodium chloride solution and blown dry after being taken out; the hydrogel sheet is put into the PCM-β-CD solution, soaked for 20 minutes, and then taken out with 0.15 Rinse with M sodium chloride solution and blow dry; repeat the above process until 10 layers are assembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com