Synthetic Method of Confined-Growth Metal-Organic Framework Compound Flexible Film

A technology of metal organic framework and synthesis method, which is applied in the direction of filament/wire forming, conjugated synthetic polymer rayon, conjugated rayon, etc., can solve the difficulty of MOFs size control, application field limitation, poor formability, etc. problem, to achieve the effect of good industrial application prospects, short time consumption, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

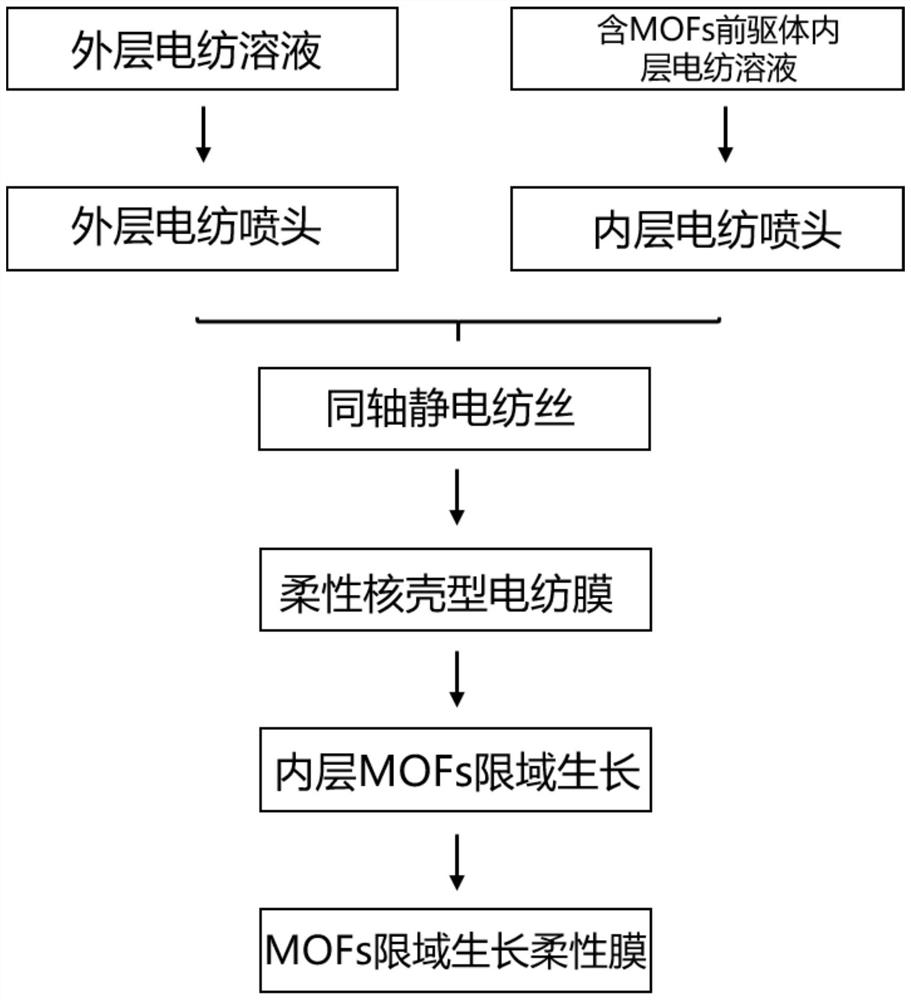

[0032] This example discloses a method for synthesizing a flexible film of a metal-organic framework compound grown in confinement, such as figure 1 shown, including the following steps:

[0033] 1) Preparation of electrospinning precursor solution: including outer layer precursor solution and inner layer precursor solution;

[0034] Preparation of the outer layer precursor solution (i.e. the outer layer electrospinning solution): dissolve the insoluble first high molecular polymer in the first solvent, and the mass concentration of the first high molecular polymer is 1% to 30%, Then a spinnable outer layer precursor solution is obtained, and the first high molecular polymer is within the mass concentration range, which can ensure that the electrospinning process can be carried out smoothly; wherein, the first high molecular polymer is polyacrylonitrile, polybias Any one of vinyl fluoride, polystyrene, polymethyl methacrylate, nylon 66, chitosan and cellulose, this series of...

Embodiment 1

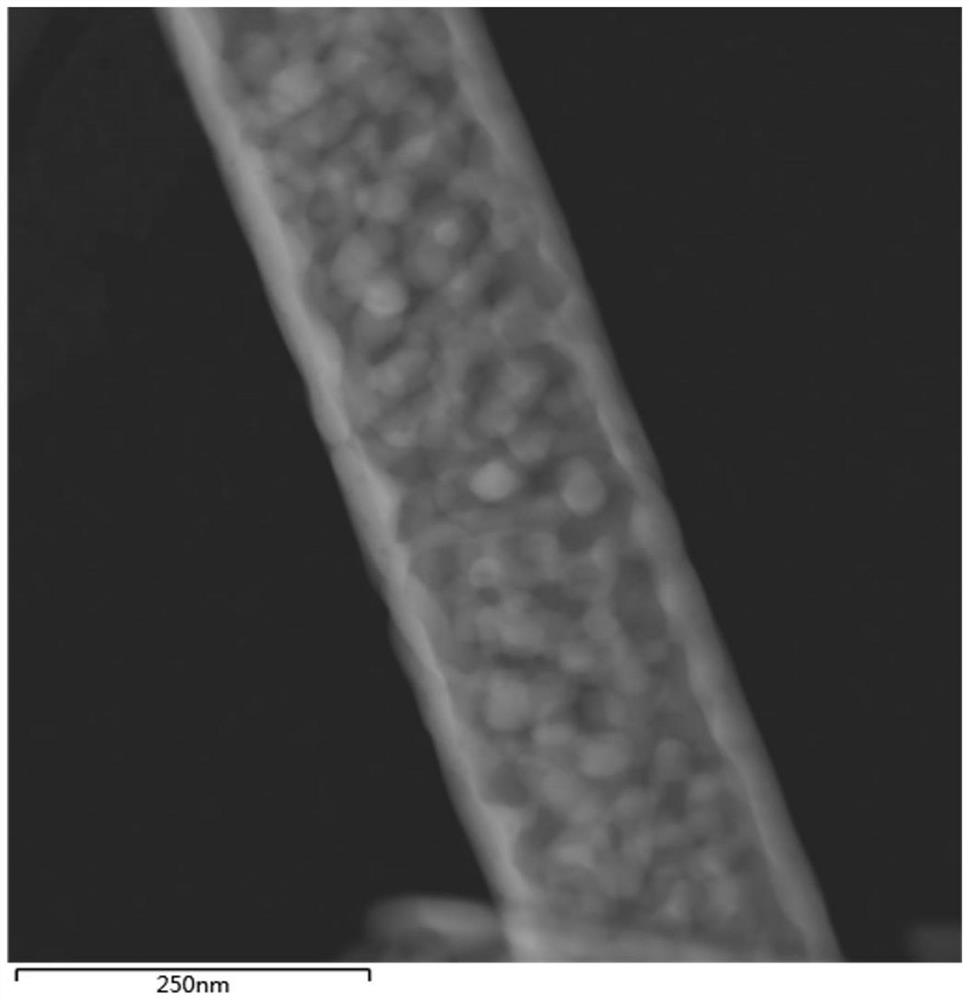

[0044] Weigh 0.8g of polyacrylonitrile and dissolve it in 10g of N,N-2 methylamide, stir evenly at room temperature to obtain an outer layer electrospinning solution with a concentration of 8%; weigh 0.75g of polyvinylpyrrolidone, 0.60g of bismuth nitrate 1.2 g of trimesic acid was dissolved in 20 g of methanol, and stirred evenly at room temperature to prepare an inner layer electrospinning solution. Pour the outer layer electrospinning solution into the outer layer electrospinning spinneret, pour the inner layer electrospinning solution into the inner layer electrospinning spinneret, and set the electrospinning parameters as follows: inner layer electrospinning spinneret diameter 0.3mm, shell electrospinning spinneret 0.8mm, inner layer electrospinning rate 0.5mL / h, outer layer electrospinning rate 1mL / h, electrospinning voltage set to 18kV, receiving distance 18cm, by Electrospinning obtains a core-shell precursor fiber (i.e. a coaxial core-shell flexible electrospinning pr...

Embodiment 2

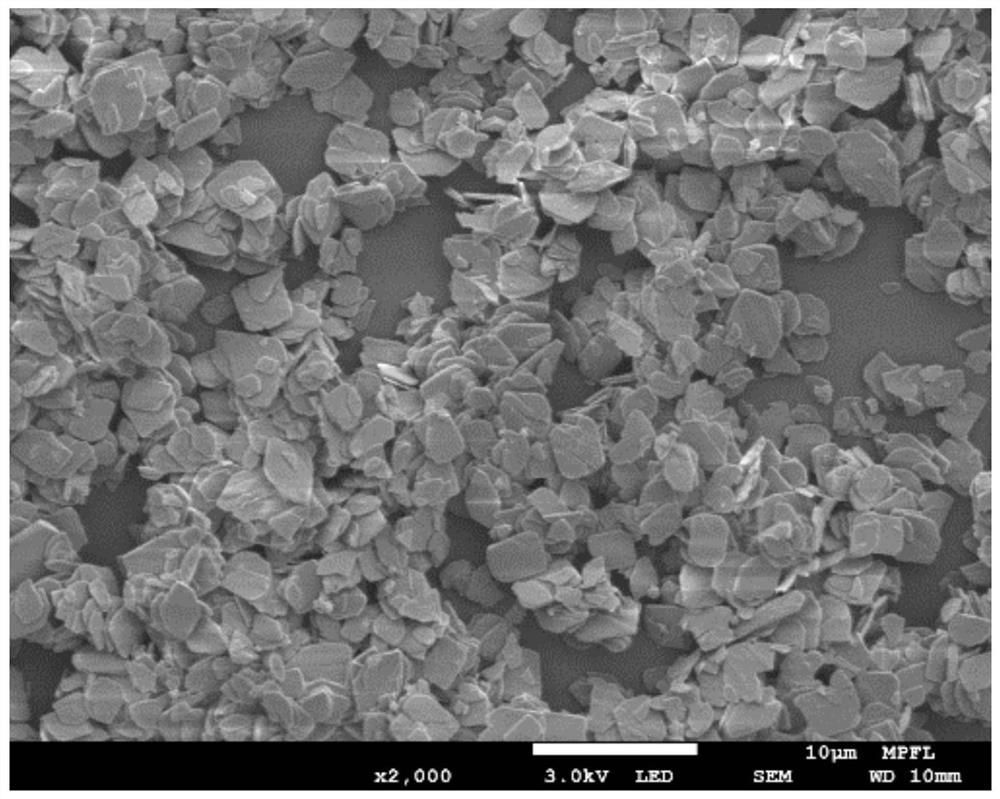

[0047] Weigh 1.50g of nylon 66 and dissolve it in 15g of formic acid solution, stir evenly at room temperature to obtain an outer layer electrospinning solution with a concentration of 10%; weigh 0.75g of polyvinyl alcohol, 0.30g of cobalt nitrate, 2.4g of dimethyl Imidazole was dissolved in 15 g of deionized water, and stirred evenly at room temperature to prepare an inner layer electrospinning solution. Pour the outer layer electrospinning solution into the outer layer electrospinning spinneret, pour the inner layer electrospinning solution into the inner layer electrospinning spinneret, and set the electrospinning parameters as follows: inner layer electrospinning spinneret diameter 0.2mm, shell electrospinning spinneret 0.9mm, inner layer electrospinning rate 1mL / h, outer layer electrospinning rate 1mL / h, electrospinning voltage set to 20kV, receiving distance 15cm, through electrostatic Spin to obtain a coaxial core-shell type flexible electrospinning precursor film with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com