Cam Tappet Friction Coefficient Measuring Device

A technology of friction coefficient and cam, which is applied in the field of cam tappet friction coefficient measuring device, can solve the problems of no direct measurement of cam and tappet friction, friction coefficient, and no unified test standard, etc., and achieves wide application range, simple structure, The effect of easy wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

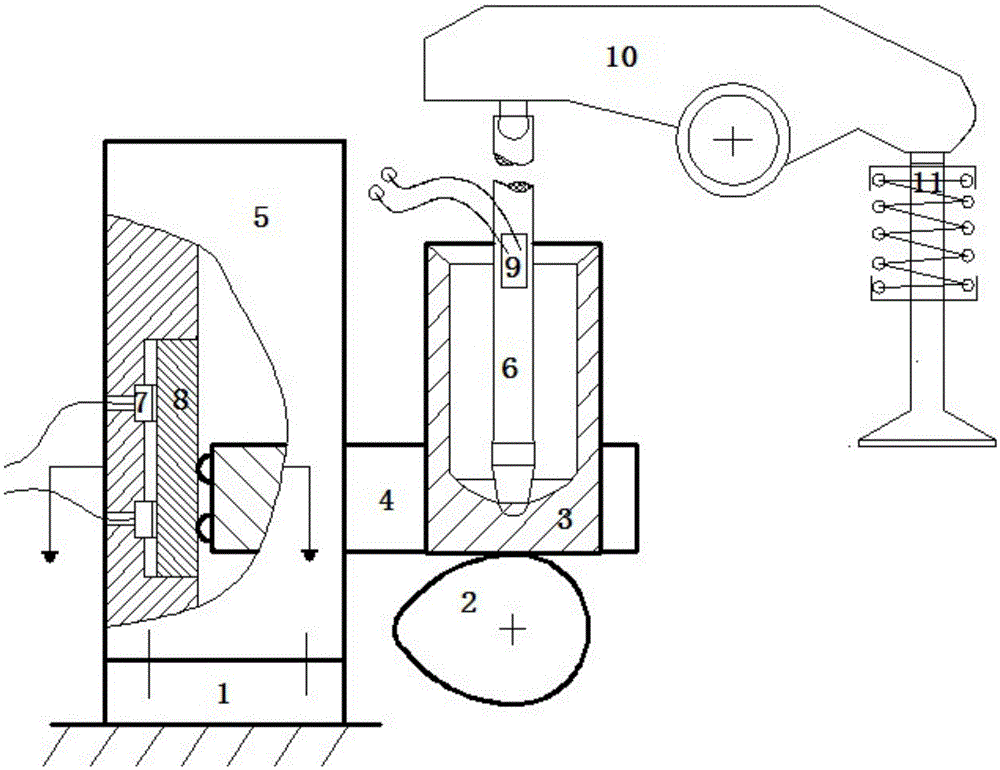

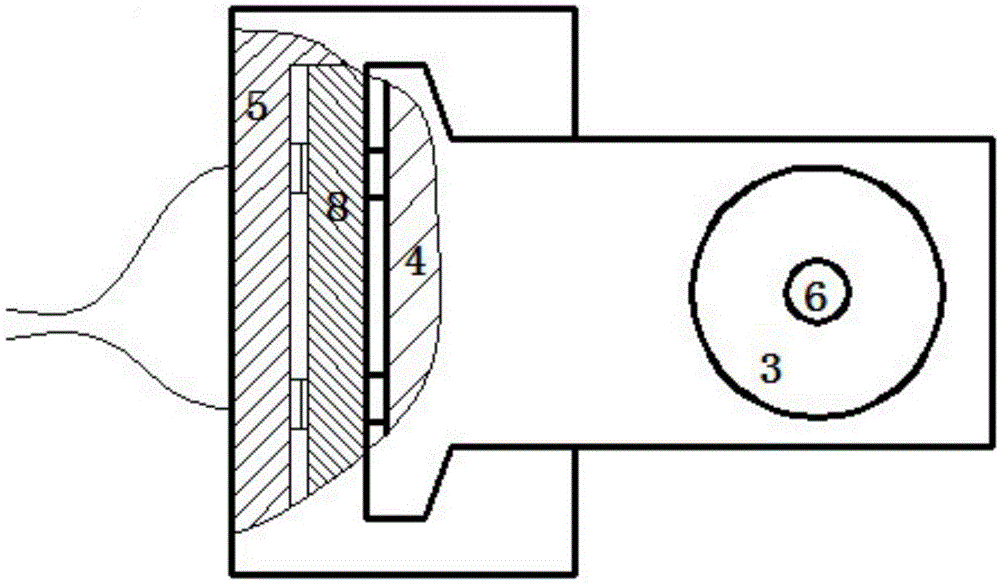

[0018] The test device of the present invention will be further described below in conjunction with the accompanying drawings.

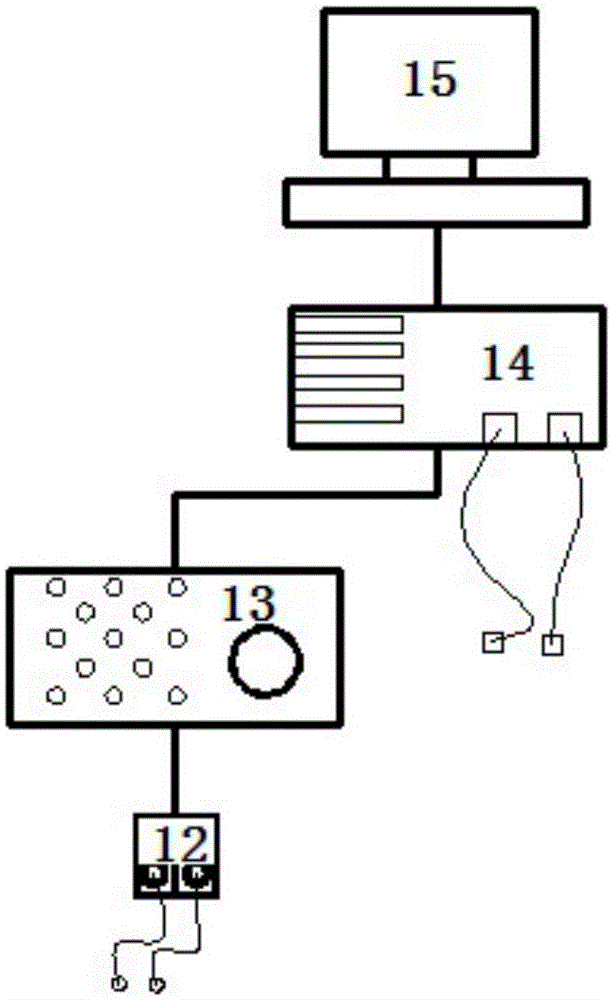

[0019] Such as figure 1 and figure 2 As shown, the slider guide rail 5 is fixed on the test bench 1; the four pressure sensors 7 are adhered to the pressure sensor guide block 8 and installed on the side of the slider guide rail 5; the tappet slider 4 and the tappet 3 are integrated , one end of which cooperates with the slider guide rail 5, and uses four rollers to contact the pressure sensor guide block 8; the resistance strain gauge 9 is attached to the side of the push rod 6. The push rod connects the rocker arm 10 and the valve assembly 11 .

[0020] When the cam 2 rotates, the tappet 3 and the tappet slider 4 move periodically up and down along the slider guide rail 5 . The lower surface of the slider slides relative to the cam, and due to friction, the tappet slider presses to the left toward the guide block 8 of the pressure sensor; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com