Whole-packet tobacco leaf charging and loosening method

A tobacco leaf and loosening technology is applied in the field of tobacco leaf whole pack feeding and loosening treatment, which can solve the problems of inability to guarantee the consistency of tobacco leaf processing characteristics, increase the aroma loss of tobacco leaf raw materials, affect the quality of tobacco leaf redrying, etc. The effect of low crushing rate and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

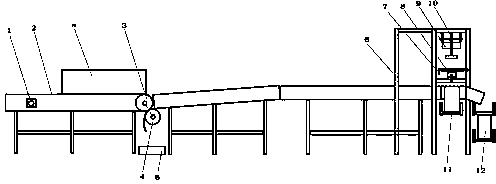

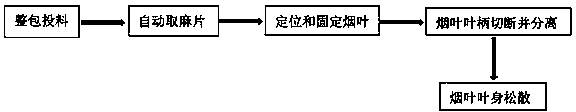

[0023] (1) The incoming tobacco leaves are loose leaves that are aligned with petioles, molded, and sewed and packaged with hemp sheets. The whole cigarette pack is placed on the operating table, and the burlap bag is manually dismantled. Between the bottom of the driving roller of the conveyor belt and the pressing roller, as the entire cigarette package is conveyed forward, the whole piece of hemp is brought out with the rotation of the roller, and the hemp and tobacco leaves are completely separated;

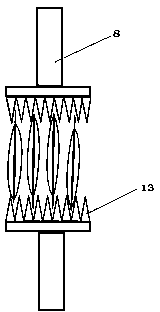

[0024] (2) The cigarette bales that have been unloaded with hemp flakes continue to be conveyed forward with the conveyor belt, and stop at the cutting machine position, and the cylinder baffles on the left and right sides of the conveyor belt are pushed inward to position and fix the tobacco leaves. The upper hanging cylinder baffle is pressed down to fix the tobacco leaves raised upwards, and then the hydraulic cutter cuts off and separates the tobacco leaf stalks;

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com