Columnar giant magnetostrictive telescopic energy harvester

A technology of giant magnetostriction and giant magnetostrictive rods, which is applied in the direction of piezoelectric effect/electrostriction or magnetostriction motors, electrical components, generators/motors, etc., and can solve the low conversion efficiency of vibration energy capture devices etc. to achieve the effects of light weight, long service life and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

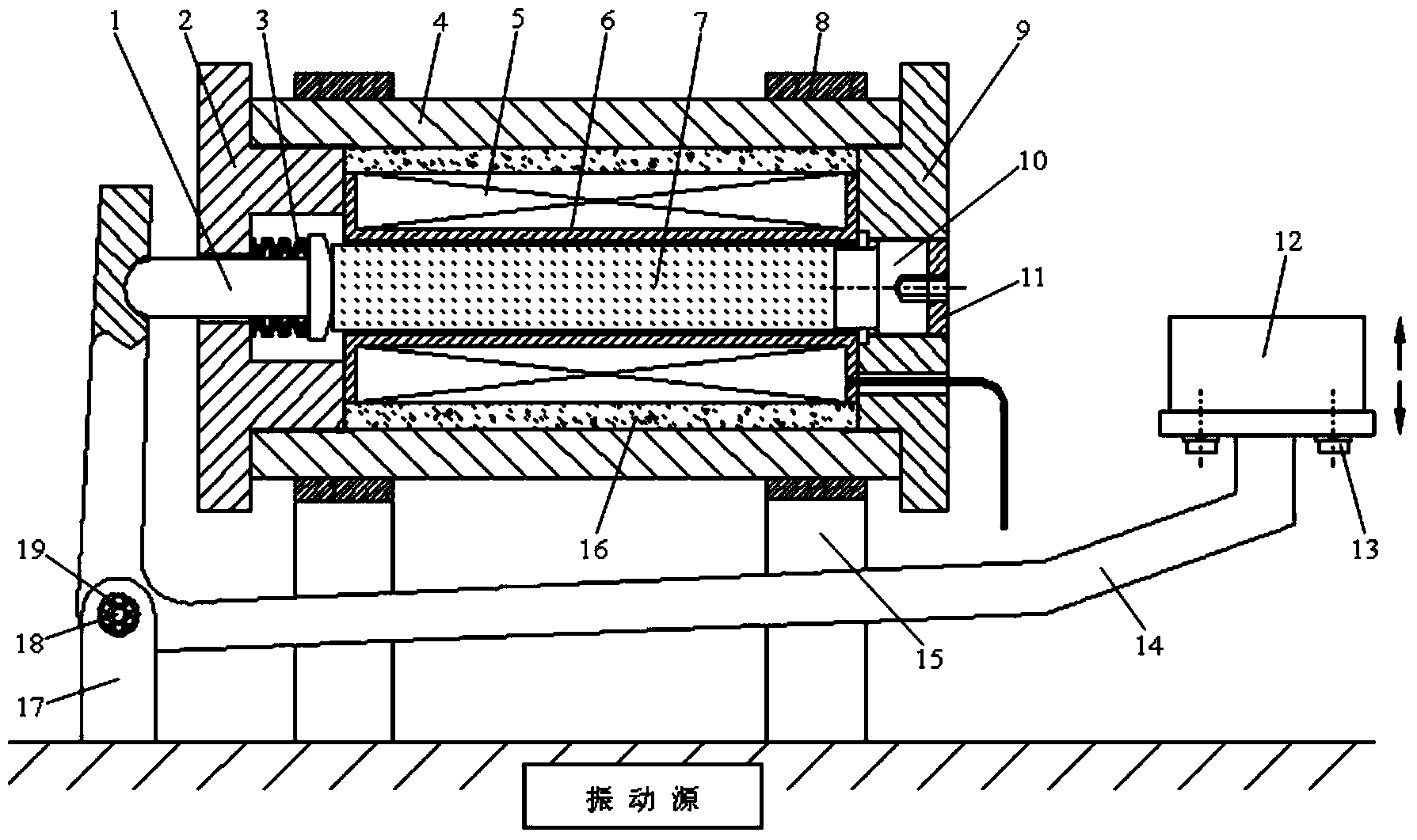

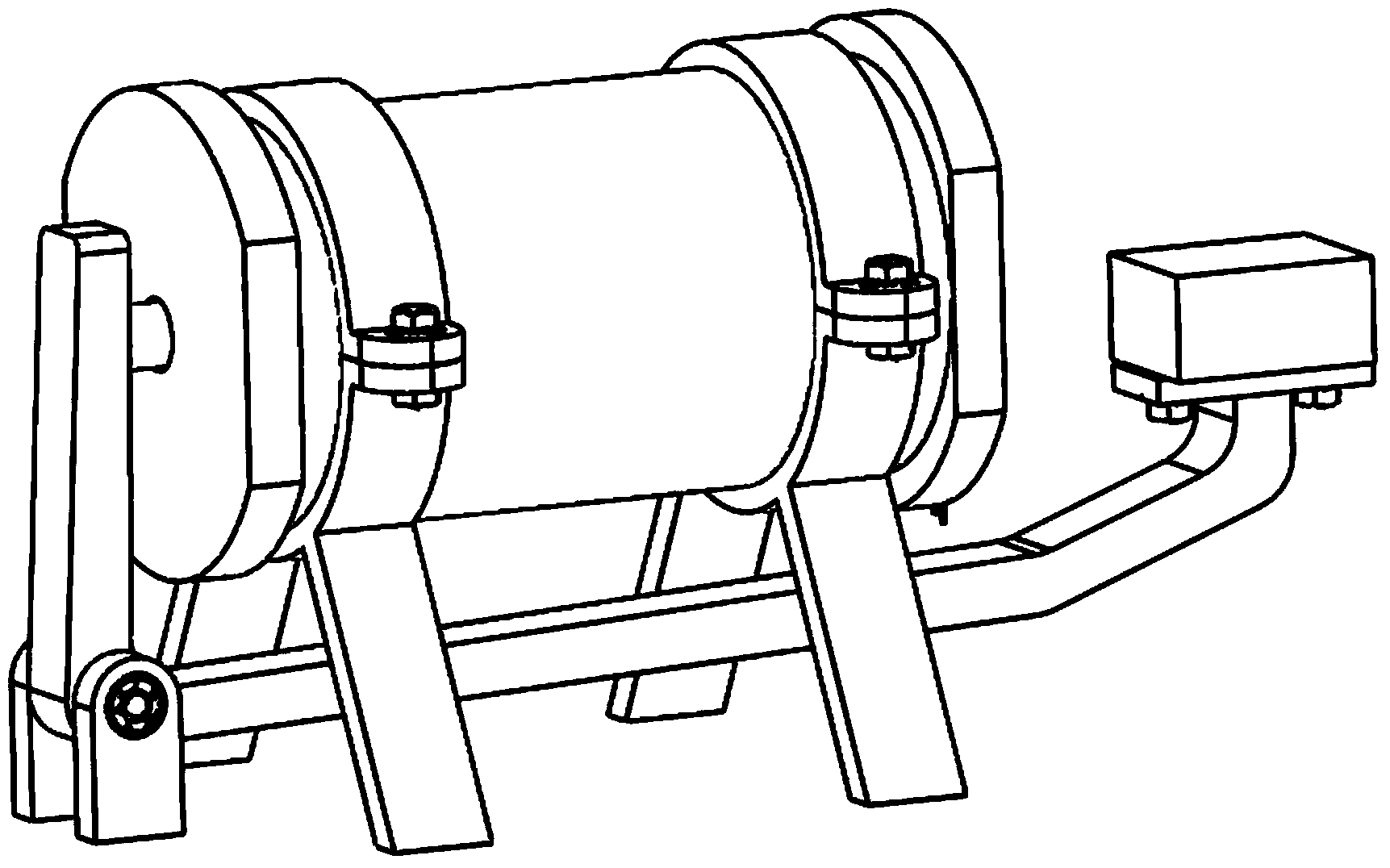

[0017] The columnar giant magnetostrictive energy harvester suitable for collecting energy from low-amplitude excitation described in the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0018] like figure 1 As shown, the columnar giant magnetostrictive energy harvester includes input ejector rod 1, upper end cover 2, butterfly spring 3, cylindrical shell 4, induction coil 5, coil bobbin 6, giant magnetostrictive rod 7, U-shaped Upper bracket 8, lower end cover 9, adjusting screw 10, anti-loosening screw 11, counterweight 12, screw 13, L-shaped lever 14, U-shaped lower bracket 15, permanent magnet 16, hinge support 17, support shaft 18, bearing 19. It is characterized in that: counterweight 12, screw 13, L-shaped lever 14, hinge support 17, support shaft 18, and bearing 19 form a vibration-picking amplification mechanism, wherein L-shaped lever 14 is installed on the hinge support through support sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap