Worktable speed control method without bending sensor for multi-wire cutting machine

A multi-wire cutting machine, speed control technology, applied in the direction of digital control, electrical program control, etc., to achieve the effect of high slicing efficiency, good surface parallelism, and uniform slicing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

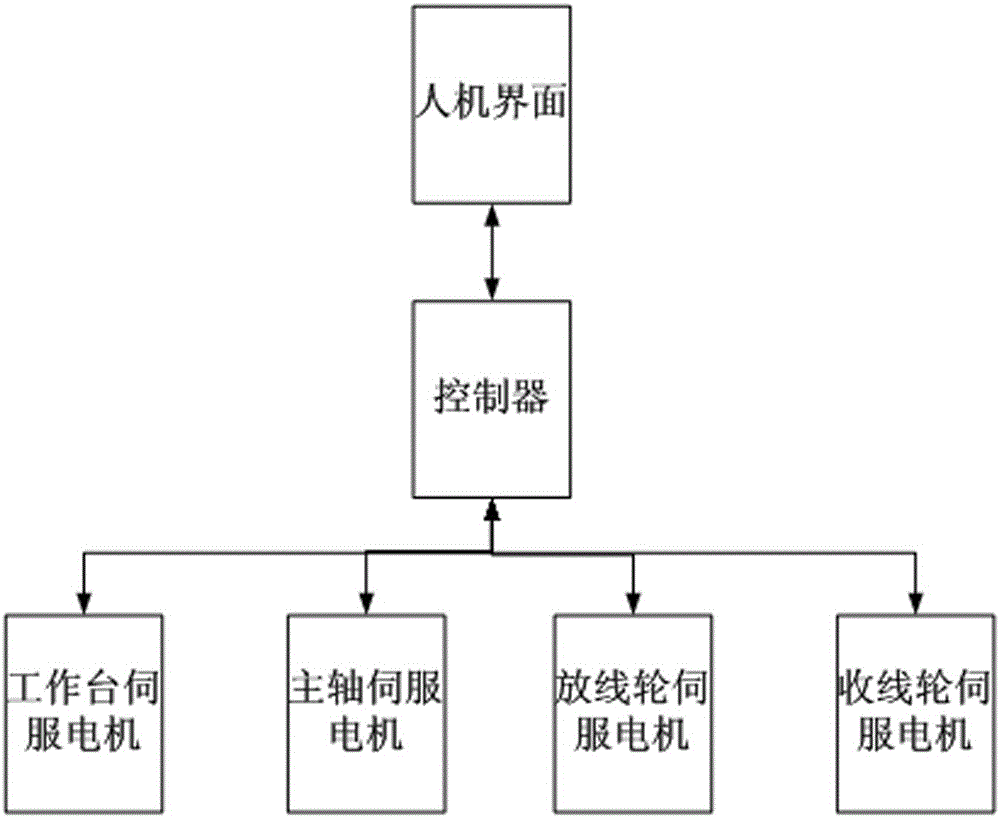

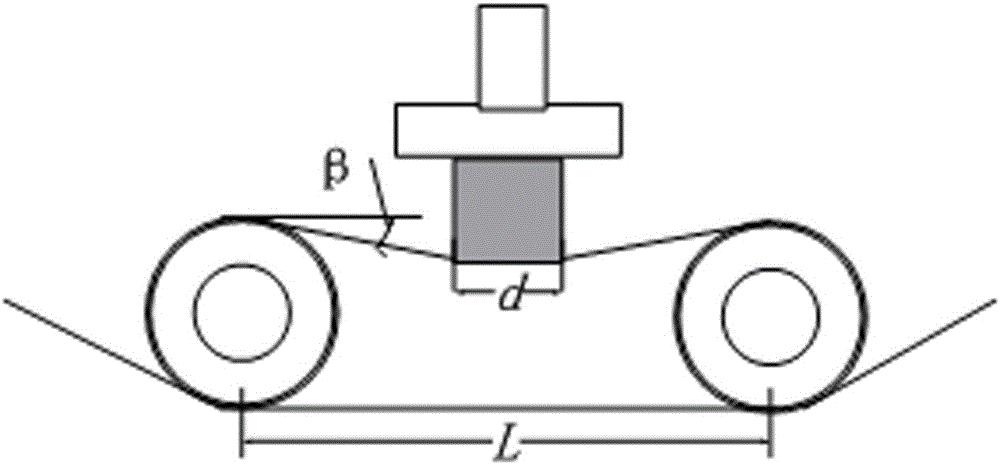

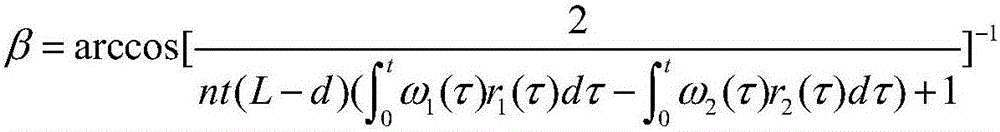

[0020] Such as figure 1 The structure of the sensorless workbench control system is shown, including man-machine interface, controller, workbench servo motor, spindle servo motor, take-up reel servo motor and pay-off reel servo motor. The field bus is used for high-speed transmission between the controller and each servo drive, and the industrial Ethernet communication is used between the man-machine interface and the controller. During operation, the operator first inputs the diameter of the cutting line, the initial diameter of the take-up and take-up reel, the size of the material to be cut, and the number of winding turns of the main shaft to the controller through the man-machine interface. Secondly, input the expected value of the included angle of the cutting surface and the linear speed of the system to the controller through the man-machine interface. The controller calculates the initial angular velocity of the spindle motor and the take-up and take-up line motor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com