Method for preparing large granular chloramine T based on cooling crystallization

A technology of cooling crystallization and large particles, which is applied in the field of medicine, can solve the problems of small particle size, and achieve the effects of improved purity, simple operation, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing large particle chloramine T based on cooling crystallization, comprising the following steps:

[0027] (1) Weigh 35g of chloramine T, add it to 140mL ethanol aqueous solution (the volume ratio of ethanol and water in the ethanol aqueous solution is 8:1), heat to 40°C, and stir to dissolve;

[0028] (2) Pour into a jacketed reactor with controllable stirring, stir at 200rpm, cool the solution obtained in step (1) until crystallization is cloudy, and add 0.175g chloramine T crystal to the cloudy solution at 35°C Seed, grow the crystal for 40 minutes, gradually increase the cooling rate, and drop it to 12°C in 3 hours to obtain a crystal suspension;

[0029] (3) Suction filter the crystal suspension obtained in step (2) under reduced pressure, and dry naturally to obtain large particles of chloramine T. The yield is 70%.

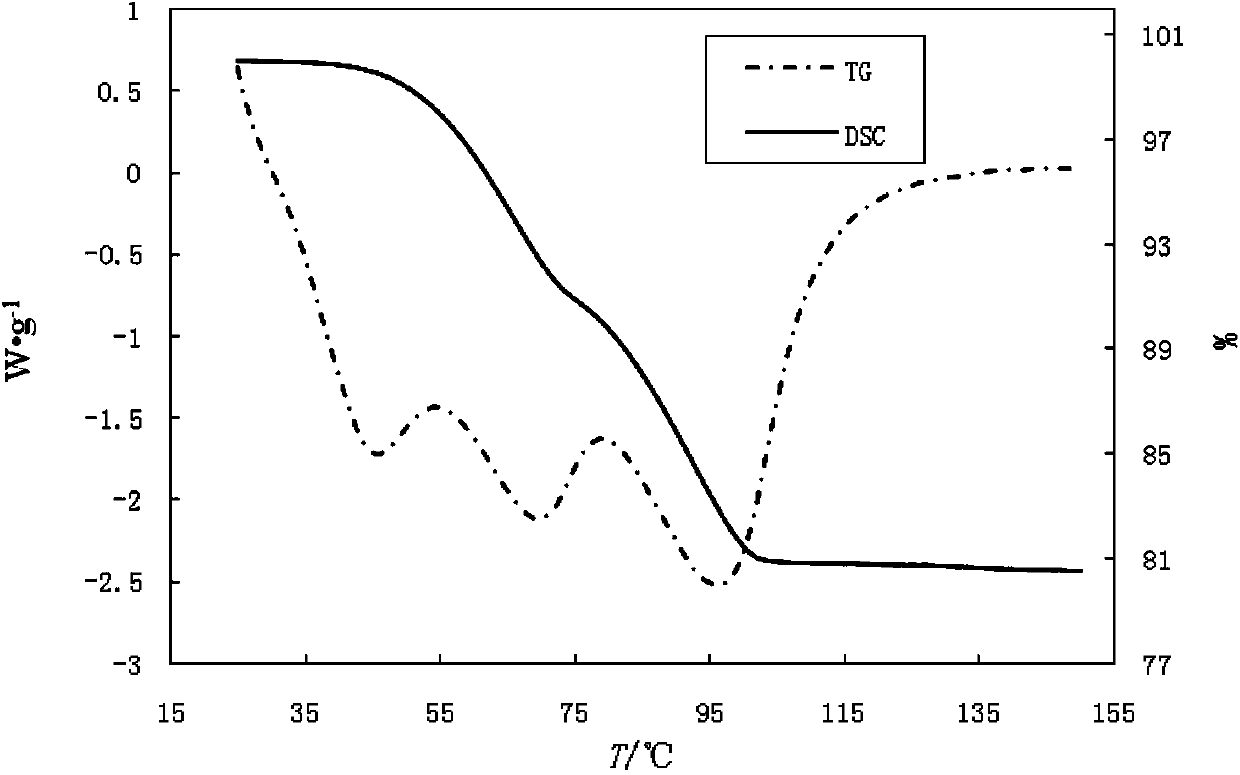

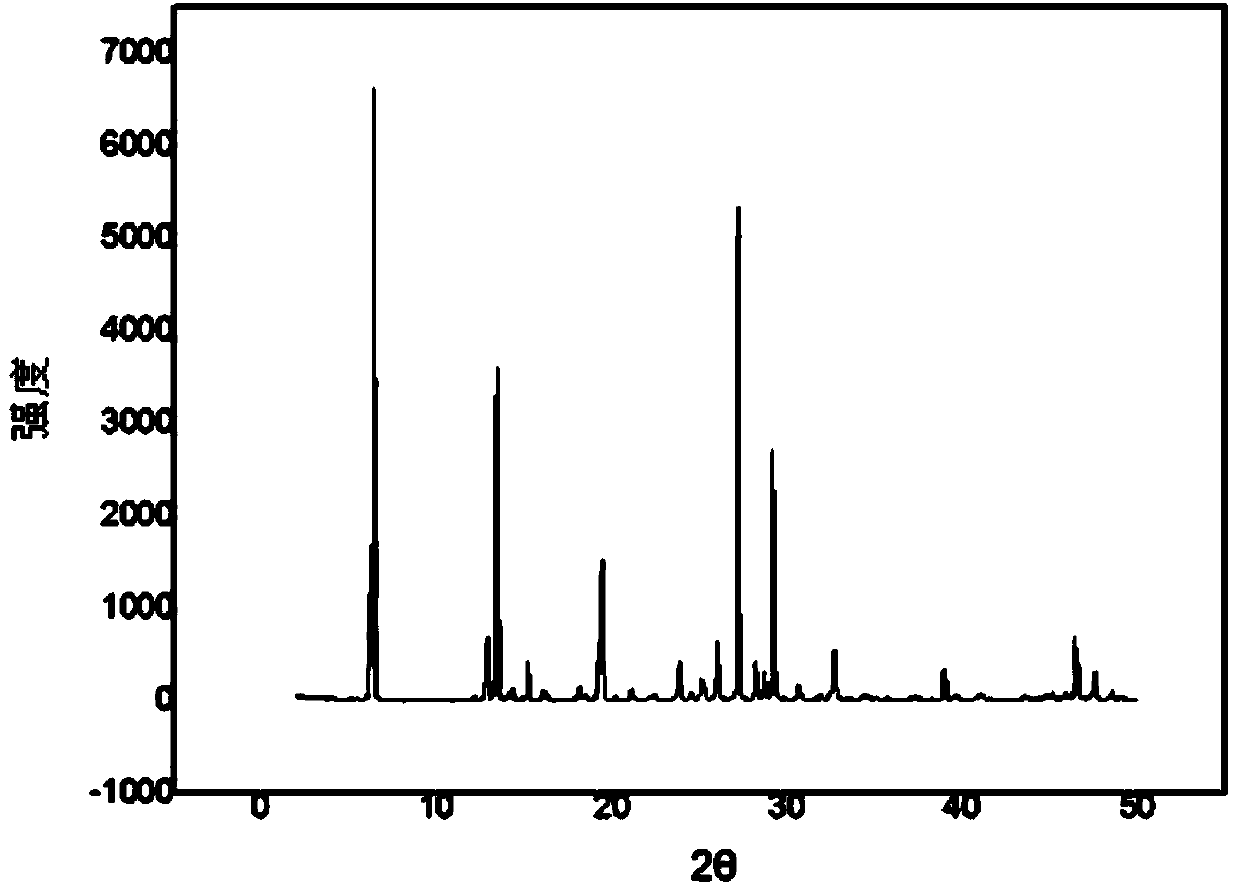

[0030] The TG and DSC of the obtained chloramine T crystals are shown in figure 1 , see XRD figure 2 , the crystal morpholog...

Embodiment 2

[0032] A method for preparing large particle chloramine T based on cooling crystallization, comprising the following steps:

[0033] (1) Weigh 30g of chloramine T, add it to 180mL ethanol aqueous solution (the volume ratio of ethanol and water in the ethanol aqueous solution is 6:1), heat to 50°C, and stir to dissolve;

[0034] (2) Pour into a jacketed reactor with controllable stirring, stir at 220rpm, cool the solution obtained in step (1) until crystallization is cloudy, and add 0.3g of chloramine T crystal to the cloudy solution at 35°C Seed, grow the crystal for 30 minutes, gradually increase the cooling rate, and drop it to 10°C in 5 hours to obtain a crystal suspension;

[0035] (3) Filter the crystal suspension obtained in step (2) and dry it naturally to obtain large particles of chloramine T. The yield is 68%.

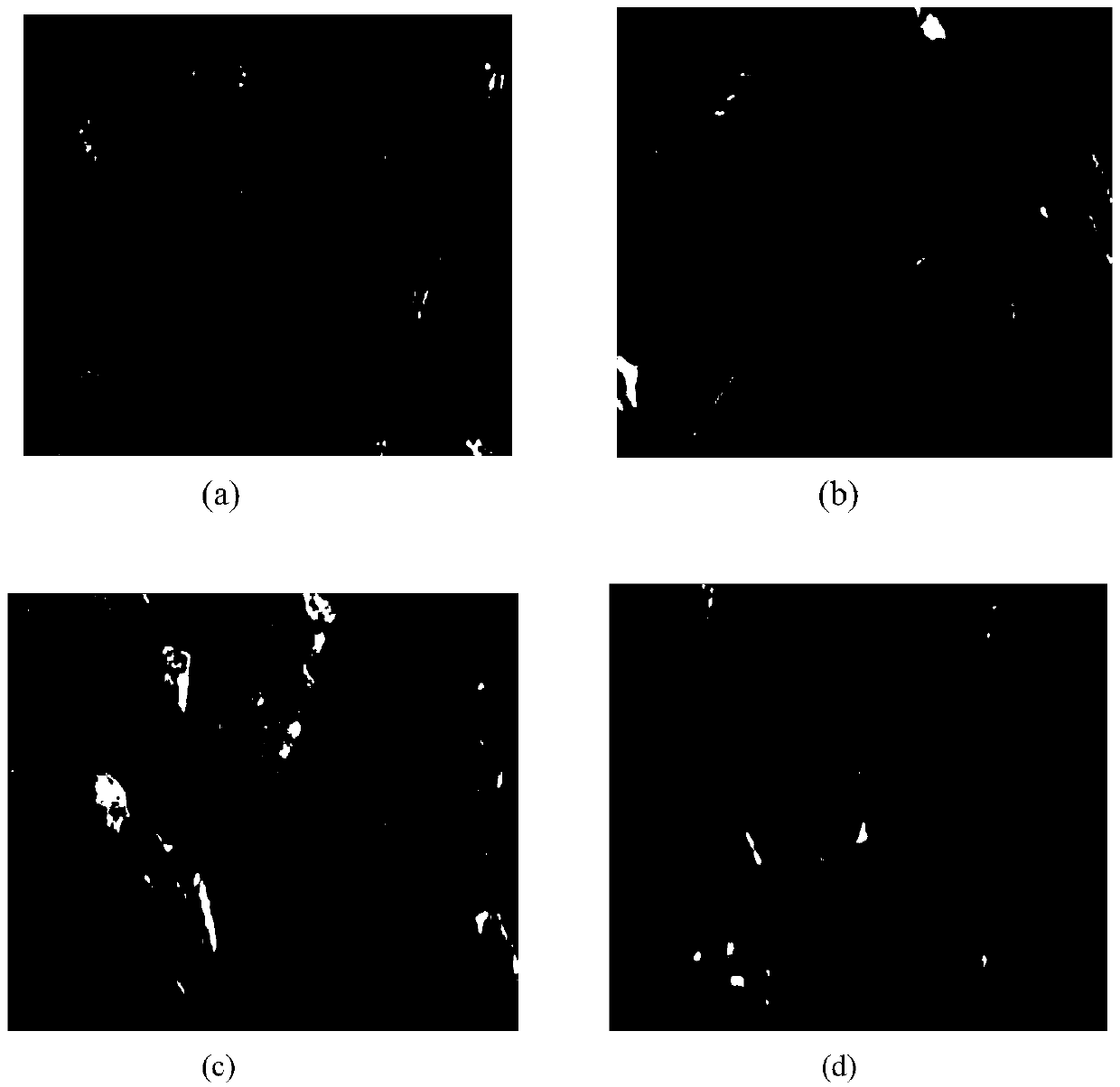

[0036] The crystal form seen under the microscope of the obtained large particle chloramine T product is as follows image 3 As shown in (b), the TG and D...

Embodiment 3

[0038] A method for preparing large particle chloramine T based on cooling crystallization, comprising the following steps:

[0039] (1) Weigh 25g of chloramine T, add it to 175mL ethanol aqueous solution (the volume ratio of ethanol and water in the ethanol aqueous solution is 5:1), heat to 50°C, and stir to dissolve;

[0040] (2) Pour into a jacketed reactor with controllable stirring, stir at 220rpm, cool the solution obtained in step (1) until crystallization is cloudy, and add 0.5g chloramine T to the cloudy solution at 30°C Seed crystals, grow crystals for 20 minutes, gradually increase the cooling rate, and drop to 8°C in 7 hours to obtain a crystal suspension;

[0041] (3) Filter the crystal suspension obtained in step (2) and dry it naturally to obtain large particles of chloramine T. Yield 72%.

[0042] The crystal form seen under the microscope of the obtained large particle chloramine T product is as follows image 3 As shown in (c), the TG and DSC of the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com