A new type of multifunctional auto parts noise test bench

A technology for auto parts and noise testing, applied in the testing of machine/structural components, vehicle testing, vibration testing, etc., can solve the problems of manual collection of data affecting accuracy, poor versatility and adjustability, and high price. Reliable performance, reduced test errors, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0025] The design idea of the present invention is:

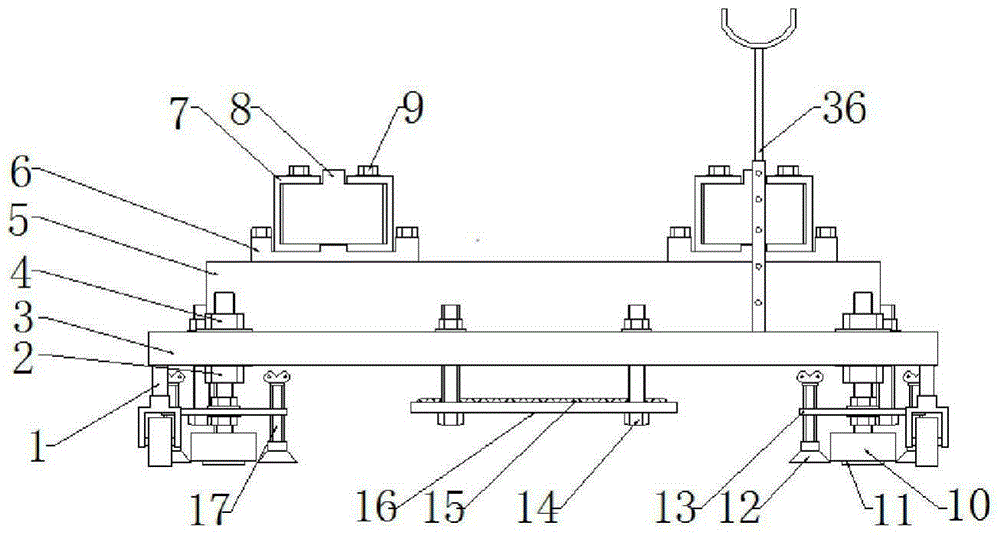

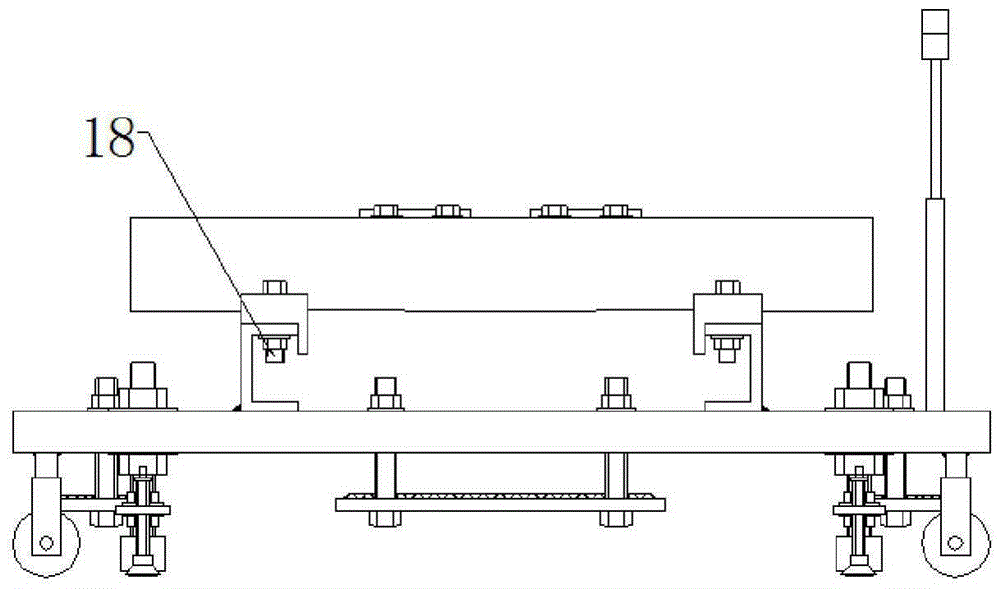

[0026] Design a new type of auto parts new multifunctional auto parts noise test bench, the bench is divided into two parts: main bench and auxiliary test bench.

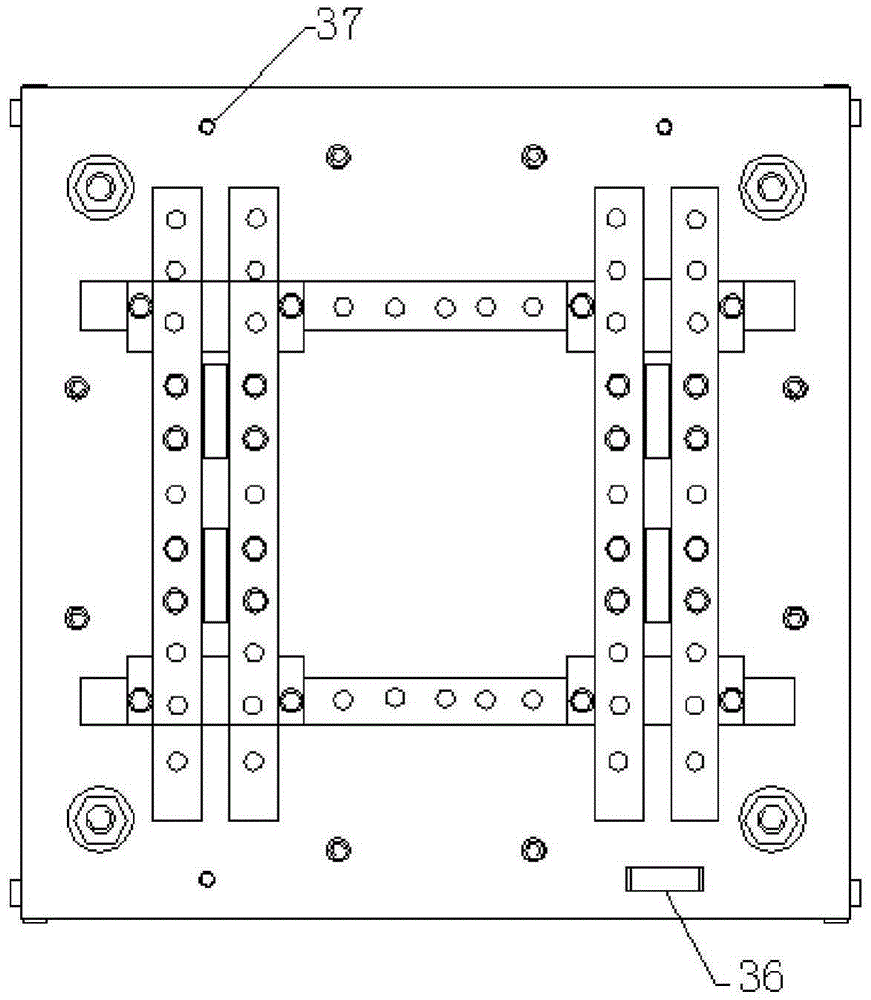

[0027] The main stand is mainly used to install the tested products, such as engines, transmissions, vehicle motors, etc. The stand is installed on a heavy metal base plate with multiple support legs fixed by suction cups to improve product testing time The stability of the whole system will not cause the platform to shift or self-resonate due to vibration. Design a unique structure according to the two positions of the metal plate and the bottom:

[0028] 1. The upper part of the metal plate is designed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com