Flavor tea fish sausage and processing method thereof

A technology for flavored tea fish sausage and tea fish, which is applied in the field of sausage and can solve the problems of high price and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

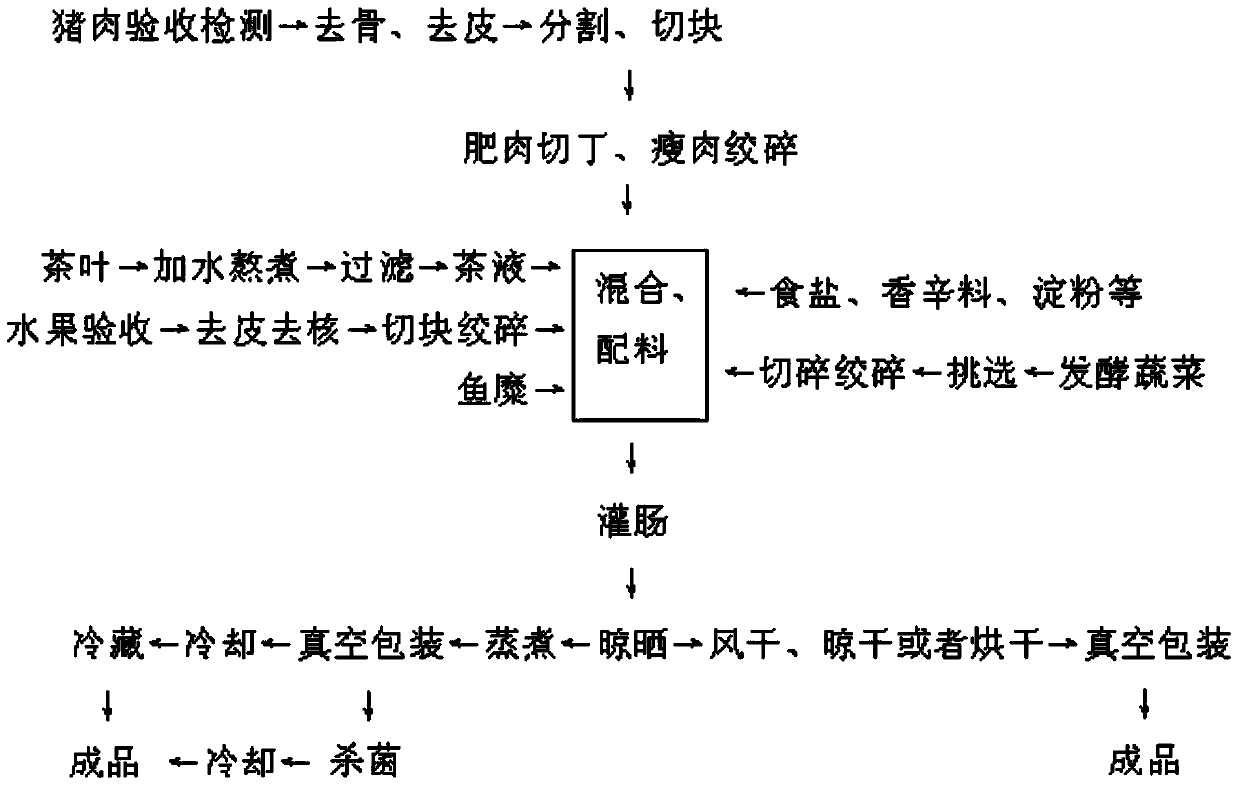

[0086] The processing flow of flavor tea fish sausage is as follows: figure 1 As shown, the specific steps are as follows:

[0087] (1) Preparation of tea liquid: Take tea leaves and add water with 16 times the mass of tea leaves, boil and continue to boil. When the remaining juice is about 5 times the mass of tea leaves, filter to remove slag to obtain tea liquid;

[0088] (2) Selection and processing of fermented vegetables Select salted and fermented plum vegetables and grandma vegetables, then mix the plum vegetables and grandma vegetables in equal amounts, chop them finely and mince them;

[0089] (3) Processing of spices

[0090] The spice formula is calculated by mass percentage, cinnamon 17%, cardamom 17%, tangerine peel 8%, pepper 12%, Codonopsis 12%, star anise 12%, cumin 15%, astragalus 7%;

[0091] Accurately weigh, wash, dry and mix the above ingredients evenly, then crush them appropriately, add water 40 times the weight of the ingredients, boil and boil until ...

Embodiment 2

[0103] The processing flow of flavor tea fish sausage is as follows: figure 1 As shown, the specific steps are as follows:

[0104] (1) Preparation of tea liquid: Take tea leaves and add water with 19 times the mass of tea leaves, boil and continue to boil. When the remaining juice is about 5 times the mass of tea leaves, filter to remove slag to obtain tea liquid;

[0105] (2) Selection and treatment of fruits. Fresh, pest-free and rotten pineapples, apples and bananas are selected as raw materials. After the raw materials are checked and accepted, they are cleaned. Then, the pineapples and apples are peeled and cut into pieces and blanched in boiling water for 1.5 minutes. Finally, mince or beat the bananas, peel the bananas and blanch them in boiling water for 2.2 minutes before mincing or beating; then mix the pineapple, apple and banana pulp and mud in equal amounts;

[0106] (3) Processing of spices

[0107] The spice formula is calculated by mass percentage, cinnamon ...

Embodiment 3

[0120] The processing flow of flavor tea fish sausage is as follows: figure 1 As shown, the specific steps are as follows:

[0121] (1) Preparation of tea liquid Take tea leaves and water with 18 times the quality of tea leaves, heat and extract in microwave at 65°C twice for 1 hour, filter to obtain tea liquid, combine the tea liquid extracted twice, and concentrate the tea liquid to about 5% of the tea quality. times;

[0122] (2) Selection and treatment of fruits Fresh, pest-free and rotten pineapples and bananas are selected as raw materials. After the raw materials are checked and accepted, they are cleaned. Then, the pineapples are peeled and cut into pieces, blanched in boiling water for 1 minute, and then minced or beaten. After peeling the bananas, blanching them in boiling water for 3 minutes, then mincing or beating; then mixing 40% pineapple and 60% bananas by mass to make flavored tea sausages;

[0123] (3) Selection and processing of fermented vegetables Select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com