Large train crane pipe loading metering system

A metering system and crane tube technology, applied in packaging, distribution devices, transportation and packaging, etc., can solve the problems of low automation level and measurement accuracy, large manual workload, and difficult measurement methods, so as to improve the automation level and accuracy, good economic and social benefits, and the effect of improving accuracy and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

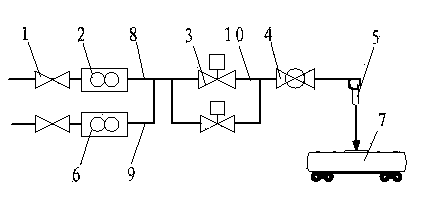

[0015] The present invention train big crane tube loading metering system such as figure 1 As shown, it includes naphtha pipeline 8, gasoline pipeline 9, oil delivery main pipe 10, naphtha flowmeter 2, gasoline flowmeter 6, loading valve 3, shut-off valve 4 and crane pipe 5, and loading valve The shut-off valve is located in the main oil pipeline, the naphtha pipeline and the gasoline pipeline are installed in parallel, and valves 1 are respectively provided. The naphtha flowmeter 2 is installed on the naphtha pipeline, the gasoline flowmeter 6 is installed on the gasoline pipeline, and the gasoline flowmeter 6 is located on the ground. The purpose of installing the gasoline flowmeter on the ground is to increase the back pressure of the flowmeter and improve the measurement accuracy. The loading metering system of Dahe Pipe is controlled by the DCS control unit, and the DCS control unit is equipped with a communication card. The flowmeter pulse signal is used for quantitati...

Embodiment 2

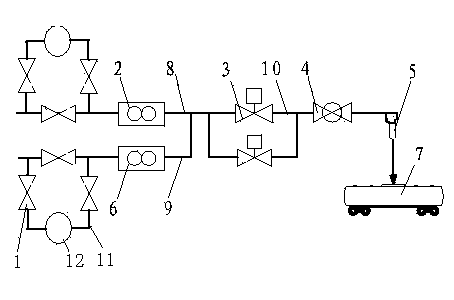

[0020] Another embodiment of the present invention is as figure 2 As shown, the gasoline pipeline 9 and the naphtha pipeline 8 are respectively provided with a bypass 11, and a calibration flowmeter 12 is installed in the bypass. The calibration flowmeter is a 0.05 grade standard mass flowmeter, and a valve 1 is provided at the inlet and outlet of the calibration flowmeter. The "Mobile Coriolis Mass Flowmeter Verification / Calibration Device" is composed of a 0.05-grade standard mass flowmeter, in accordance with JJG 643 "Standard Meter Method Flow Standard Device Verification Regulations", GB / T 17286 "Liquid Hydrocarbon Dynamic Measurement Volume Measurement Verification" System" for online calibration. Calibrate the flowmeter 12 to calibrate the gasoline flowmeter 6 online, so that the parameters of the flowmeter can be adjusted in time, and the accuracy and measurement stability of the flowmeter can be improved. Others are the same as in Example 1. The oil delivery main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com