Split stator of permanent magnet motor and manufacturing method of split stator

A technology of split stator and permanent magnet motor, which is applied in the manufacture of stator/rotor body, magnetic circuit, electrical components, etc., can solve the problems of difficulty in offline production of stator core manufacturing process, unfavorable long-term reliable operation, and high manufacturing cost. Simple and feasible maintenance, simple offline and assembly processes, and simple manufacturing and assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

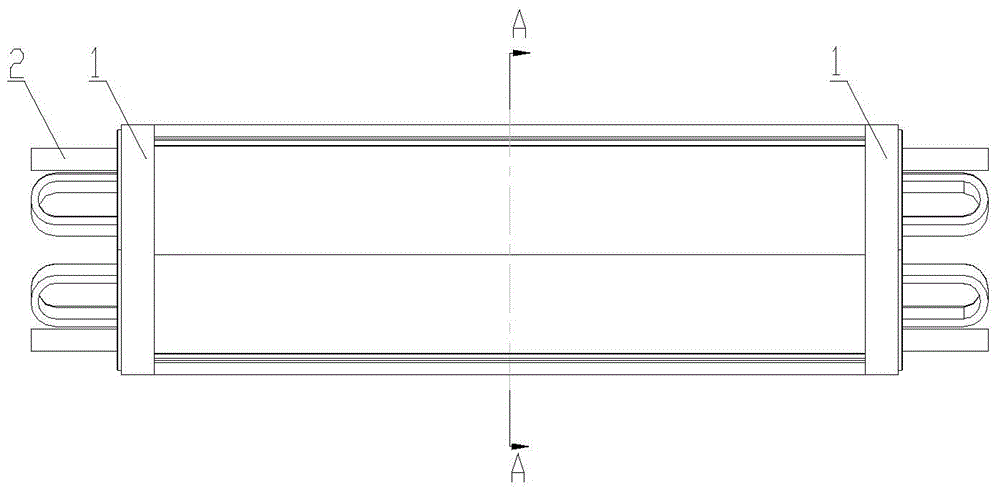

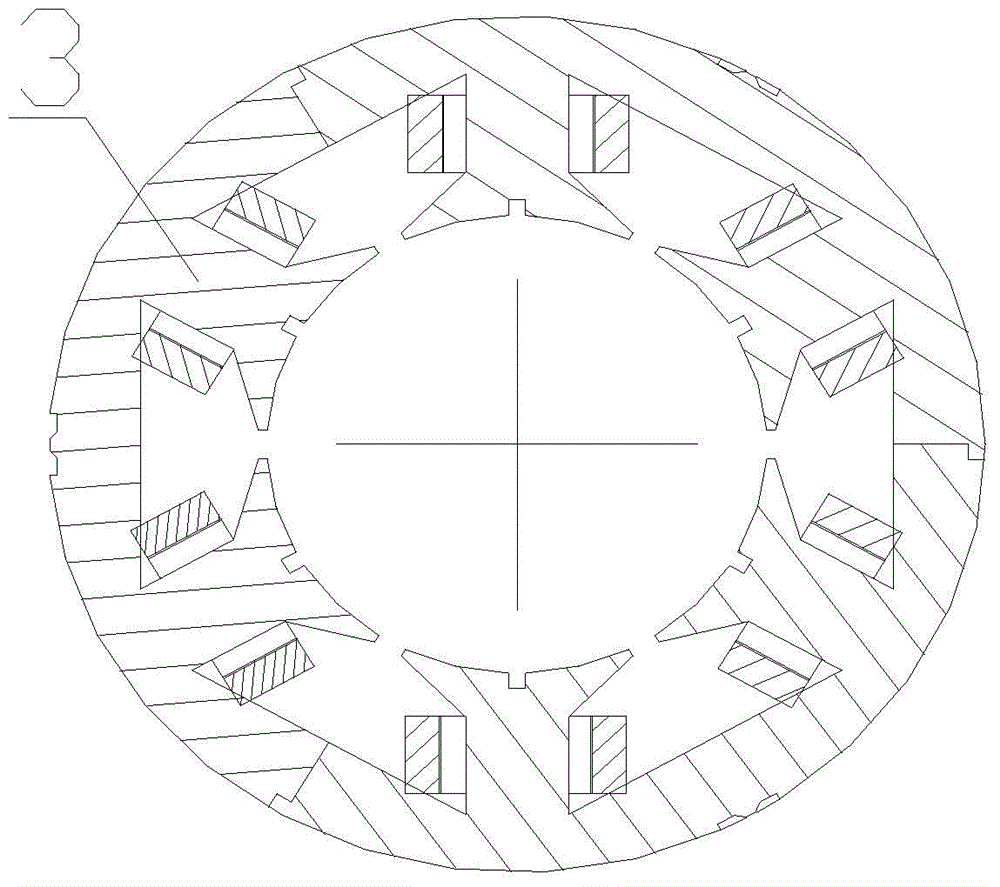

[0025] A split stator of a permanent magnet motor, comprising a split stator core 3 and a coil 2, the coil 2 is wound inside the split stator core 3, and a fastening ring 1, the split stator core 3 is composed of at least three Each petal is assembled with complete teeth, complete slots and half slots; the stator core is tightened by the fastening ring 1; the split stator of the permanent magnet motor is set as a cylinder whose bottom circle diameter is smaller than the length shape.

Embodiment 2

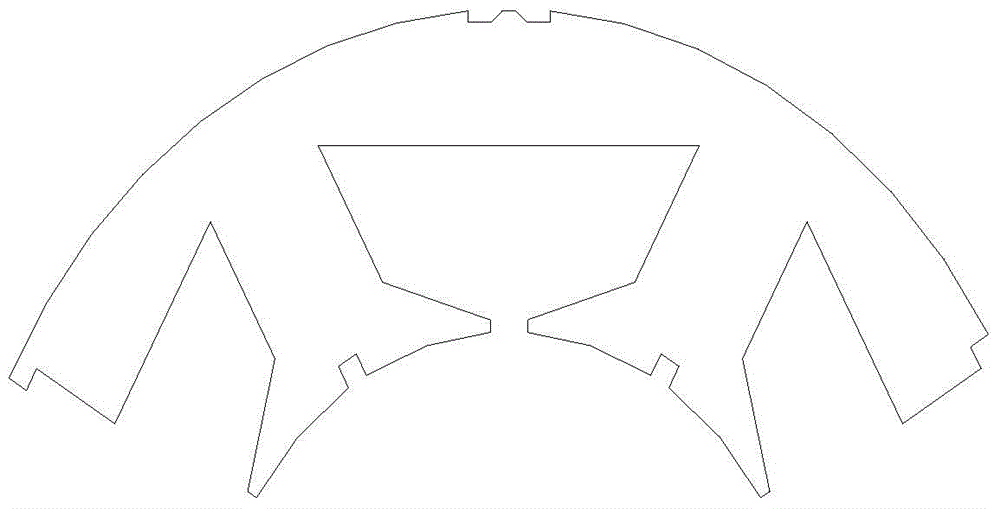

[0027] A split stator of a permanent magnet motor, similar to Embodiment 1, the difference is that the split stator core 3 is composed of three lobes, each lobe is provided with two complete teeth, a complete slot and two half slot; the outside of each lobe of the split stator core 3 is set as an arc-shaped outer circumference of one-third of the circumference, and its inner side is set as an arc-shaped inner circumference of one-third of the circumference concentric with it, and the outer The cross-section formed by the combination of the circumference and the inner circumference is fan-shaped; the outer circumference of each lobe of the split stator core 3 is provided with an inverted "concave" notch; each lobe of the split stator core 3 One end of the outer circumference is provided with an assembly boss, and the other end is provided with a matching assembly groove; the core teeth are provided with a groove at the end of the inner circumference.

Embodiment 3

[0029] A split stator of a permanent magnet motor is similar to Embodiment 2, the difference is that the number of fastening rings 1 is two, which are respectively arranged at the two ends of the split stator core 3 . The aspect ratio of the split stator of the permanent magnet motor, that is, the ratio of the length to the diameter of the bottom circle, is 6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com