Long glass fiber enhanced polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of long glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of poor reinforcement effect and short glass fiber aspect ratio, and achieve high dimensional stability, balanced mechanical properties, low creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

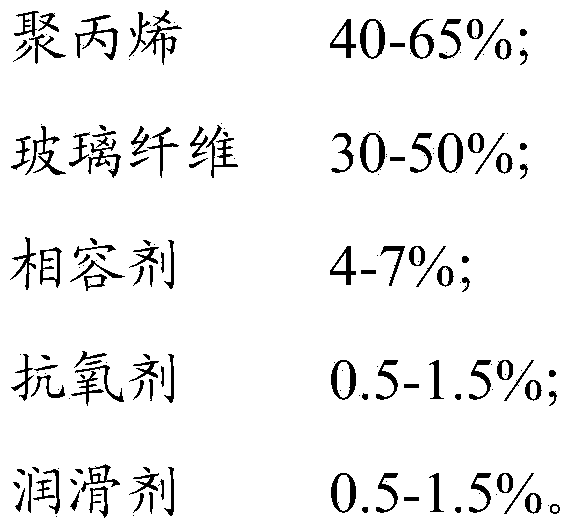

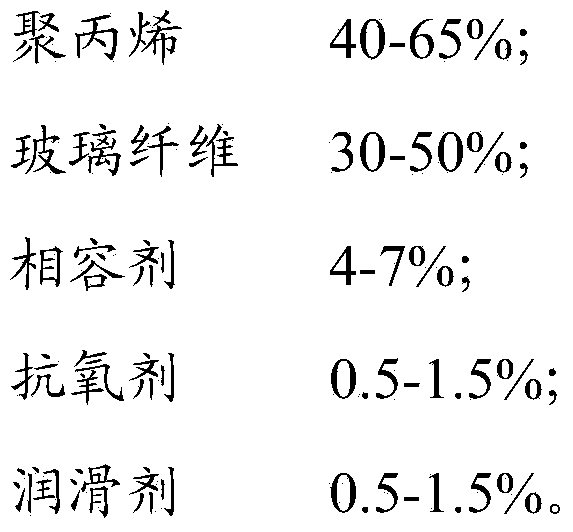

Method used

Image

Examples

preparation example Construction

[0024] Correspondingly, the embodiment of the present invention also provides a method for preparing the above-mentioned long glass fiber reinforced polypropylene composite material, the method comprising the following steps:

[0025] S01. Weigh the corresponding components: Weigh the polypropylene, compatibilizer lubricant and antioxidant components respectively according to the component content of the above-mentioned long glass fiber reinforced polypropylene composite material;

[0026] S02. Perform mixing treatment on the corresponding components: perform mixing treatment on the polypropylene, compatibilizer lubricant and antioxidant to obtain a mixed material;

[0027] S03. Disperse the long glass fibers in the molten mixture material and perform impregnation treatment to prepare long glass fiber reinforced polypropylene composite materials: melt the mixture material using an extruder and place it in the impregnation system, and then add long glass fibers to the impregnati...

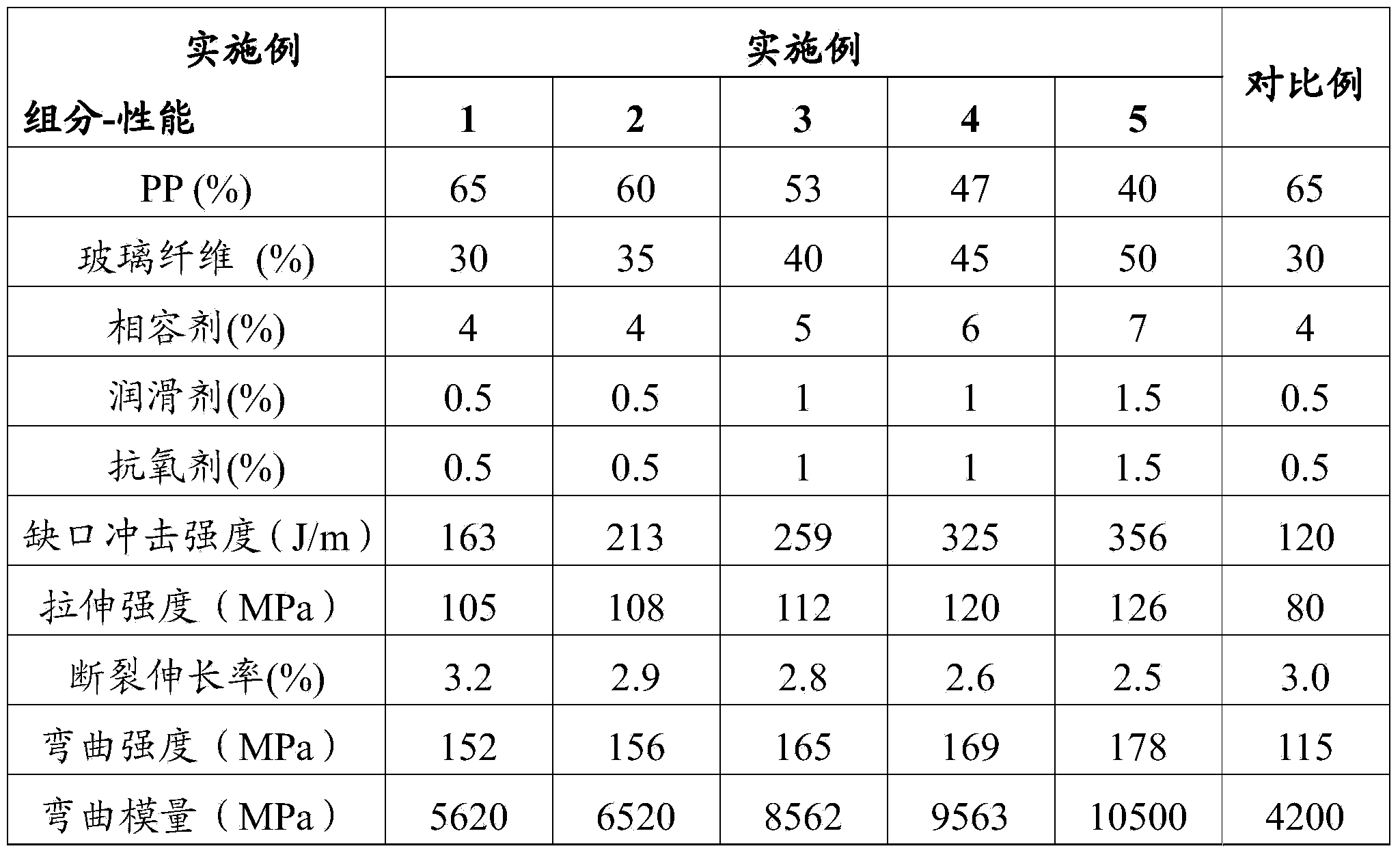

Embodiment 1

[0037] A preparation method of long glass fiber reinforced polypropylene composite material:

[0038] Mix PP with a weight ratio of 65% (the following are weight ratios), long glass fiber EDR17-2400-362K30%, compatibilizer 8010-MAH4%, antioxidant 0.5%, and lubricant 0.5% to mix evenly. Put the mixed materials into the hopper of the twin-screw extruder, the melted polypropylene and other raw materials are conveyed to the impregnation system of the machine head by the screw, and the long glass fibers enter the impregnation system from the die head, and pass through the impregnation system The surface is provided with chamfered protruding corners of the "product"-shaped rollers, and the long glass fibers are fully dispersed in the PP mixed melt and then drawn, cooled and granulated. Among them, the temperature of the first zone of the twin-screw extruder is 175-200°C, the temperature of the second zone is 180-210°C, the temperature of the third zone is 180-210°C, the temperature ...

Embodiment 2

[0041] A preparation method of long glass fiber reinforced polypropylene composite material:

[0042] The weight ratio of PP is 60% (the following are weight ratios), long glass fiber EDR17-2400-362K30%, compatibilizer 8010-MAH4%, antioxidant 0.5%, lubricant 0.5%. Put the mixed materials into the hopper of the twin-screw extruder, the melted polypropylene and other raw materials are conveyed to the impregnation system of the machine head by the screw, the long glass fiber enters the impregnation system from the die head, and the long glass fiber enters the impregnation system from the die head After entering the impregnation system, the long glass fibers are fully dispersed in the PP mixed melt by the "pin"-shaped rollers with chamfered raised corners on the surface of the impregnation system, and then drawn, cooled, and granulated. Among them, the temperature of the first zone of the twin-screw extruder is 175-200°C, the temperature of the second zone is 180-210°C, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com