Ceramic surface simulation natural treatment process

A technology of ceramic surface and processing technology, which is applied in the direction of imitating natural patterns, decorative arts, special patterns, etc., can solve the problems of insufficient color of ceramic inkjet technology, high cost of engraving silicone rollers, and bulky trial production, etc., to achieve Better simulation effect, rich color, and rich texture changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with the best embodiments.

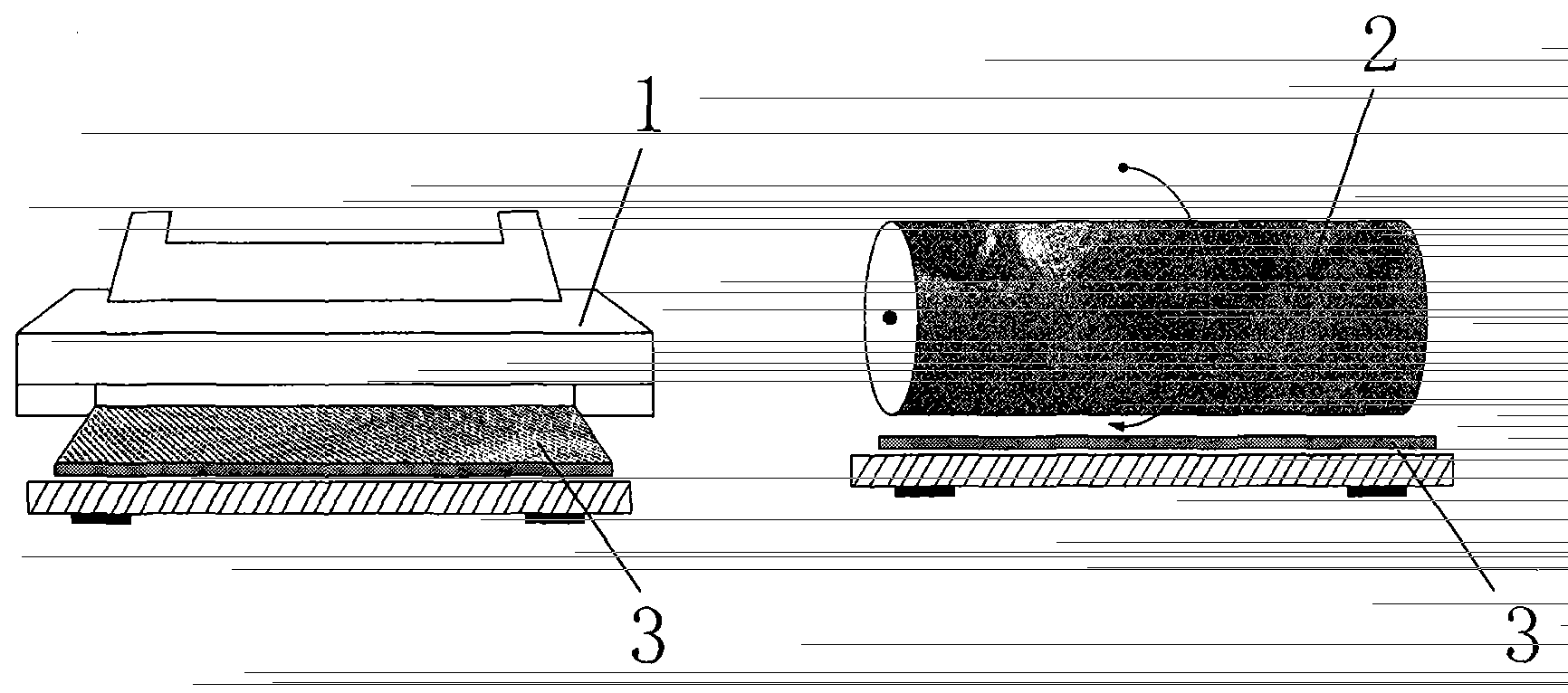

[0012] refer to figure 1 , In this implementation, a ceramic surface simulation natural treatment process, the process of the technology is as follows: the first preparation step, with layout color, prepare the ICC curve (color setting parameter) of the ceramic inkjet machine (1). In the second preparation step, the silica gel surface of the printing roller (2) is engraved by a laser engraving machine to form printing cells and fill glaze. In the third preparation step, the ceramic tile (3) is formed into the target pattern through the first preparation step and the second preparation step. In the fourth preparation step, the products completed in the first three steps are fired.

[0013] In the first preparation step, the technology of the ceramic inkjet machine (1) should be given priority to the color of the layout.

[0014] The required parameters of the printing roller (2) for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com