Cleaning device and cleaning method used in microfiltration process

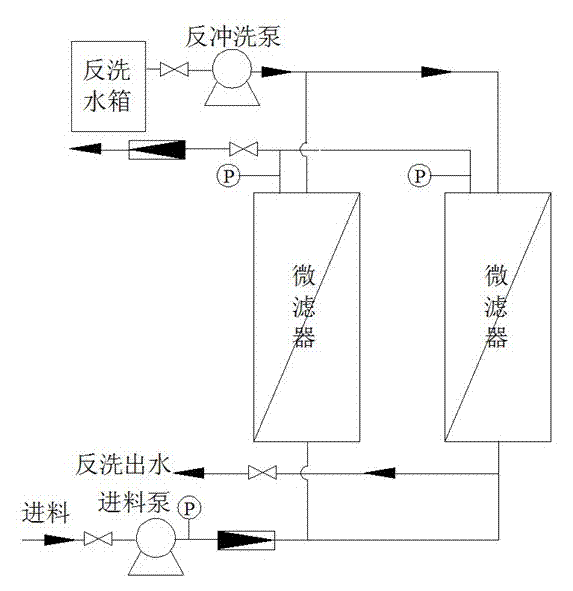

A cleaning device and microfiltration technology, applied in the field of membrane cleaning, can solve the problems of high flow rate of microfiltration backwash pump, discontinuous microfiltration water production, low pump utilization rate, etc., to achieve reliable implementation, save energy and resources, reduce Effect of Equipment Costs and Maintenance Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

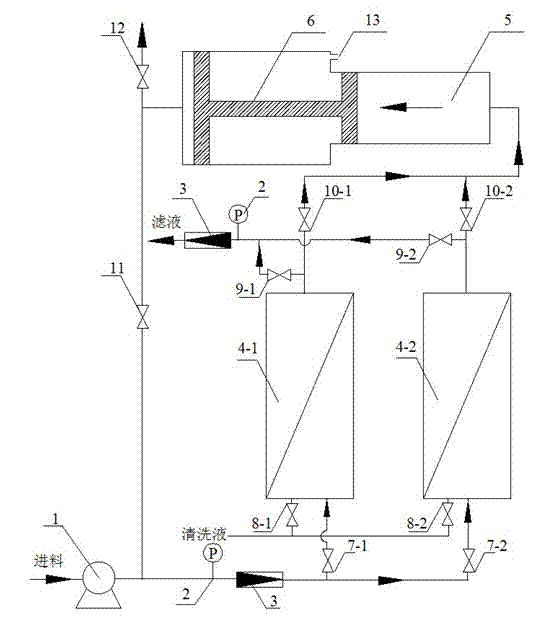

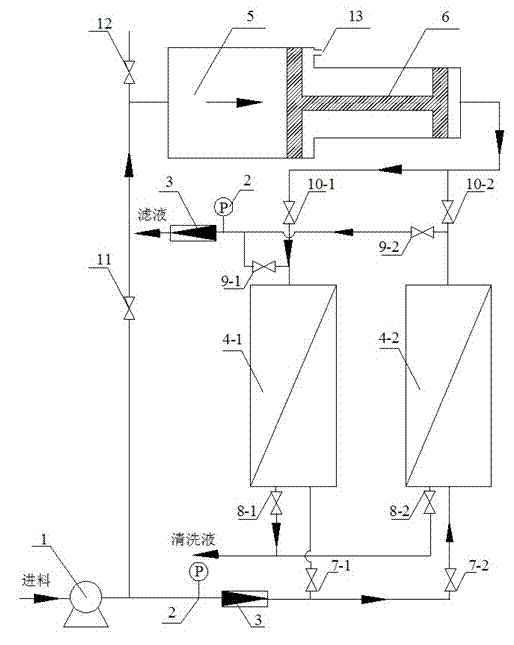

[0021] Attached below figure 2 And attached image 3 The present invention is described in further detail. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0022] The two microfiltration membranes used in this example are polyvinylidene fluoride MOF-910 microfiltration membrane modules. The external dimensions of each microfiltration membrane are φ 90mm×1106mm, and the separation pore size of the microfiltration membrane is 0.2 μm. The cylinder body of the fluid switching cylinder is a glass fiber reinforced plastic body, the outer dimension of the large cylinder is φ 150mm×1000mm, and the outer dimension of the small cylinder is φ 100mm×1000mm. The model of the feed pump is 25YW8-22-1.1, and the switching valves installed on the pipelines are solenoid valves.

[0023] The process of using the above device to microfilter the secondary effluent of sewage is: the pretreated sewage (equivalent to ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com