General method for laying out and assembling wedge-shaped duct pieces

A general-purpose wedge-shaped segment and wedge-shaped tube technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as fixed rotation angle, single staggered joint assembly form, and limited fitting accuracy of tunnel design axis, and achieve enhanced Integrity, improvement of assembly quality, convenient transportation and construction management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

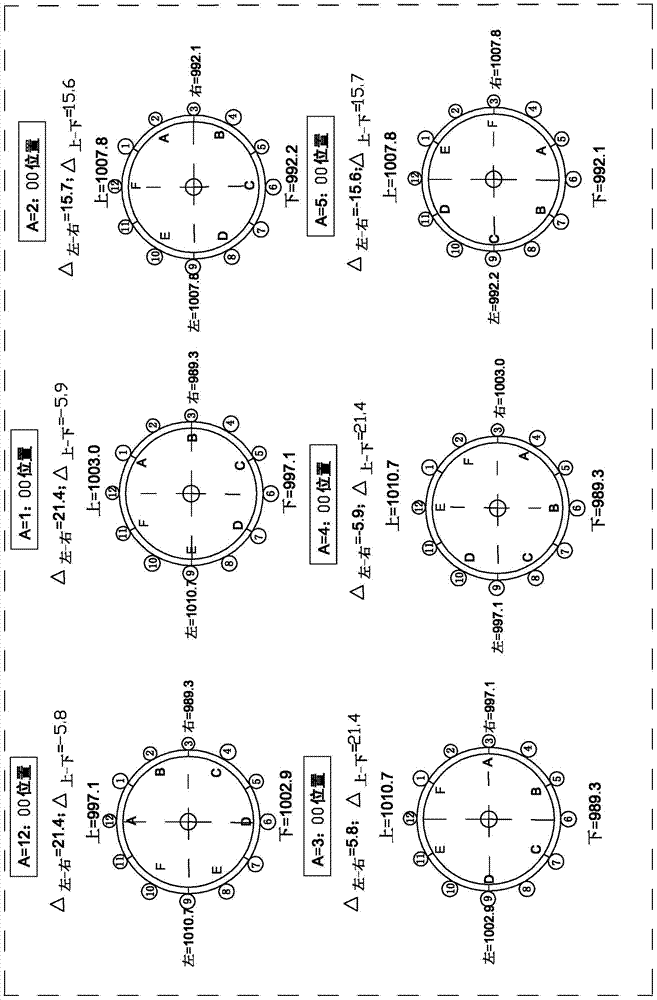

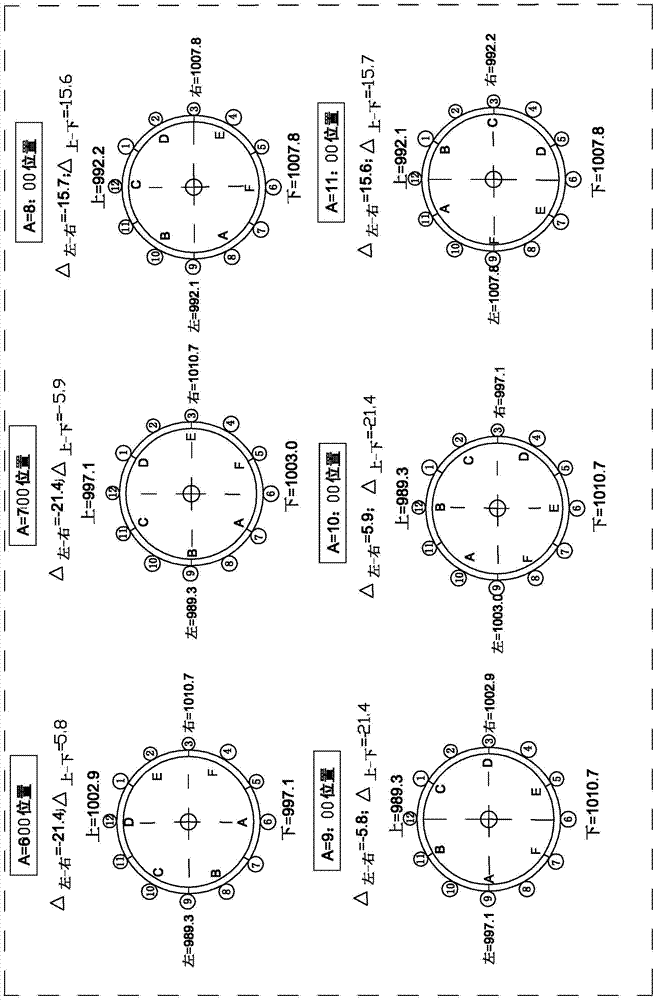

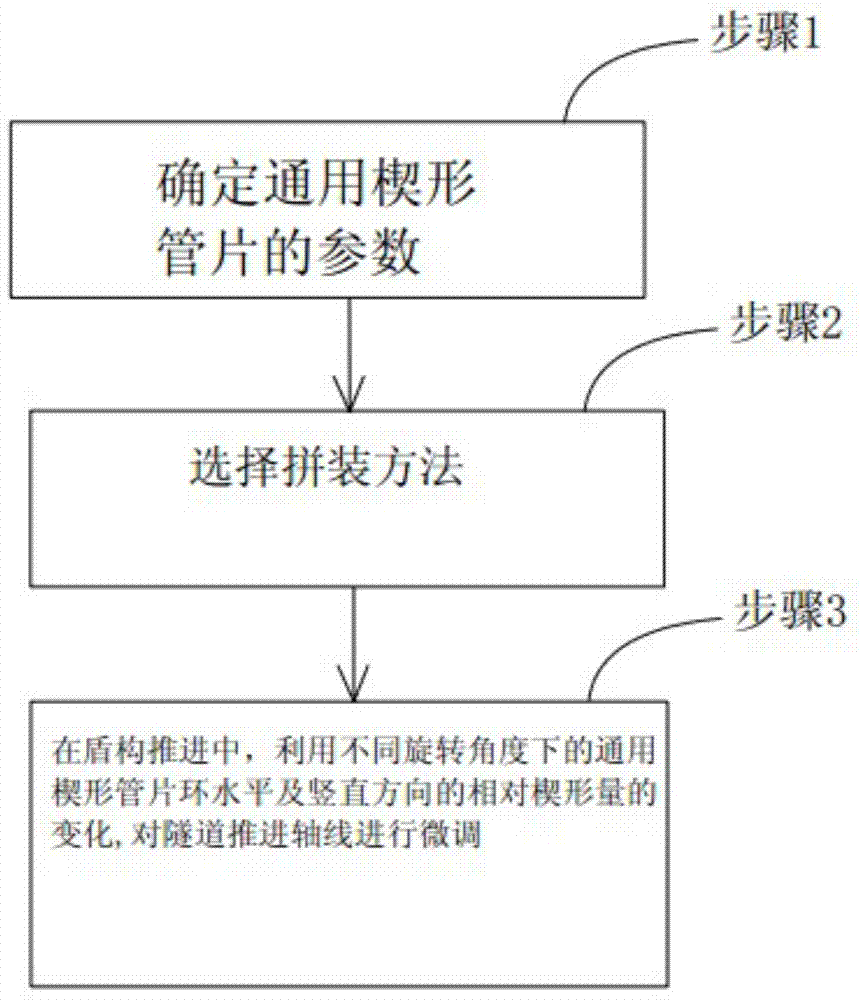

[0016] Such as Figure 1 to Figure 5 As shown, this embodiment provides a general wedge-shaped segment typesetting and assembling method, taking a shield tunnel with a straight line segment and a curved segment with an ultra-small radius of curvature as an example, including the following steps:

[0017] Step 1. According to the total length of the tunnel of this project is 235m, the two ends of the tunnel are straight sections, the design mileage of the middle section is a right-curved small radius section with R=248.5m, the length is 217m, and the lining segment adopts a general wedge-shaped segment. The parameters of segment rings and segments are as follows: segment ring inner diameter is 3900mm, outer diameter is 4460mm, each ring is composed of 6 wedge-shaped segments (A-F), and there are 12 pairs of bolt holes in the longitudinal direction, which are evenly distributed along the circumference of the segment. It is 30° from the center of the segment. Correspondingly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com