Smoothness-characteristic-quantity-based surface gray scale defect detection method for rotary-cut wooden product

A defect detection and smoothness technology, which is applied in the direction of optical defect/defect, image data processing, instrument, etc., can solve the problems of non-contact visual detection method, low degree of automation, low detection efficiency, etc., to overcome missed detection Elimination of misdetection, improved automation, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

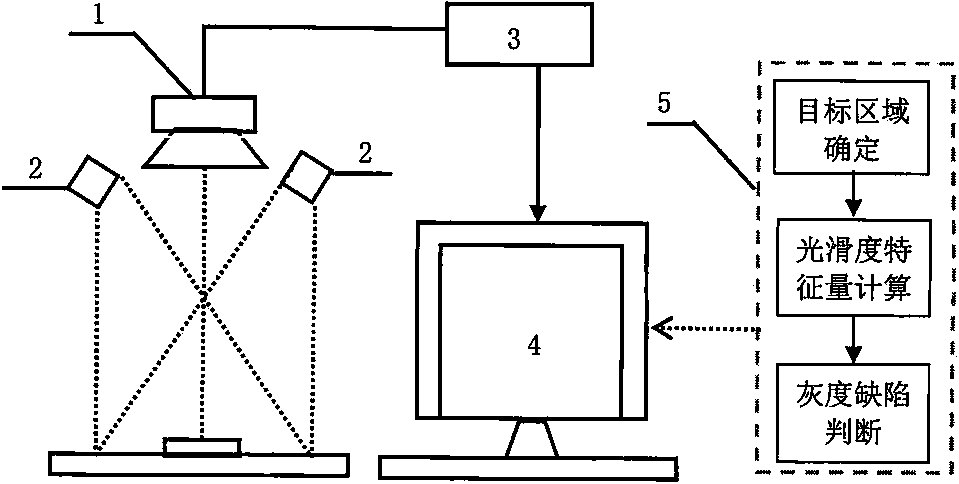

[0037] The specific implementation manner of the present invention is described with reference to the drawings and examples. according to figure 1 Establish a measurement system, including a CCD camera 1, two blue LED strip light sources 2, an image acquisition card 3 and a computer 4; the two light sources 2 are symmetrically arranged and adopt a high-angle lighting method, and the CCD camera 1 is placed The upper position between the two light sources 2; the image acquisition card 3 is connected with the CCD camera 1 and the computer 4 respectively.

[0038] In the actual inspection, when the rotary cut wood products are sequentially conveyed directly under the CCD camera 1 , the CCD camera 1 collects images, and then converts the images into digital images through the image acquisition card 3 and inputs them into the computer 4 . Select 100 pieces of rotary-cut wood products with normal surface and 100 pieces with various grayscale defects on the surface, respectively carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com