Preparation method of diesel oil pour point depressant containing styrene-fumaric acid copolymer

The technology of fumaric acid copolymer and fumaric acid copolymer is applied in the field of oil additives, and can solve the problems of no obvious improvement, insignificant improvement effect of cooling point, poor biodiesel susceptibility, and the like, To achieve the effect of effective cooling point, good stable dispersion, preventing crystal formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

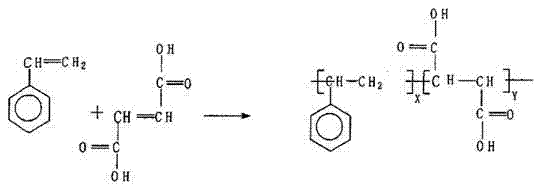

[0030] Put 1 mol of fumaric acid into the flask, connect condensed water, add 4 mol of benzene, start stirring at a stirring speed of 150r / min, heat to dissolve, then add 1 mol of styrene into the dropping funnel, and add 1 mol of benzene peroxide Dissolve formyl in 4mol benzene and put it in the dropping funnel, wait for the temperature to reach 80°C, start adding benzoyl peroxide and styrene dropwise, control the dropping speed, finish adding in 1 h, and then react for 1 h to get white flocculent substance. The reaction mixture was separated and filtered with ethanol, and dried in an oven to obtain styrene-fumaric acid copolymer S-FU.

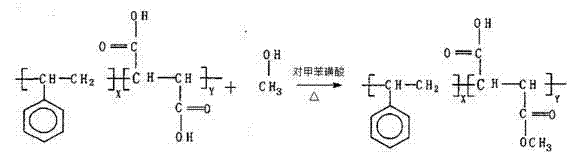

[0031] Add 1 mol of S-FU, 1 mol of methanol, 0.2 mol of p-toluenesulfonic acid, and 0.5 mol of toluene as a solvent into the flask, install the condenser and pass condensed water, start stirring and heating, and react at 120°C for 1.5 hours to obtain mono Ester S-FU-Dx.

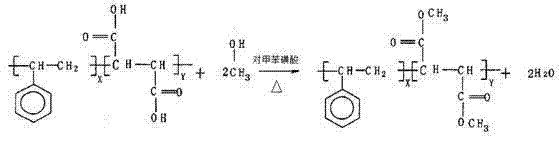

[0032] Add 1 mol of S-FU, 1 mol of methanol, 0.2 mol of p-toluenesulf...

Embodiment 2

[0035] Put 1 mol of fumaric acid into the flask, connect condensed water, add 4.5 mol of benzene, start stirring at a stirring speed of 200r / min, heat to dissolve, then add 1 mol of styrene into the dropping funnel, and 1 mol of peroxidized Dissolve benzoyl in 4.5 mol of benzene and put it into the dropping funnel, wait until the temperature reaches 90°C, start adding benzoyl peroxide and 1 mol of styrene dropwise, control the rate of addition, finish adding in 1 h, and then react for 1 h, A white flocculent substance was obtained. The reaction mixture was separated and filtered with ethanol, and dried in an oven to obtain styrene-fumaric acid copolymer S-FU.

[0036] Add 1 mol of S-FU, 1 mol of methanol, 0.2 mol of p-toluenesulfonic acid, and 0.5 mol of toluene as a solvent into the flask, install a condenser and pass condensed water, start stirring and heating, and react at 120°C for 2 hours to obtain a monoester Compound S-FU-Dx.

[0037] Add 1 mol of S-FU, 1 mol of metha...

Embodiment 3

[0040] Put 1 mol of fumaric acid into the flask, connect condensed water, add 5 mol of benzene, start stirring at a stirring speed of 200r / min, heat to dissolve, then add 1 mol of styrene into the dropping funnel, and add 1 mol of benzene peroxide Dissolve formyl in 5 mol of benzene and put it in the dropping funnel, wait for the temperature to reach 95°C, start to drop benzoyl peroxide and 1 mol of styrene, control the rate of addition, finish adding in 1 h, and then react for 1 h to obtain white flocculent substance. The reaction mixture was separated and filtered with ethanol, and dried in an oven to obtain styrene-fumaric acid copolymer S-FU.

[0041]Add 1 mol of S-FU, 1 mol of methanol, 0.2 mol of p-toluenesulfonic acid, and 0.5 mol of solvent toluene into the flask, install the condenser and pass condensed water, start stirring and heating, and react at 120°C for 2 hours to obtain a monoester Compound S-FU-Dx.

[0042] Add 1 mol of S-FU, 1 mol of methanol, 0.2 mol of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com