Exhaust safety valve for lead-acid storage battery and production process thereof

A lead-acid battery and production process technology, applied in the direction of lead-acid batteries, electrical components, battery components, etc., can solve the problems of battery pack failure and poor product performance consistency, and achieve the goal of improving product performance and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

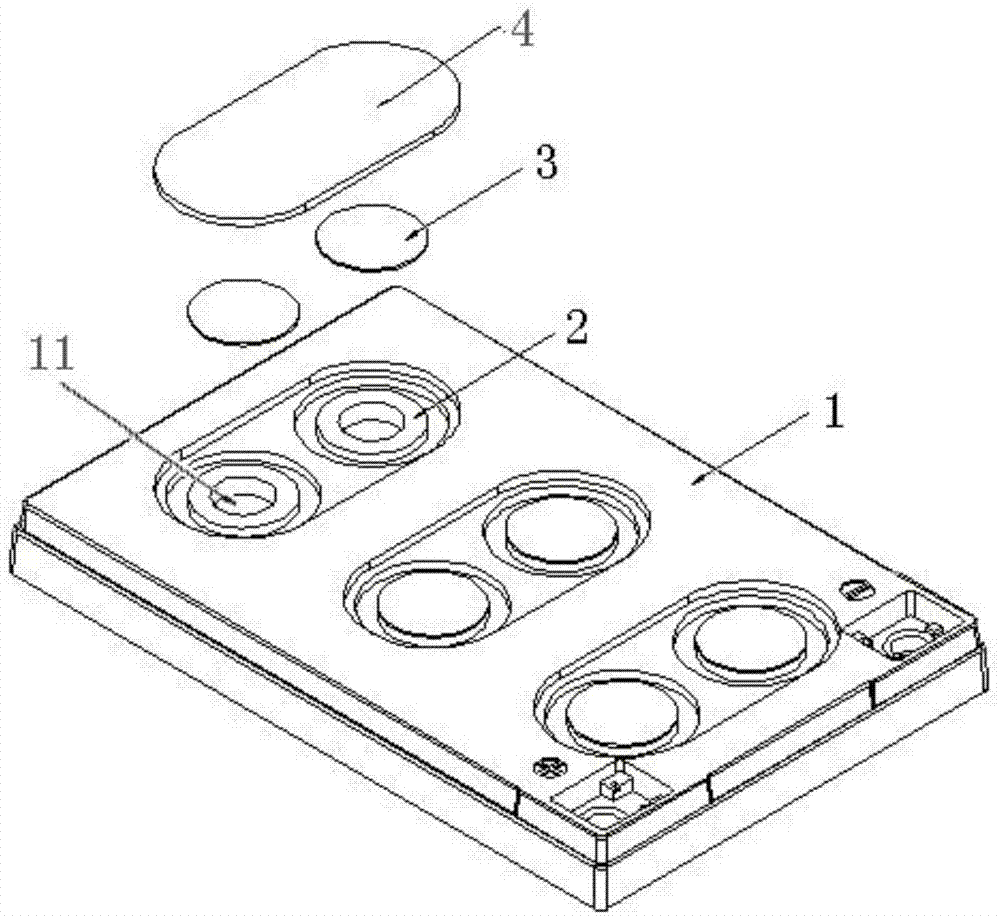

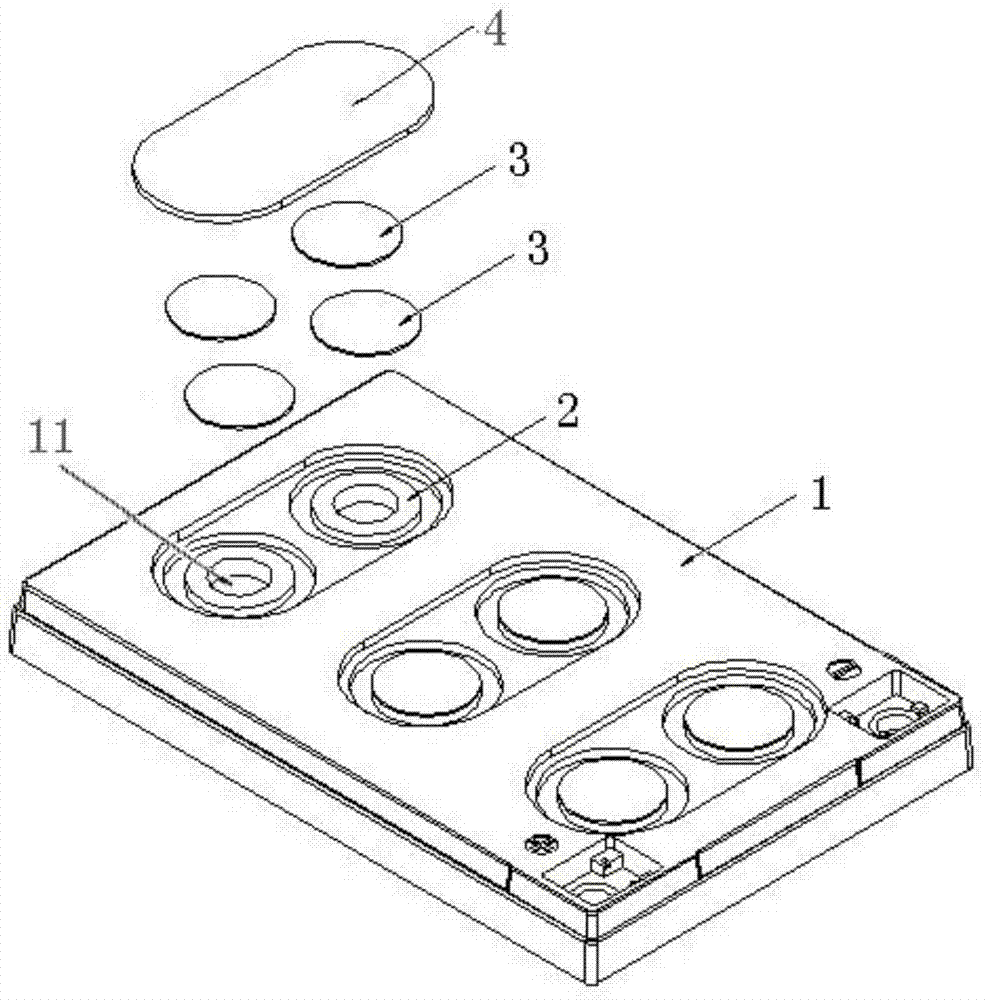

[0020] Such as Figures 1 to 2 As shown, it is an embodiment 1 of a lead-acid battery exhaust safety valve of the present invention, including an ultrasonic welding ring 2 and a pressure compensation film 3, and the ultrasonic welding ring 2 is installed on the safety valve of the lead-acid battery upper cover 1 The edge of the port 11, the pressure compensation film 3 covers the safety valve port 11 and is welded with the ultrasonic welding ring 2. Compared with the existing technology, the existing safety valve seat is canceled and the ultrasonic welding ring 2 is added, such as the 6-DZM-12 type battery, which saves 6-10mm of space in height and improves the effective use of battery space by 5%- 8%, at the same time, to facilitate the installation of the exhaust safety valve, the cover piece 4 is welded on the top of the pressure compensation film 3.

[0021] The pressure compensation film 3 is an expanded polytetrafluoroethylene film. Expanded polytetrafluoroethylene mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap