A needle-tip discharge device for ablation of solid surface

A discharge device, solid surface technology, applied in the field of elemental analysis in solid samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

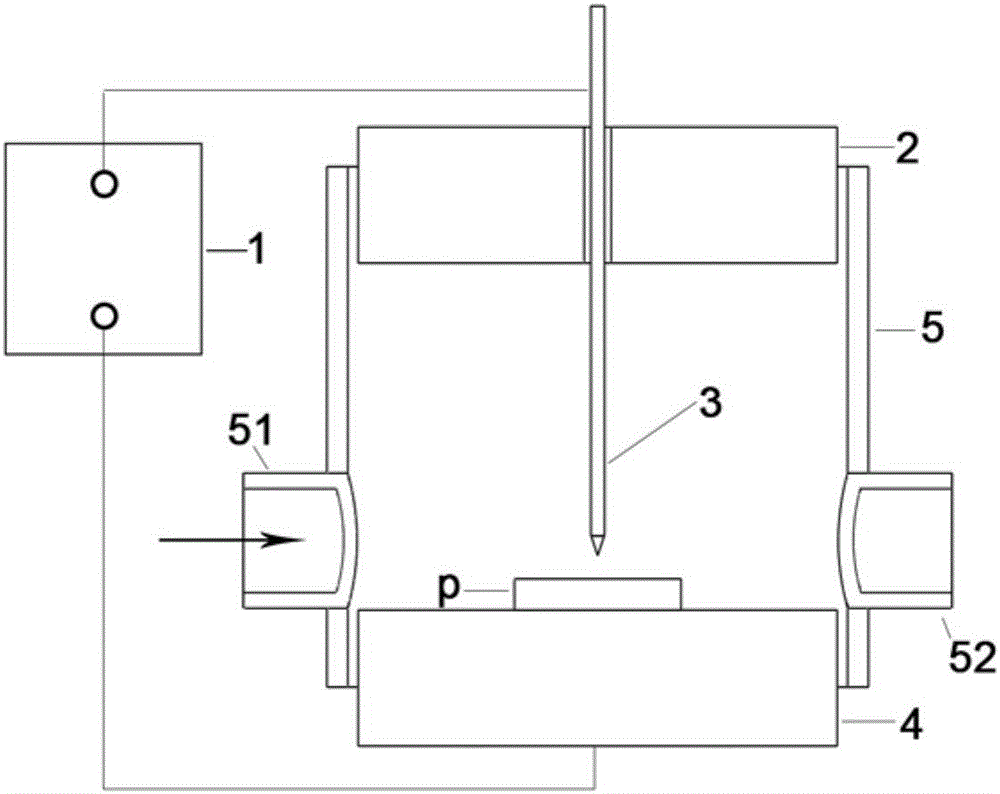

[0027] see figure 1 , the embodiment of the present invention includes a high-voltage power supply 1 (pulse power supply), a needle body support platform 2, a needle body 3, a sample stage 4, a cavity 5 and a working gas.

[0028] The electrodes of the high-voltage power supply 1 are respectively connected to the needle body 3 and the sample stage 4, the needle body support platform 2 is arranged on the upper part of the cavity 5 and is sealed with the cavity 5, and the sample stage 4 is arranged at the lower part of the cavity 5 and is connected with the cavity 5 in a sealed manner , the needle body 3 passes through the needle body support platform 2 and extends into the cavity 5, the needle tip of the needle body 3 faces the surface of the sample table 4, the inside of the cavity 5 is a sealed chamber, and the cavity 5 is provided with an inlet 51 and an outlet of the working gas 52, the arrow represents the air intake direction. The working gas is located in the sealed cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com