Processing method of spherical fine Archimedes spiral based on ug4.0

An Archimedes spiral and wire processing technology, which is applied in the direction of instruments, computer control, simulators, etc., can solve the problem of not being able to meet the fine Archimedes spiral processing of the spherical surface, and achieve good processing effect and smooth edge of the engraved line , Solve the effect of extremely easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

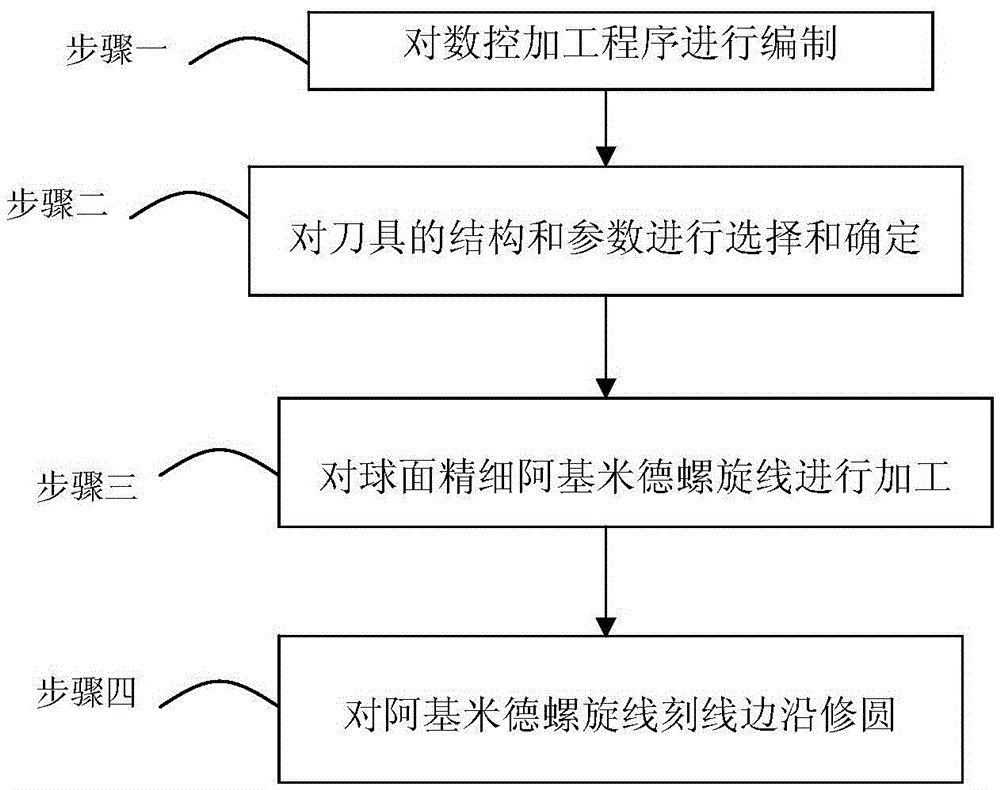

[0022] Specific embodiment 1: The UG4.0-based spherical fine Archimedes spiral processing method of this embodiment includes the following contents:

[0023] 1. Planning the trajectory of the spiral machining tool;

[0024] 2. Select and confirm the structure and parameters of the tool;

[0025] 3. Correct the trajectory of the spiral processing tool in step 1, and then perform fine Archimedes spiral processing on the spherical surface according to the corrected trajectory;

[0026] Fourth, the spherical Archimedes spiral line edge trimming obtained in step 3 completes the spherical fine Archimedes spiral line processing method based on UG4.0.

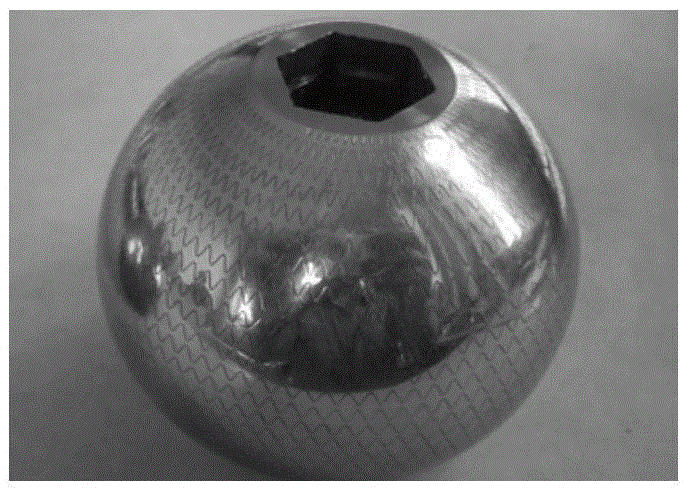

[0027] Effects of this implementation:

[0028] This embodiment adopts Mitterrand's five-axis machining center and uses UG4.0 three-dimensional software to construct a spherical Archimedes through the establishment of three-dimensional spheres, the establishment of the mathematical equations of Archimedes spirals, and the parameterization of sphe...

specific Embodiment approach 2

[0030] Specific embodiment two: This embodiment is different from the specific embodiment one in that the specific process of planning the trajectory of the spiral machining tool in the step one is:

[0031] (1) Establish a sphere model: Set the center of the sphere as the origin of the sphere coordinate system through the UG4.0 software, and perform Boolean operations on the inner hole and end face of the sphere according to the requirements of the drawing to initially complete the establishment of the sphere entity;

[0032] (2) Establishment of spiral line:

[0033] Set the sine curve equation in UG4.0 software:

[0034] theta=t*360

[0035] xt=t

[0036] yt=sin(theta)

[0037] zt=0; where t represents the variable, xt represents the position of the curve on the X axis, yt represents the position of the curve on the Y axis, and zt represents the position of the curve on the Z axis;

[0038] (3) Establish the mathematical equation of Archimedes spiral: Archimedes spiral, when point P mov...

specific Embodiment approach 3

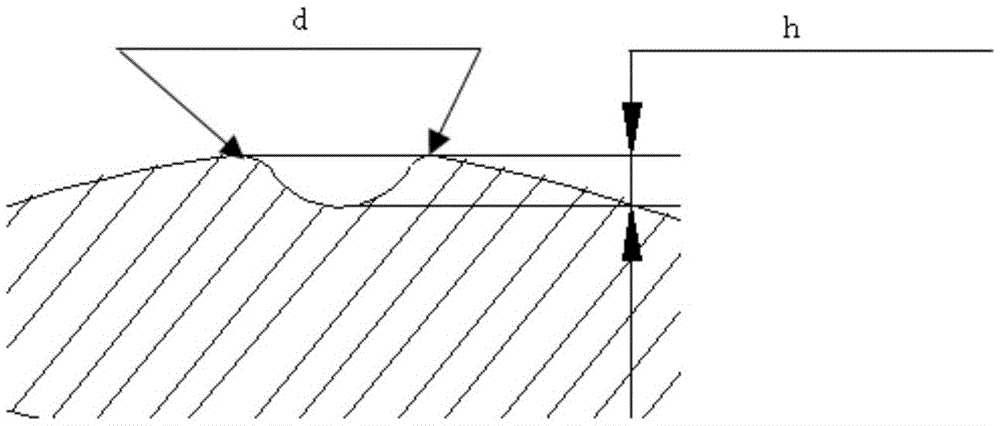

[0068] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the selection and determination of the structure and parameters of the tool in the second step are specifically as follows:

[0069] The tool adopts imported cemented carbide rod material, the tool angle is 55°, the tool nose radius is ≤SR0.05, and a single cutting edge passing through the center is processed at the tool nose. The tool angle is related to the cutting speed of the machine tool. When the machine speed reaches 20,000 rpm / Min, the tool can choose a 30° angle, when the number of revolutions is less than 10000 revolutions / min, the angle of the tool cannot be less than 50°. Other steps and parameters are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com