Method for preparing special modifier for saline-alkali soil cotton fields from cotton stalks

A technology of saline-alkali soil and improver, applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve problems such as aggravating the spread of diseases and insect pests, and achieve the effects of suitable crop growth, simple ingredients and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

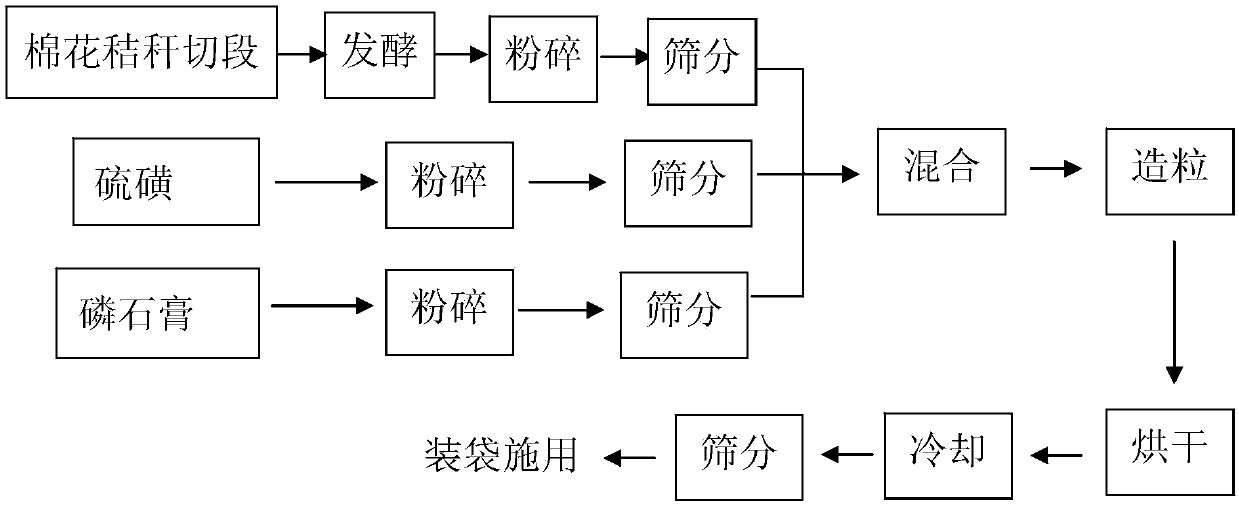

Image

Examples

Embodiment 1

[0036]Cut the cotton stalks into 6cm lengths and put them in the fermentation tank. Put the impregnation solution inoculated with cellulolytic enzymes into the tank for retting. The soaking solution soaks the cotton stalks and stirs them every 5 days. After 20 days, clean the cotton stalks. Come out, continue to pile up after 10 days, dry in the sun, pulverize, obtain fermented cotton stalk.

[0037] Phosphogypsum is commercially available phosphogypsum produced by Qingdao Laixi Phosphate Fertilizer Factory. Its main parameters are pH 2.55, CaO weight percentage 34.8%, SO 3 The weight percentage is 46.8%, SiO 2 The weight percentage is 5.5%, P 2 o 5 The weight percentage content of MgO is 3.2%, the weight percentage content of MgO is 2.5%, Al 2 o 3 The weight percent composition is 1.8%.

[0038] Sulfur and phosphogypsum are crushed into powders with a particle size of less than 1 mm for later use.

[0039] The above three materials are compounded according to the ratio ...

Embodiment 2

[0043] Cut the cotton stalks into 8cm lengths and put them in the fermentation tank. Put the soaking solution inoculated with cellulolytic enzymes into the tank for retting. The soaking solution soaks the cotton stalks and stirs them every 3 days. After 15 days, clean the cotton stalks. Come out, continue to pile up after 15 days, dry in the sun, crush, obtain fermented cotton stalk.

[0044] Phosphogypsum is commercially available phosphogypsum produced by Qingdao Laixi Phosphate Fertilizer Factory. Its main parameters are pH 2.55, CaO weight percentage 34.8%, SO 3 The weight percentage is 46.8%, SiO 2 The weight percentage is 5.5%, P 2 o 5 The weight percentage content of MgO is 3.2%, the weight percentage content of MgO is 2.5%, Al 2 o 3 The weight percent composition is 1.8%.

[0045] Sulfur and phosphogypsum are crushed into powders with a particle size of less than 1 mm for later use.

[0046] The above three materials are compounded according to the ratio of ferme...

Embodiment 3

[0050] Cut the cotton stalks into 5cm lengths, put them in the fermentation tank, put the impregnation solution inoculated with cellulolytic enzymes into the tank for stack retting, soak the cotton stalks in the soaking solution, stir it every 5 days, and clean the cotton stalks after 15 days Come out, continue to pile up after 15 days, dry in the sun, crush, obtain fermented cotton stalk.

[0051] Phosphogypsum is commercially available phosphogypsum produced by Qingdao Laixi Phosphate Fertilizer Factory. Its main parameters are pH 2.55, CaO weight percentage 34.8%, SO 3 The weight percentage is 46.8%, SiO 2 The weight percentage is 5.5%, P 2 o 5 The weight percentage content of MgO is 3.2%, the weight percentage content of MgO is 2.5%, Al 2 o 3 The weight percent composition is 1.8%.

[0052] Sulfur and phosphogypsum are crushed into powders with a particle size of less than 1 mm for later use.

[0053] The above three materials are compounded according to the ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com