Waterproof and moisture permeable fabrics and production method thereof

A waterproof and moisture-permeable, production method technology, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of water pressure resistance limitation, poor lotus leaf effect, insufficient bulkiness, etc., and achieve good water pressure resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

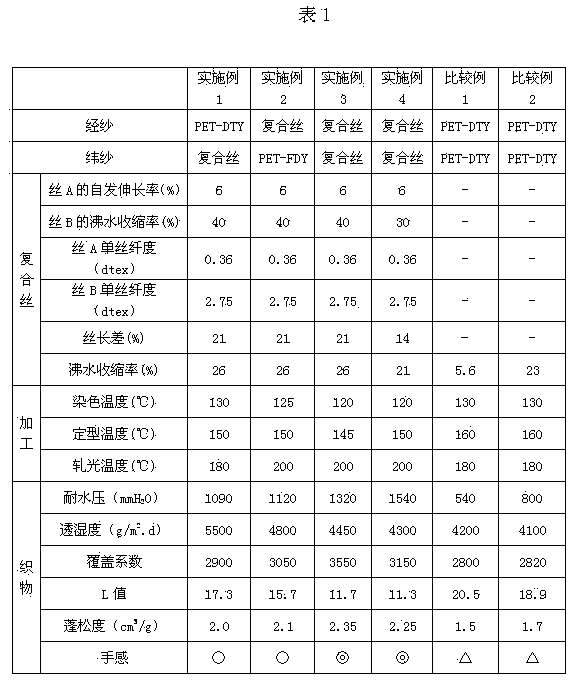

Embodiment 1

[0051] The warp yarn is 75D-144f-PET DTY, the weft yarn is 75D-108f-PET composite yarn (made from 35D-96f-POY and 33D-12f high-shrinkage yarn), plain weave is used, and the gray fabric is refined, dyed, and shaped, and is processed at the same time Water-repellent resin treatment and calendering treatment to obtain the finished product. The coverage factor of the finished product reaches 2900. It feels plump, soft and has a certain body. The initial water pressure resistance of JIS L 1092 (A) method reaches 1090mmH 2 O, moisture permeability is 5500g / m 2 .d. The L value of black processing dyeing lightness is 17.3.

[0052] Key Process Parameters

[0053] The dyeing temperature is 130°C, the setting temperature is 150°C, the calendering temperature is 180°C, and the line pressure is 2500N / CM. In addition, the water-repellent resin processing: the resin machine adopts the method of dipping and rolling. The fluorine-based water-repellent agent GS- 10 (trade name): 4.0G / L, cro...

Embodiment 2

[0055] The warp yarn is made of 75D-108f-PET composite yarn (35D-96f-POY and 33D-12f high-shrinkage yarn), the weft yarn is 75D-144f-PET FDY, and the 2 / 1 twill weave is used. The gray fabric is refined, dyed, and shaped At the same time, water-repellent resin treatment and calendering treatment are carried out to obtain the finished product. The coverage factor of the finished product reaches 3050. It feels plump, soft and has a certain body. The initial water pressure resistance of JIS L1092 (A) method reaches 1120mmH 2 O, moisture permeability is 4800g / m 2 .d. The black finish L value was 15.7.

[0056] Key Process Parameters

[0057] The dyeing temperature is 125°C, the setting temperature is 150°C, the calendering temperature is 200°C, and the line pressure is 2500N / CM. In addition, water-repellent resin processing: the resin machine adopts one dipping and one rolling method. The fluorine-based water-repellent agent GS- 10 (trade name): 4.0G / L, cross-linking agent NEO p...

Embodiment 3

[0059] The warp and weft yarns are made of 75D-108-PET composite yarn (made from 35D-96f-POY and 33D-12f high-shrinkage yarn), using 2 / 1 twill weave, and the gray fabric is refined, dyed, shaped, and treated with water-repellent resin and The finished product obtained by calendering treatment has a coverage factor of 3550. It feels plump, soft and has a certain body. The initial water pressure resistance of JIS L1092 (A) method reaches 1320mmH 2 O, the moisture permeability is 4450g / m2.d. The black finish L value was 11.7.

[0060] Key Process Parameters

[0061] The dyeing temperature is 120°C, the setting temperature is 145°C, the calendering temperature is 200°C, and the line pressure is 2500N / CM. In addition, the water-repellent resin processing: the resin machine adopts the method of dipping and rolling. The fluorine-based water-repellent agent GS- 10 (trade name): 4.0G / L, cross-linking agent NEO produced by Mingcheng Chemical Co., Ltd.: 1.0G / L, isopropanol (soaking age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com