Chain plate special for wear resistant steel ball aging furnace

A wear-resistant steel ball and aging furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of fragile structure, uniform distribution, easy ball jamming, etc., to achieve convenient maintenance and replacement, compact structure, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

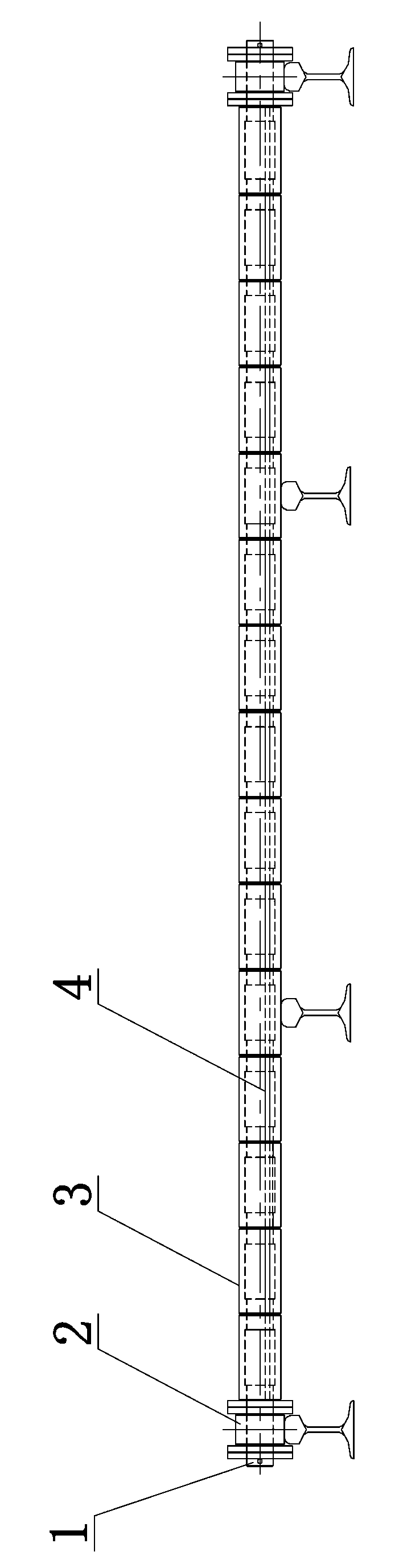

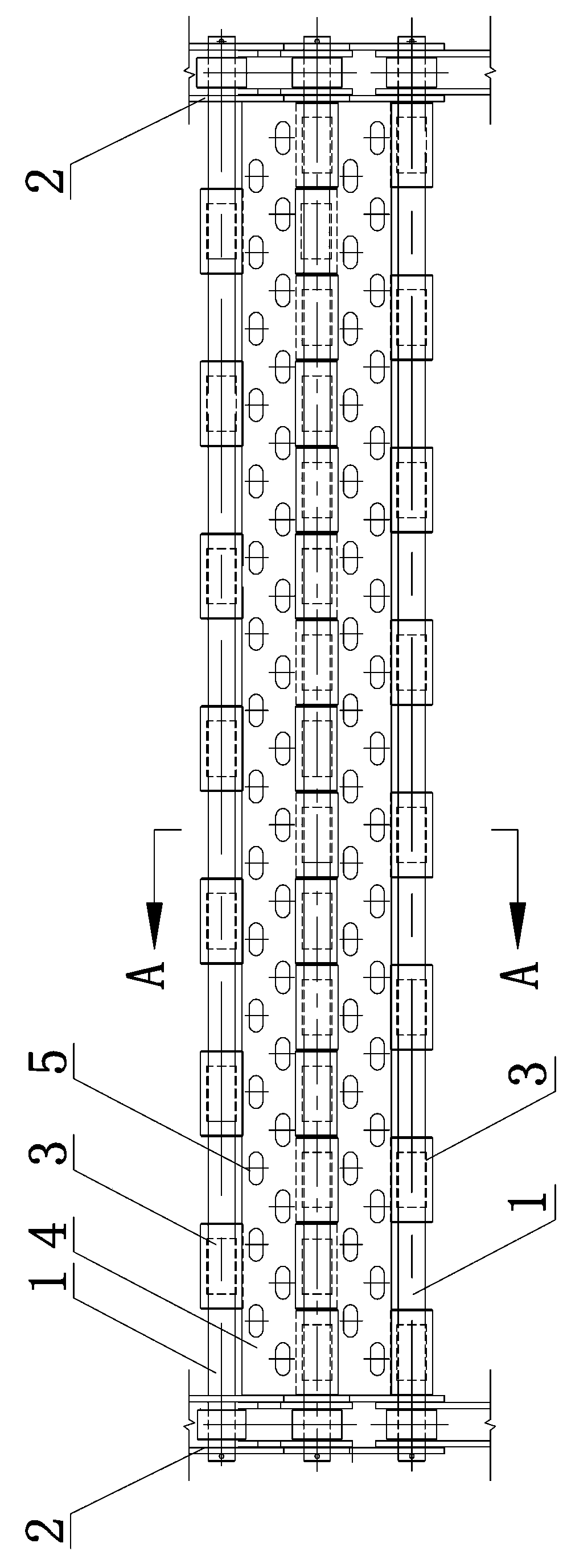

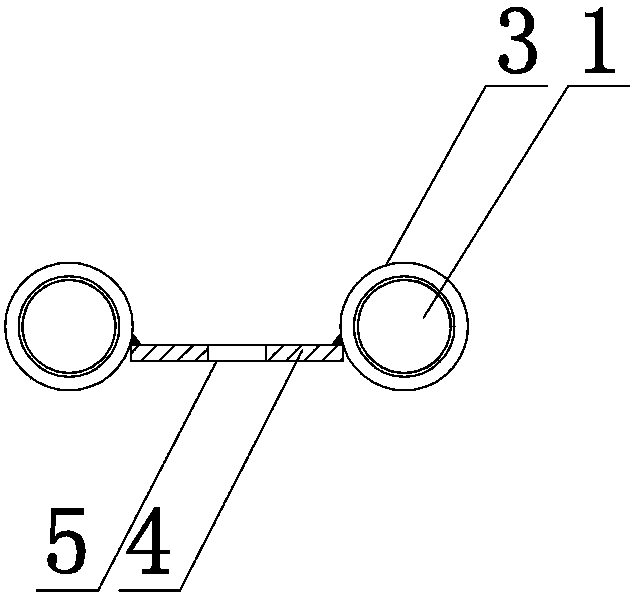

[0012] see figure 1 , 2 , 3, the present invention has several long shafts 1 arranged equidistantly (the long shafts are provided according to the total length of the ring chain), especially: ring chains 2 are installed at both ends of the long shafts 1, and between two long shafts 1 Equipped with perforated plates 4, each perforated plate 4 is welded with a number of bushes 3 arranged at intervals, and the bushes 3 on both sides are misplaced with each other, and all the bushes 3 correspond to the long axis 4 sets connect.

[0013] In this embodiment, the distance between the bushings 3 on each side of the perforated plate 4 is greater than or equal to the length of the bushings 3, which can be specifically designed as equal to or equal to.

[0014] In this embodiment, the perforated plate 4 is provided with two rows of elongated holes 5 , and the two rows of elongated holes 5 are arranged in an offset manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com