Method for preparing high-strength steel plate with thickness of 20 mm

A high-strength steel plate, controlled rolling and controlled cooling technology, applied in the field of high-strength steel, can solve the problems of the decline of cold forming performance and the increase of yield ratio of steel, and achieve the effect of stable production process, excellent comprehensive performance and improvement of tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

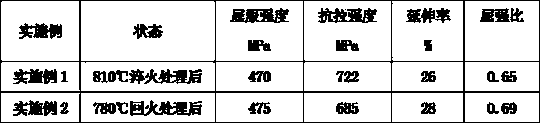

Embodiment 1

[0008] A method for preparing a 20mm thick high-strength steel plate. The method adopts the controlled rolling and controlled cooling process. The thickness of the continuous casting slab before rolling is 180mm, and the heating temperature is 1180°C; the chemical composition in the steel is calculated by weight percentage: C: 0.07%, Si: 0.18%, Mn: 1.30%, P: 0.010%, S: 0.005%, Ti: 0.011%, Cr: 0.10%, Ni: 0.15%, Cu: 0.20%, Al: 0.025%, and the balance is Fe and unavoidable impurities. Two-stage controlled rolling is adopted in the austenite recrystallization zone and austenite non-recrystallization zone, the reduction rate of each pass of rough rolling is 10-15%, the finishing temperature of rough rolling is 1000°C, and the rough rolling is 1.6-2.0 times the finished product The thickness of the intermediate billet; the starting temperature of finish rolling is 850°C, the reduction rate of each pass is 10-15%, the finish rolling temperature is 800°C; laminar cooling is adopted af...

Embodiment 2

[0010] A method for preparing a 20mm thick high-strength steel plate. The method adopts a controlled rolling and controlled cooling process. The thickness of the continuous casting slab before rolling is 200mm, and the heating temperature is 1200°C; the chemical composition in the steel is calculated by weight percentage: C: 0.09%, Si: 0.20%, Mn: 1.50%, P: 0.010%, S: 0.005%, Ti: 0.012%, Cr: 0.20%, Ni: 0.16%, Cu: 0.25%, Al: 0.030%, and the balance is Fe and unavoidable impurities. Two-stage controlled rolling in the austenite recrystallization zone and austenite non-recrystallization zone is adopted. The reduction rate of each rough rolling pass is 10-15%, the rough rolling finish rolling temperature is 1050°C, and the rough rolling is 1.6-2.0 times the finished product. The thickness of the intermediate billet; the starting temperature of finish rolling is 870°C, the reduction rate of each pass is 10-15%, the finish rolling temperature is 830°C; laminar cooling is adopted afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com